Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

CRANKSHAFT POSITION

SENSOR (CPS)

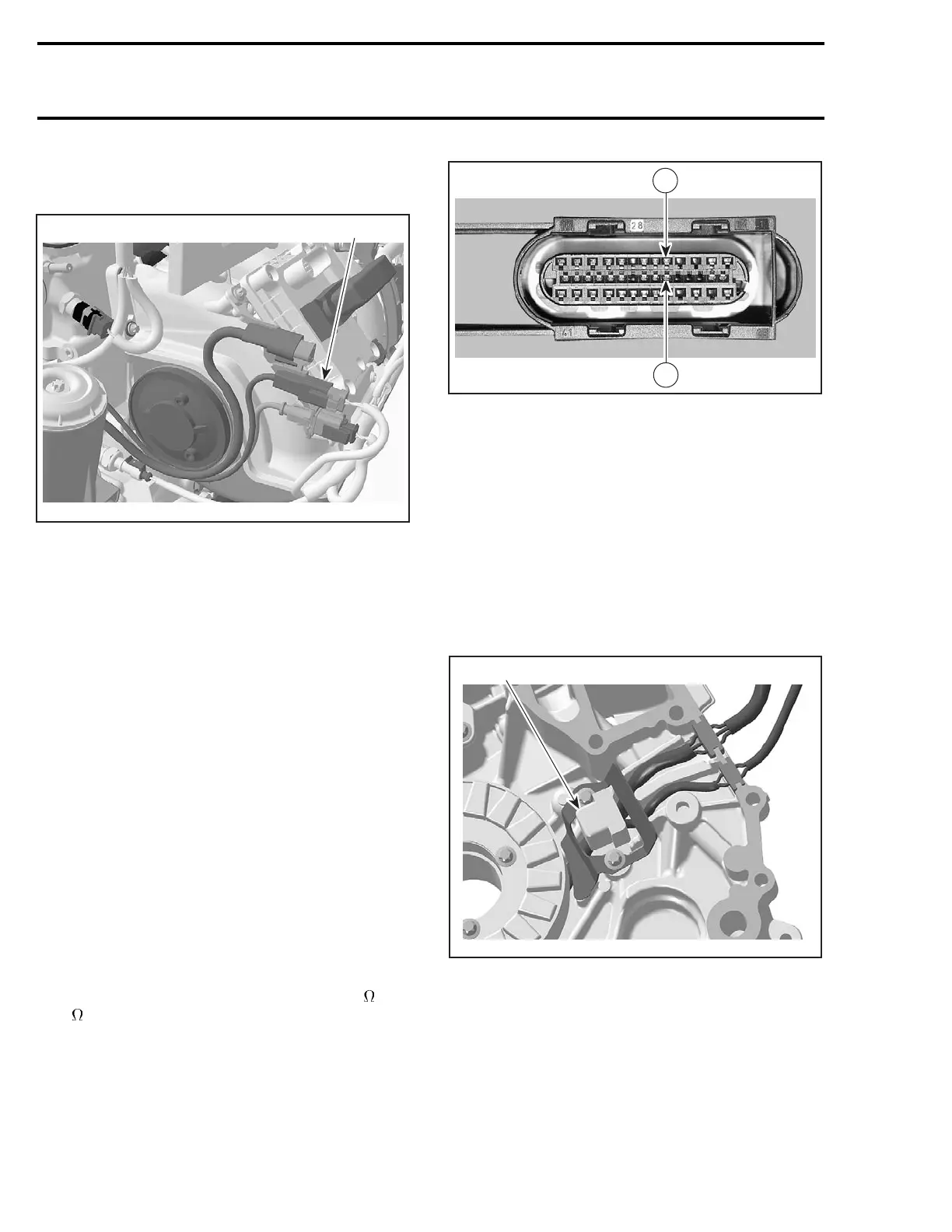

1

R1503motr169A

TYPICAL

1. CPS connector

Ensure that information center works. Needles

will sweep, LED and LCD segments will turn on

when the safety lanyard is installed. Check for

RPM display at the information center while crank-

inginenginedrownedmode. PressandHOLD

throttle lever then press start/stop button. 800-

1000 RPM should display. Otherwise perform the

following tests.

NOTE: Take into account that a CPS fault can be

triggered by bent or missing encoder wheel teeth.

First check fault codes then check the teeth con-

dition if necessary. See below.

Disconnect CPS wiring harness connector. Probe

terminals coming from CPS while cranking engine.

Voltage should be within 1-2 Vac. Otherwise, in-

spect wiring and replace CPS if wiring is good.

Resistance Test

Disconnect the CPS connector from the wiring

harness and check the resistance of the sensor

itself.

The resistance should be between 190

and

290

.

