Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

2

3

1

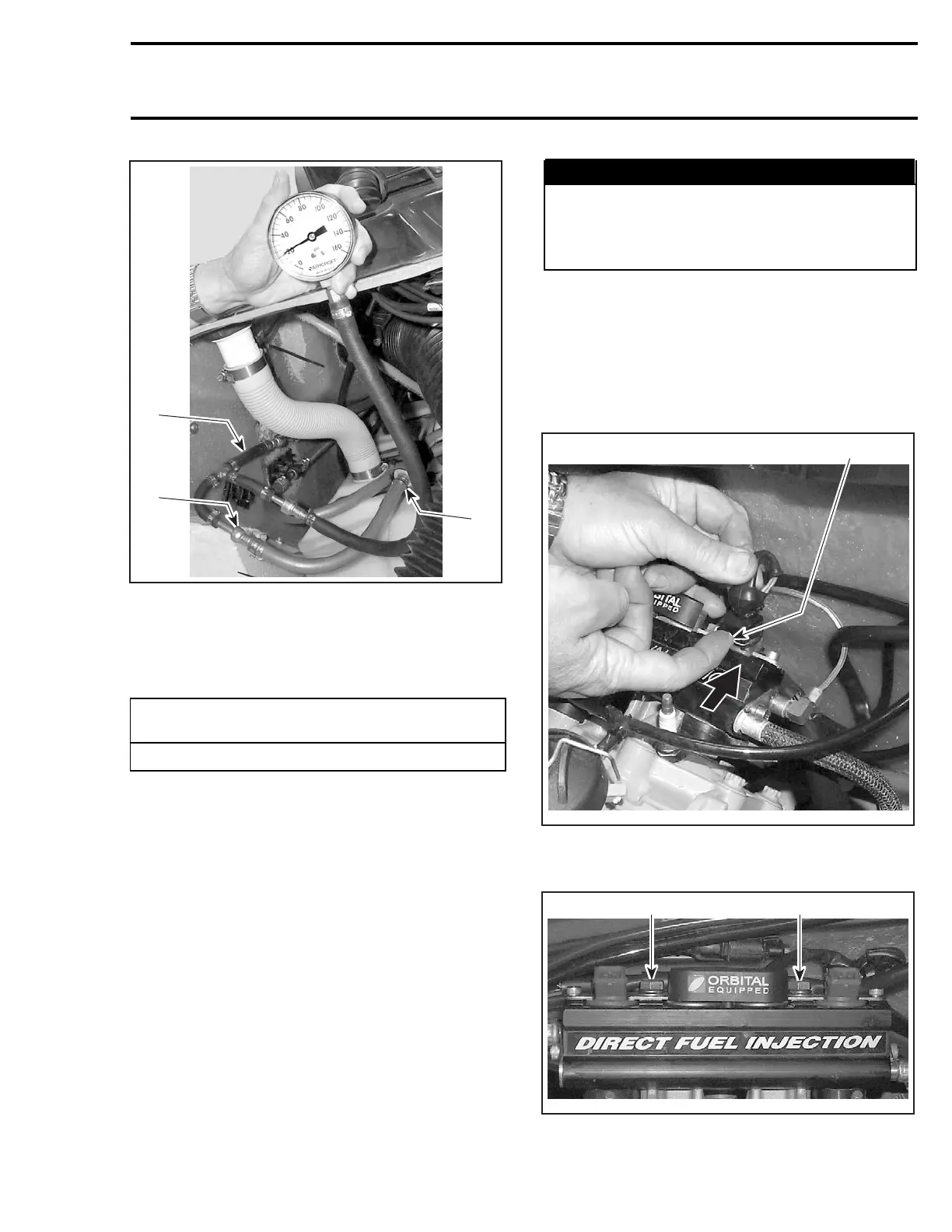

F12R09A

1. Fuel filter

2. Fuel line going to air/fuel rail

3. Pressure gauge between disconnected ends (

in-line installation)

Install safety lanyard and observe fuel pressure.

Do not crank engine.

FUEL REGULATOR PRESSURE

(when installing safety lanyard)

185±14kPa(27±2PSI)

If pressure is good, fuel pressure regulator is

working adequately.

A rapid pressure drop indicates leakage either

from the air/fuel rail or the fuel pump check valve.

Check air/fuel rail for leaks. If it occurs while

installing safety lanyard on DESS and air/fuel rail

is not leaking, then replace fuel pump.

A slow pressure drop indicates leakage either

from the fuel injector or from the fuel pressure

regulator. Check fuel injector for leaks (see be-

low). If it is not leaking then replace fuel pressure

regulator.

