Liquid substances

Semi-fluid substances are dried in their natural form. Large

amount of grease (fat) occurring in some of substances makes

moisture content determination difficult. In such case it is

recommended to use additional components, which increase

sample’s active surface and aid moisture content releasing

process from a sample. Such components are: high-silica sand,

blotting paper and filter. Prior to drying, initially dry the additional

component, so that its humidity is close to zero.

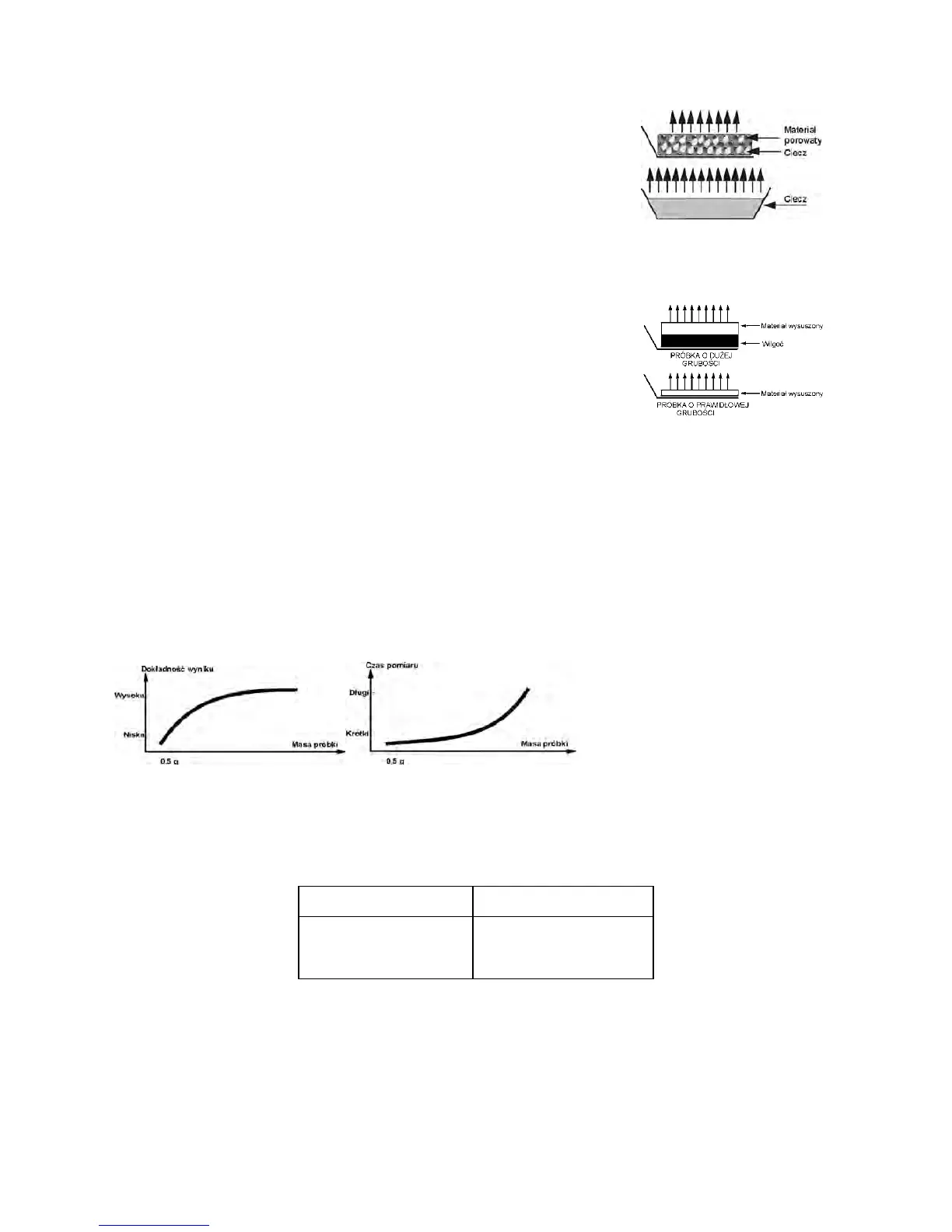

Solid substances

Depending on solid object’s structure (dense or loose), moisture

content determining process may take short or long time. The size

of solid’s surface determines the speed of drying process, and

measurement reliability. Thus, the surface of a solid object should

be as large as possible. Since solid objects release moisture

through their outer surface, sample thickness is another important

factor.

