with moisture content over 15%. Temperature and heating time in each step have to be

adjusted by tests.

16.5. Drying Time

Drying time is set by selecting one of available finish mode criteria. This means that a

moisture analyzer must meet pre-set criterion (mass over time, time) to automatically finish

the drying process. Finish of drying process can be triggered by amount of time,

independently on loss in mass. This criterion is used for substances that may decompose

during drying process, and their mass does not reach constant value. The second criterion is

loss in mass (less than 1 mg) in defined amount of time.

Finish modes:

Automatic- you can select various types of finish mode:

- Automatic 1 (change 1mg/10s).

- Automatic 2 (change 1mg/25s).

- Automatic 3 (change 1mg/60s).

- Automatic 4 (change 1mg/90s).

- Automatic 5 (change 1mg/120s).

Time defined- the drying process is finished after specified time, independently of the result.

(max drying time 99hours 59minutes).

Manual- the operator ends drying process manually by pressing START/STOP key

User defined - criteria determined by the operator. The operator determines the limit value

for loss of mass and time in which the loss of mass must not exceed a pre-set value. As the

moisture analyzer reaches the set criterion it automatically finishes the drying process.

- User defined 1 (Δm – change of mass in mg and Δt – change of time in seconds, max 120

s)

- User defined 2 (set moisture content change ratio Δ%M/60s)

Test - (enables selection of the auto switch-off parameters for a given sample)

16.6. Drying Profile Analysis

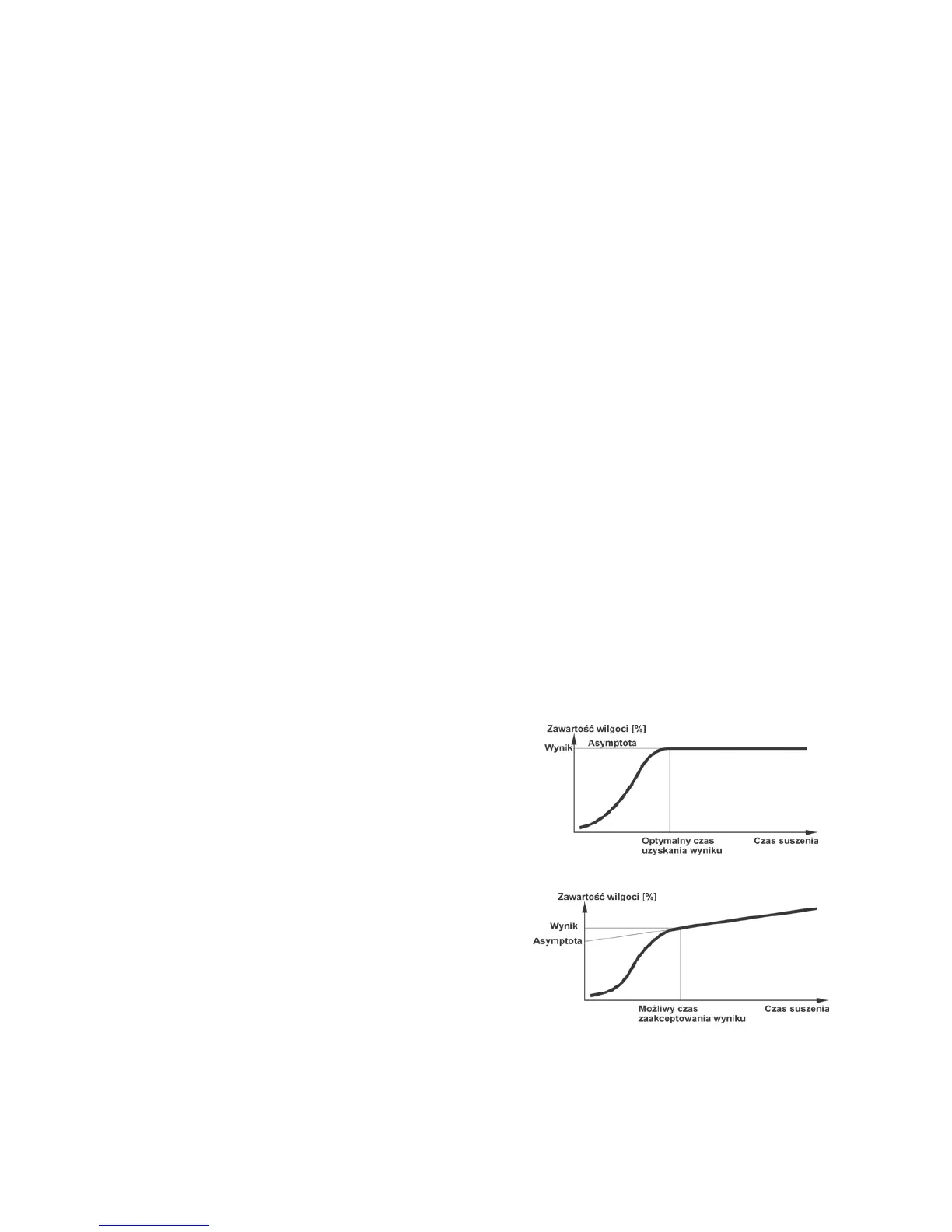

For the first case, the drying profile is an asymptote.