NOTE: Fuel in air compressor outlet line is an in-

dication of a leaking fuel pressure regulator di-

aphragm.

Remove pressure gauge and reinstall fuel hose.

At installation apply engine oil on O-ring.

WARNING

Wipe off any fuel spillage in the bilge. Fu-

el is flammable and explosive under certain

conditions. Always work in a well ventilated

area.

Fuel Pressure Regulator Replacement

Removal

Release the fuel pressure in the system.

Disconnect spark plug cables from spark plugs.

Disconnect the fuel injector wires, if necessary.

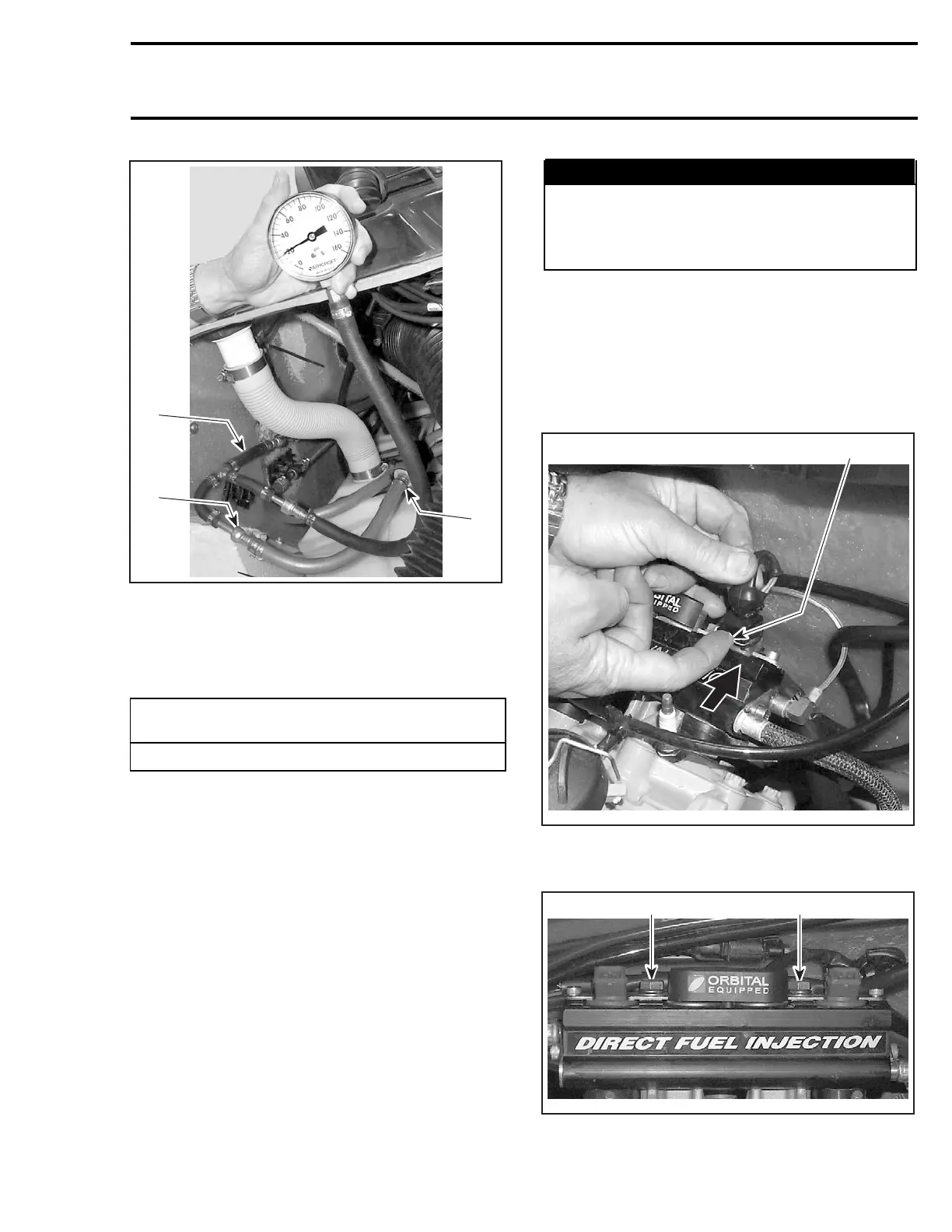

1

F12R0DA

1. Push clip toward injector to release connector

Unscrew rail retaining screws.

F12R19A

1

1

1. Retaining screws

smr2004-Complete Line Up 347

Loading...

Loading...