Section 05 ENGINE (4-TEC)

Subsection 05 (PTO HOUSING/MAGNETO)

Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

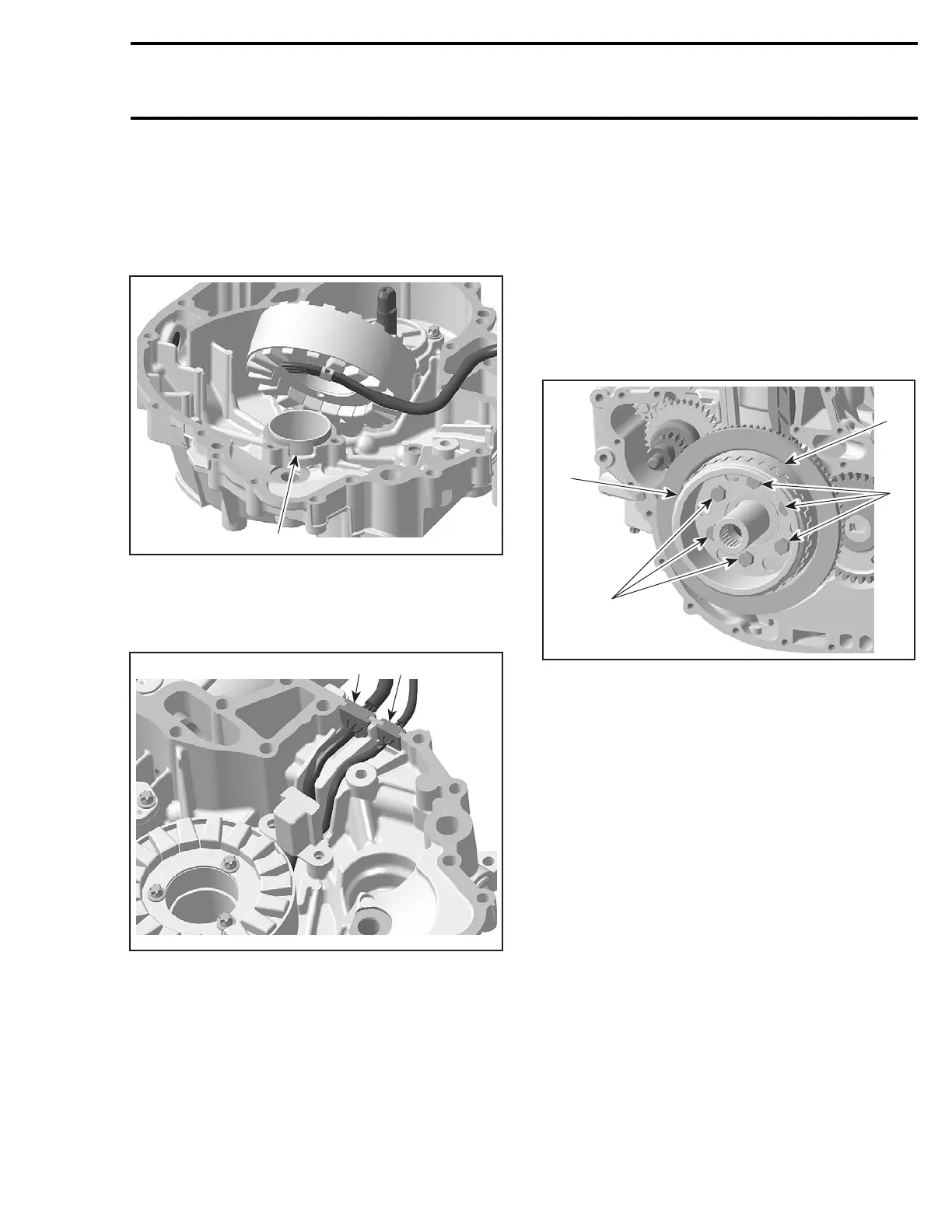

NOTE: There is only one position for the stator

(notch in the magneto housing cover).

1

R1503motr51A

TYPICAL

1. Notch for stator

Place the rubber grommets on both cables in the

proper notches at the PTO housing.

1

R1503motr52A

2

TYPICAL

1. Grommet on CPS cable

2. Grommet on stator cable

Apply Loctite 243 on threads. Torque stator and

CPSscrewsto10N•m(88lbf•in).

