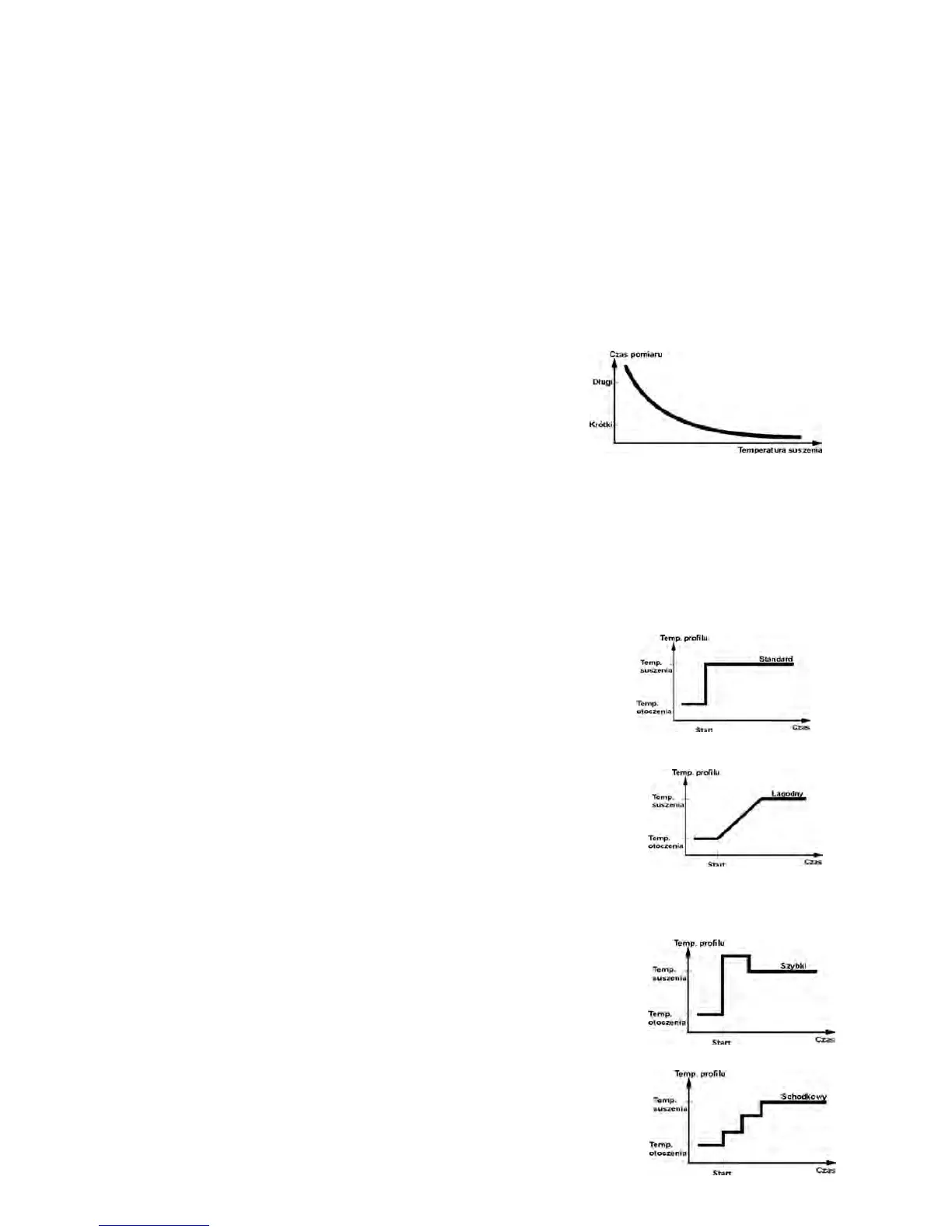

16.3. Drying Temperature

Drying temperature has the largest impact on drying time. Temperature value depends on

type of dried substance. Too low drying temperature causes too low moisture content

evaporation (under-dried sample), and consequently unnecessary extending of

measurement time. Too high drying temperature causes burning of dried sample (sample

overheating, chemical decomposition). Drying temperature of traditional method (using a

furnace) is specified in applicable industry or company standards. Unless standards apply,

then temperature should be adjusted by tests.

When selecting drying temperature value, proceed as follows:

• Determine sample moisture content

• Determine temperature of substance chemical decomposition by tests

• Compare result obtained using a moisture analyzer with the one of traditional method

When drying a sample with high moisture content, it is

possible to shorten measurement time by selecting quick

or step drying mode. In such case, the majority of moisture

content is released when the drying temperature is higher

than set. Only after some time, the temperature is lowered

to the set value, and maintained until completing drying

process.

