Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

CAUTION: Failure to properly clean the oil sys-

tem will result in serious engine damage.

The inspection of top end should include the fol-

lowing measurements.

TOLERANCES

ENGINE

MEASUREMENT

NEW PARTS

(min.) (max.)

WEAR

LIMIT

Piston/cylinder

wall clearance

0.12 mm

(.005 in)

N.A.

0.2 mm

(.008 in)

Ring end gap

0.1 mm

(.004 in)

0.25 mm

(.010 in)

0.5 mm

(.020 in)

N.A.: NOT APPLICABLE

Piston/Cylinder Wall Clearance

Clearance can be quickly checked with a feeler

gauge. Insert feeler gauge in cylinder then slide

piston (without piston rings installed). If clearance

exceeds tolerance, check cylinder top area with

your finger to feel if there is a ridge. If so, the

cylinder sleeve is worn and needs replacement.

Otherwise, replace piston.

Ring End Gap

Position ring close to top of cylinder top.

NOTE: In order to correctly position ring in cylin-

der, use piston as a pusher.

Using a feeler gauge, check ring end gap. If gap

exceeds specified tolerance, rings should be re-

placed.

21

F12R07A

1. Top of cylinder

2. Ring end gap

Assembly

Apply injection oil in cylinder and on rings prior to

installing.

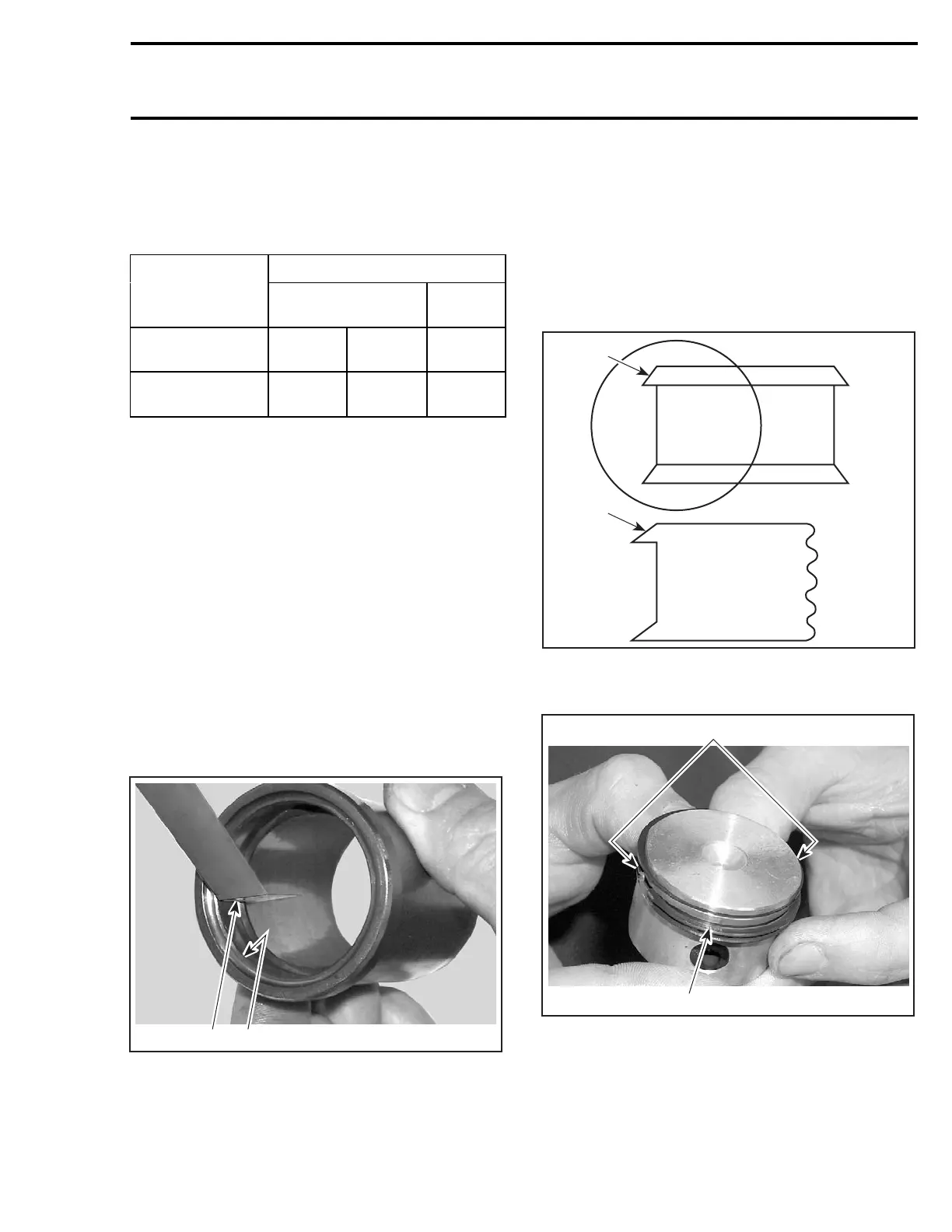

Install the oil ring with the “TOP” markingontop.

Identify the correct position by looking at beveled

edge of oil ring and while installation, make sure

that the beveled edge is towards the top of the

piston.

1

F12R1OA

1

1. Beveled edge

Position ring openings 180° apart.

2

F12R15A

1

1. Ring openings 180° apart

2. TOP marking on this side

Use ring compressor (P/N 529 035 713) and insert

piston in cylinder.

NOTE: Cylinder may be removed from crankcase

to install piston more easily from the bottom.

smr2004-Complete Line Up 345

Loading...

Loading...