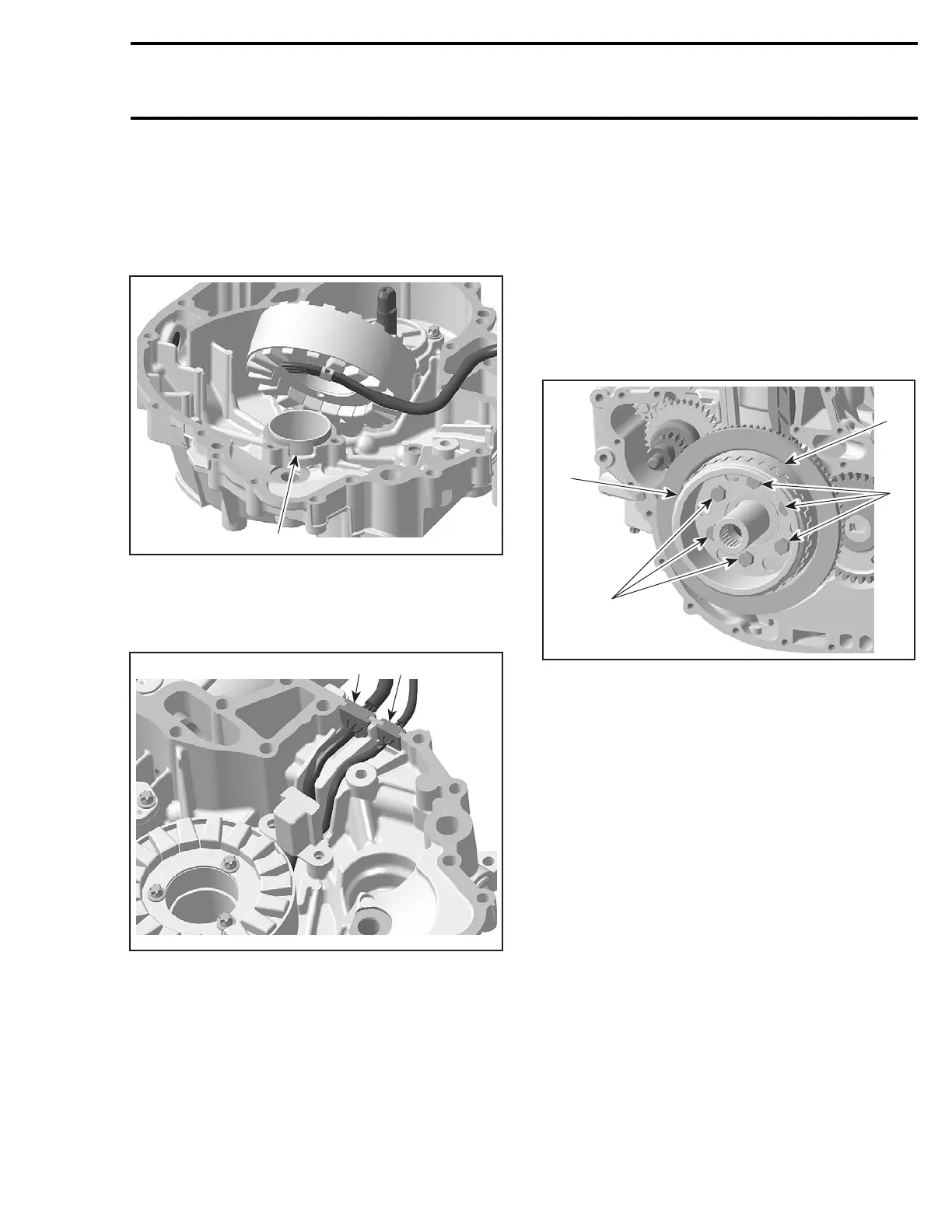

ROTOR AND ENCODER WHEEL

Removal

Lock crankshaft with locking tool (P/N 529 035

821). Refer to CRANKSHAFT LOCKING in EN-

GINE BLOCK subsection.

Remove:

– PTO housing

– hexagonal screws no. 18 retaining rotor.

Withdraw rotor no. 19 with encoder wheel no. 20.

1

R1503motr53A

2

3

1

TYPICAL

1. Hexagonal screws

2. Rotor

3. Encoder wheel

Inspection

Check rotor, bent teeth and encoder wheel condi-

tion. If damaged, replace faulty part.

Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

Encoder wheel position has to be located with the

location pin on the crankshaft gear.

Apply Loctite 243 on threads. Torque rotor screws

to 24 N•m(17lbf•ft).

RING GEAR

Removal

Lock crankshaft with locking tool (P/N 529 035

821). Refer to CRANKSHAFT LOCKING in EN-

GINE BLOCK subsection.

smr2004-Complete Line Up 231

Loading...

Loading...