Section 04 ENGINE (2-STROKE)

Subsection 04 (TOP END)

Remove cylinder head no. 2.

If shells, sand, salt water or any other particles

are present in cylinder cooling jacket, clean with

a vacuum cleaner.

947 DI Engines

Disconnect hose of RAVE valves. Remove air/fuel

rail. Refer to ENGINE MANAGEMENT.

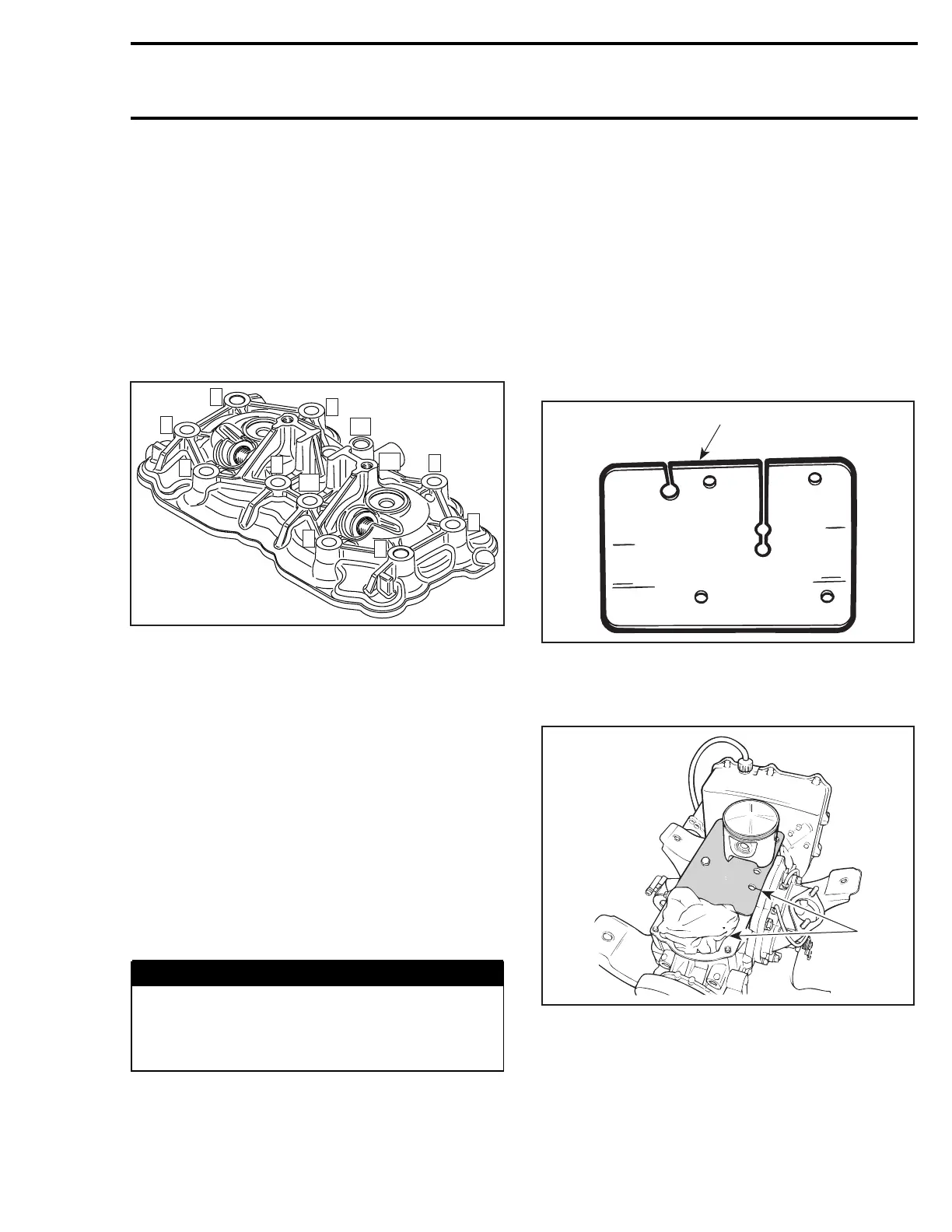

Use Snap-On Torx socket E12 and unscrew cylin-

der head screws no. 14 following the sequence

shown in the next illustration.

F12D08B

2

6

1

5

11

10

8

4

3

7

12

9

Remove cylinder head no. 2 and gasket no. 34.

Cylinder

NOTE: When removing cylinder, make sure con-

necting rods do not hit crankcase edge.

787 RFI Engines

Remove air intake silencer and support, refer to

AIR INTAKE.

717 and 787 RFI Engines

Remove tuned pipe and exhaust manifold, refer to

EXHAUST SYSTEM.

Remove screws no. 13.

Remove cylinders no. 9, while making sure con-

necting rods do not hit crankcase edge.