16. SELECTION OF DRYING PROCESS PARAMETERS

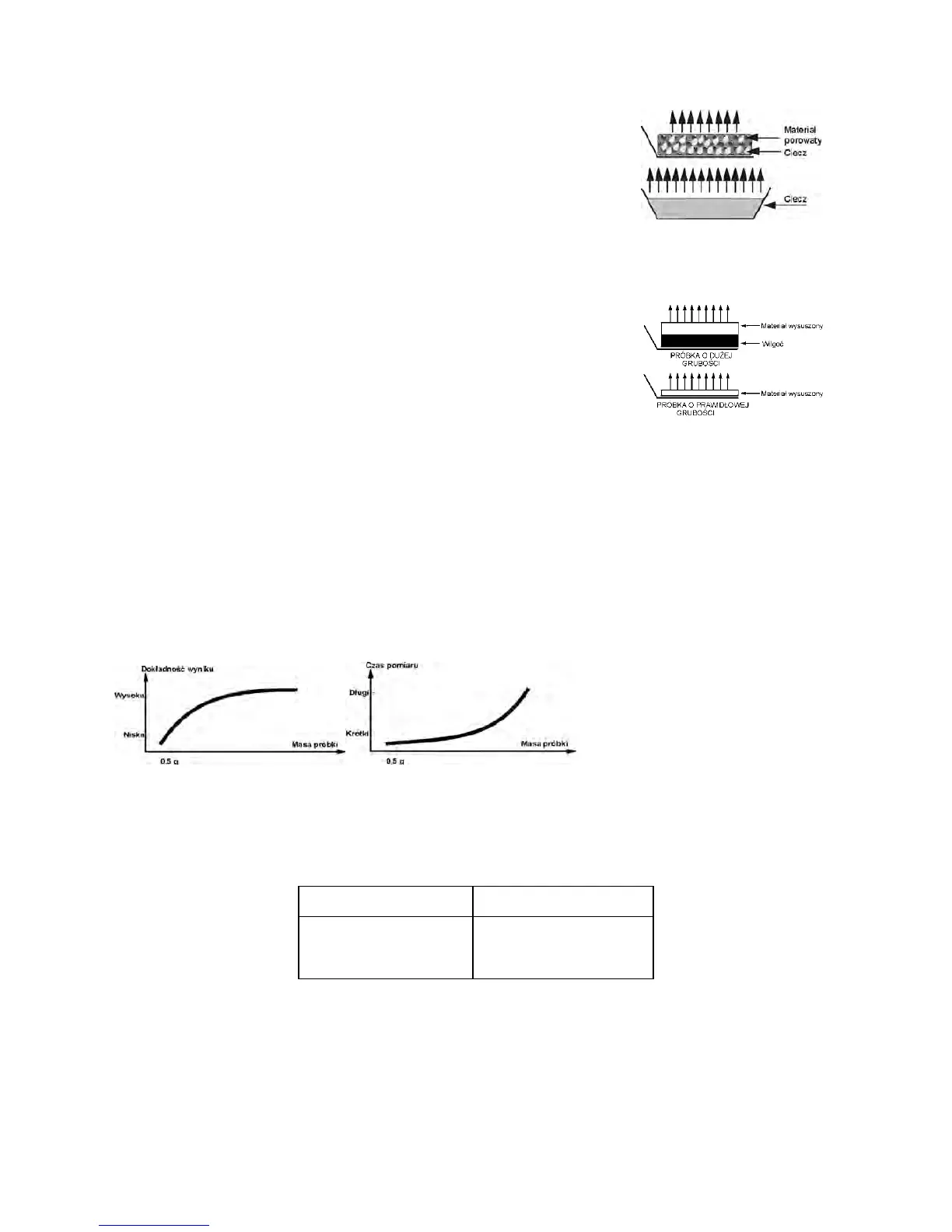

16.1. Optimum Sample Mass

Sample mass influences the accuracy of measurement result and measurement time. Higher

mass of a sample causes higher amount of water (moisture content) which needs to

evaporate, and therefore the measurement takes more time.

Obtaining short measurement time is possible in case of small sample mass, but sample

mass cannot be too small, as it may negatively influence required measurement accuracy.

16.2. Influence of Sample Mass on Measurement Repeatability

Sample mass considerably influences repeatability of measurement results obtained on a

moisture analyzer. Relation between sample mass and repeatability is presented in a table

below.

The above data refers to a model, uniform sample, containing no moisture due to the

evaporation process and showing no signs of decomposition (e.g. wet high-silica sand).

The results uncertainty cannot be avoided, this is due to sample nature and moisture

analyzer repeatability. In practice, it means that obtained measurement result may exceed

repeatability values provided above.

Loading...

Loading...