Moisture content value remains constant even after

long drying time.

Using this drying profile, the drying process results

are repeatable. The measurement result is always

referred to constant value of asymptote.

The result corresponds easily and it is not difficult to

select a proper criterion of finish mode.

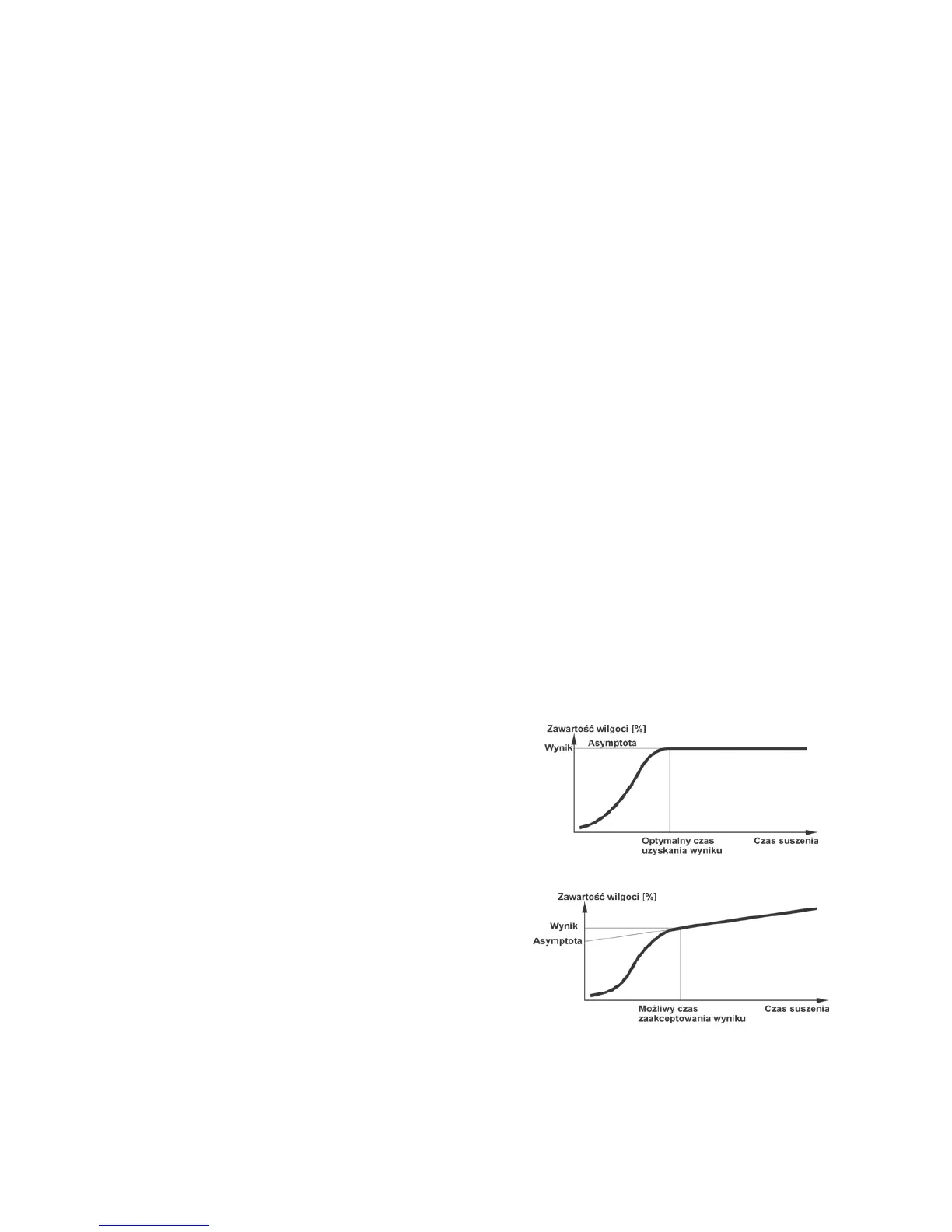

For the second case the drying process is quick at

the beginning, next it stabilizes. Moisture content

value is never constant. The properties of the

sample may cause it.

The sample undergoes thermal decomposition,

wherein evaporation takes place and as a result the product weigh decreases. Evaporation

of grease, oil, plastic or other volatile materials may take much more time than in case of

water. Difficult to evaporate materials drop weight.

Result obtained using this mode may be optimized by:

• lowering drying temperature to slower the distribution of ingredients.

Loading...

Loading...