WARNING

If screws need to be heated for removal when

engine is in watercraft, fuel system pressur-

ization must be done first. Do not use open

flame; use a heat gun.

NOTE: Even if only 1 cylinder needs repair, both

cylinders should be lifted to allow 1-piece cylinder

base gasket replacement.

947 DI Engines

Remove cylinders screws then cylinders no. 9.

Piston

NOTE: All engines feature cageless piston pin

bearings.

717 and 787 RFI Engines

Bring piston to Top Dead Center and install rubber

pad (P/N 295 000 101) over crankcase opening.

Secure with screws. Lower piston until it sits on

pad.

F01B0JA

1

1. Rubber pad (P/N 295 000 101)

If the other cylinder has been removed, complete-

ly cover its opening with a clean rag.

F01D43A

1

1. Openings covered with rag and rubber pad

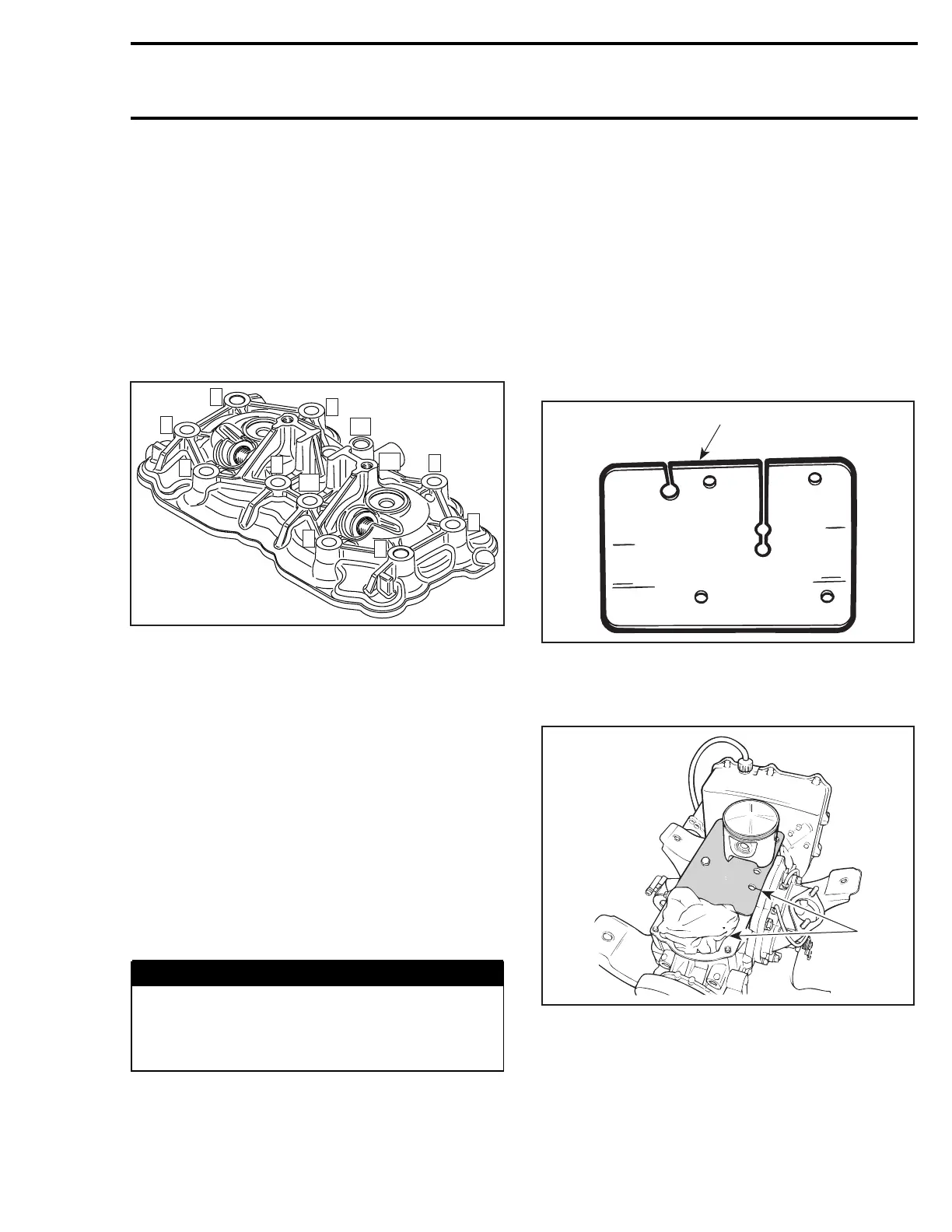

947 DI Engines

Install rubber pad (P/N 290 877 032) on crankcase.

Secure with screws. Lower piston to be removed

until it sits on pad.

smr2004-Complete Line Up 109

Loading...

Loading...