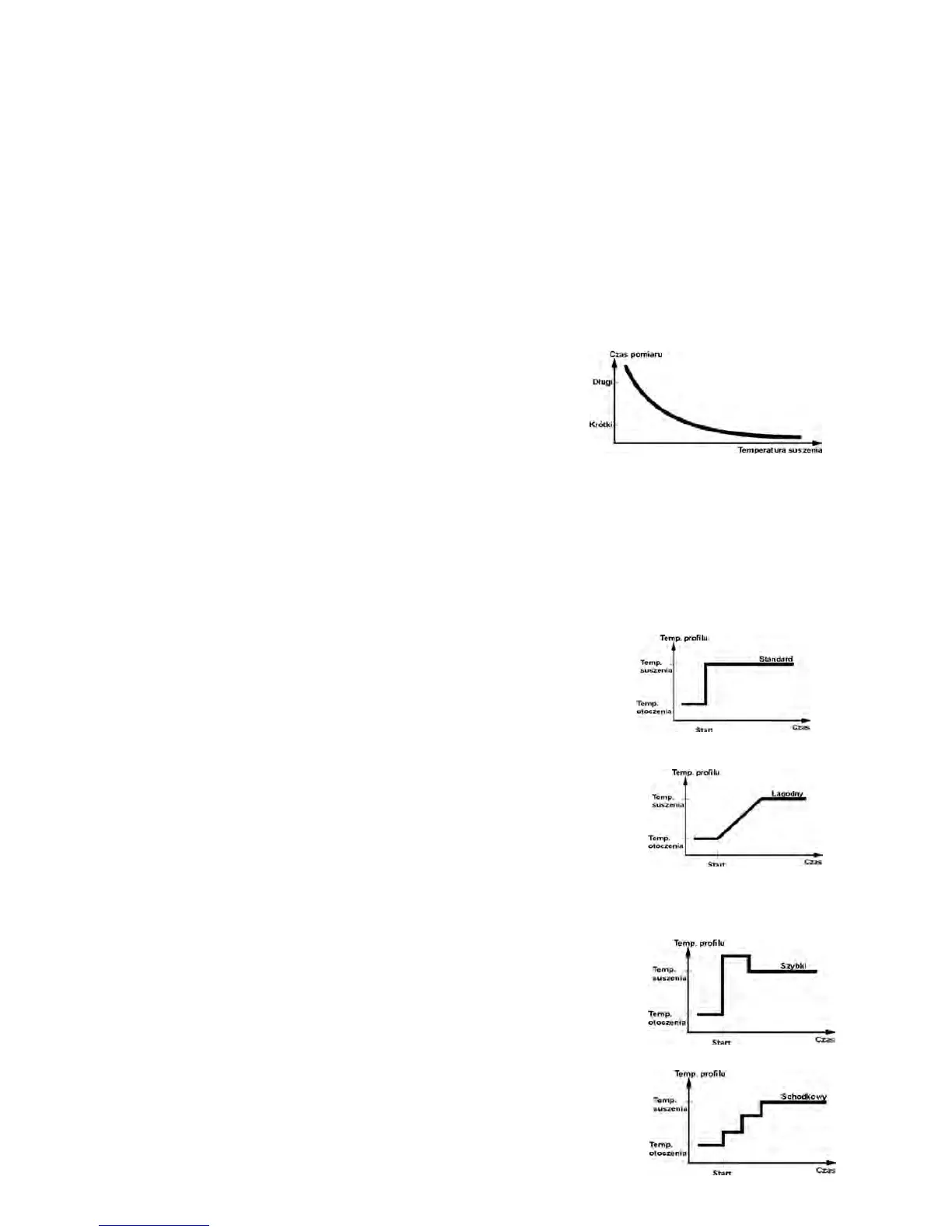

16.4. Drying Profile Selection

You can select one of four drying profiles:

• Standard

• Fast

• Mild

• Step

STANDARD profile

Standard profile is the most frequently used of all drying profiles.

It enables accurate determining of moisture content in a dried

sample.

MILD profile

Mild profile is used in case of drying substances that are sensitive

to rapid heat emitted by filaments operating at full power in the

initial stage of drying process. This profile prevents from

decomposing of substances sensitive to heat by mild temperature

increase in set amount of time (time interval has to be selected by

tests). Mild profile is recommended to drying samples of leather

structure.

FAST profile

Fast profile is recommended to drying samples that moisture

content varies from 5% to 15%. In the initial stage of Fast profile,

heating takes place at full power of the filaments, causing heating

the drying chamber to increased temperature, higher than the

drying temperature. Overheating compensates heat loss during

evaporation of large moisture content in the test’s initial stage.

STEP profile

Enables determining up to three steps with random drying

temperature. Step profile is recommended for drying substances

Loading...

Loading...