Otherwise, replace the CPS.

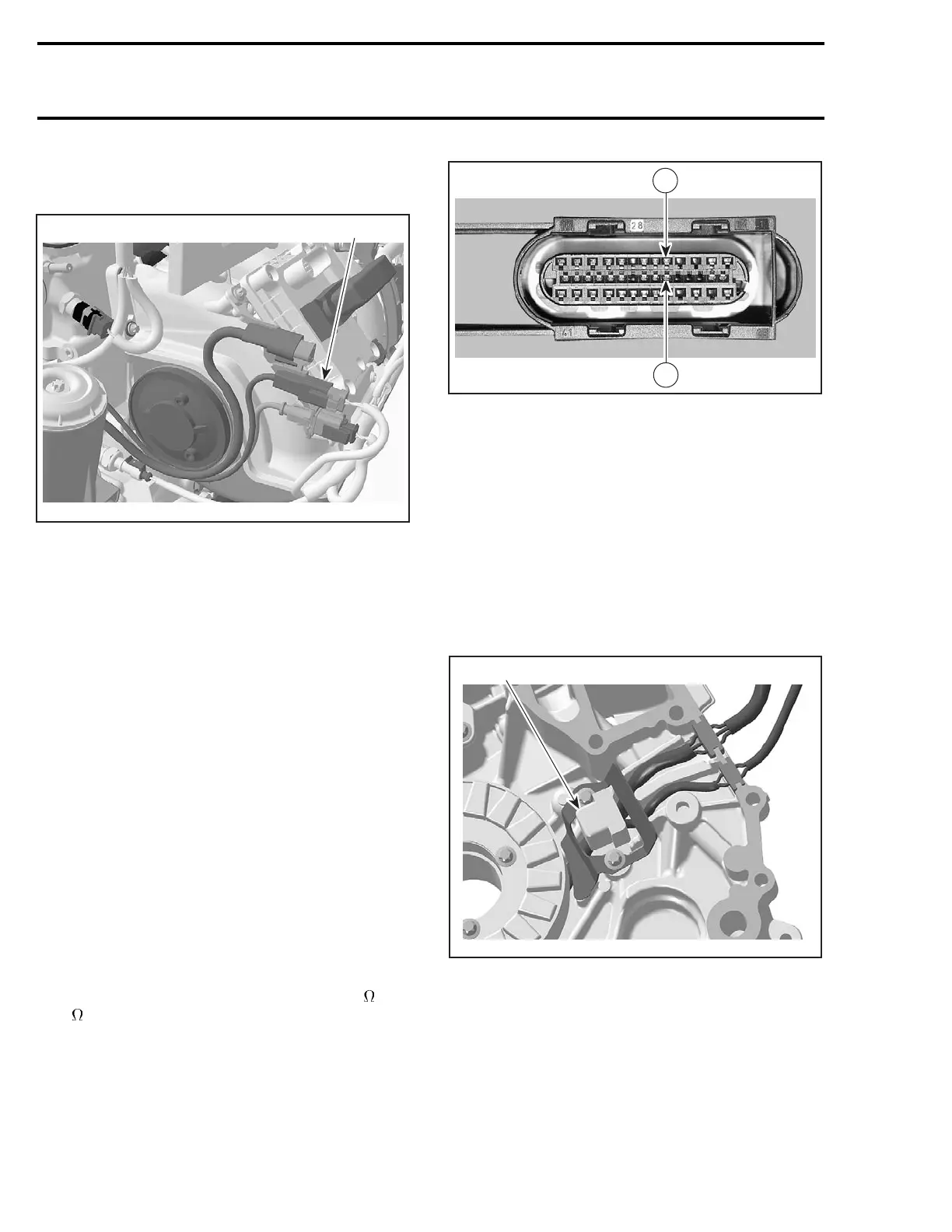

If resistance tests good, reconnect the CPS and

disconnect the ECM connector A on the ECM.

Using a multimeter, recheck resistance value be-

tween terminals 5 and 19.

R1503motr182A

5

19

If resistance value is correct, try a new ECM. Refer

to ECM REPLACEMENT procedures elsewhere in

this section.

If resistance value is incorrect, repair the connec-

tors or replace the wiring harness between ECM

connector and the CPS.

Replacement

Disconnect connectors and remove the PTO

cover. Refer to PTO HOUSING/MAGNETO in

ENGINE section.

Remove CPS.

1

R1503motr170A

1. CPS inside PTO cover

Apply Loctite 243 on screw threads then install the

new CPS. Torque to 10 N•m(89lbf•in).

Reinstall remaining removed parts.

Encoder Wheel Inspection

To check the encoder wheel for bent teeth, pro-

ceed as follows.

424 smr2004-Complete Line Up

Loading...

Loading...