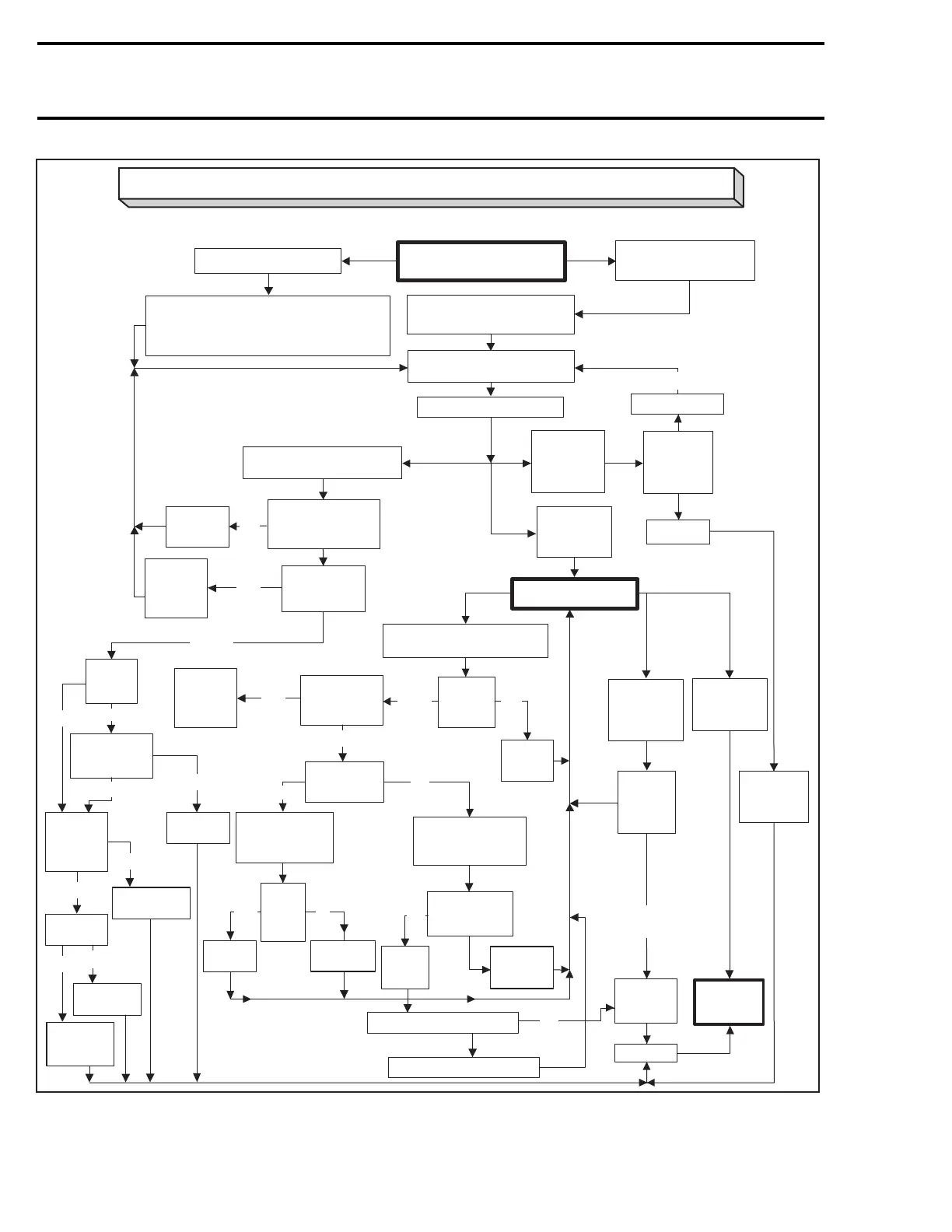

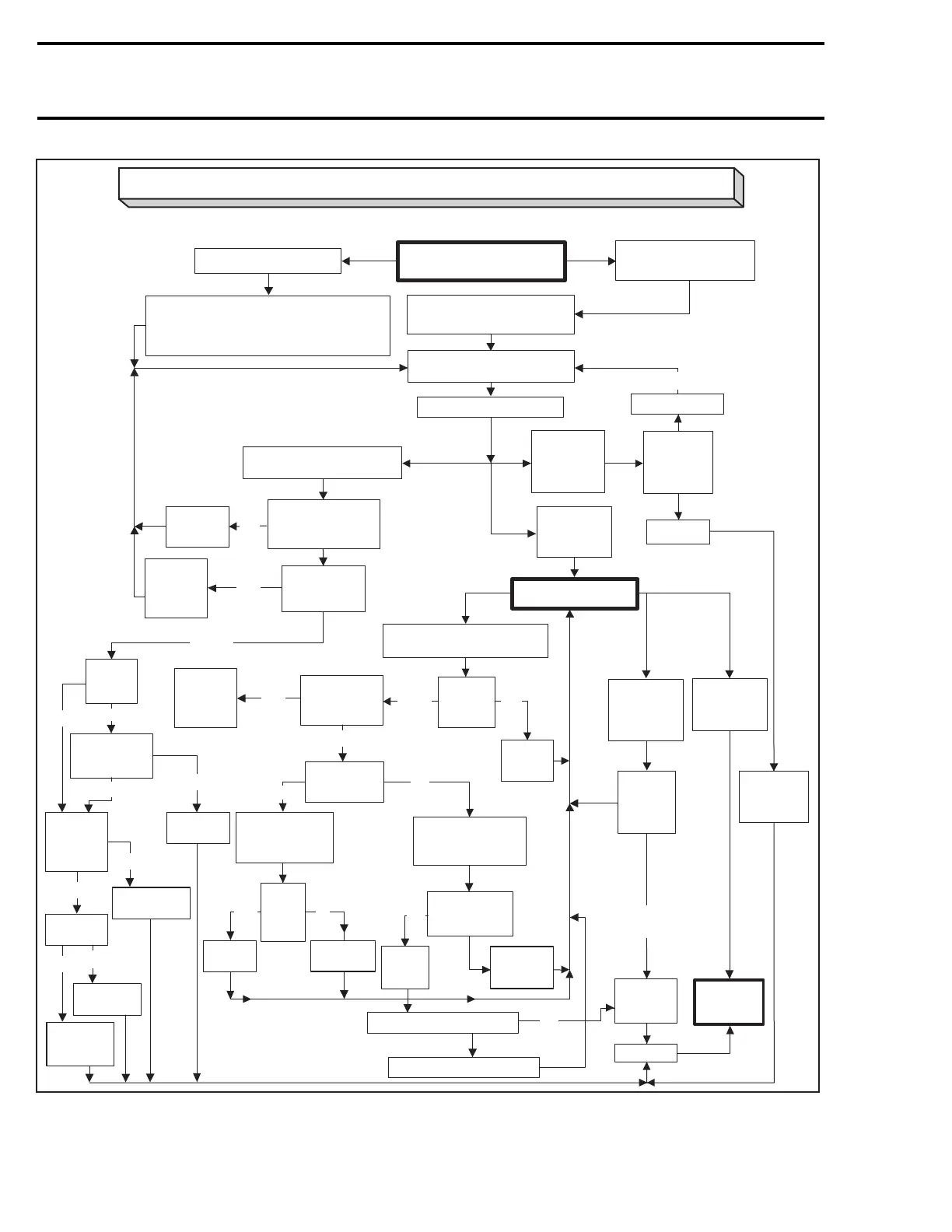

Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

OK

no

F12A06S

Air pressure less

than 621 kPa

(90 PSI)

FUEL DELIVERY SYSTEM DIAGNOSTIC FLOW CHART

line

OK

Crank or start engine

Install pressure gauge on

fuel pressure line

Connect safety lanyard

Fuel pump runs

Fuel pressure less

than 185 kPa (27 PSI)

Fuel pressure

more than

185 kPa

(27 PSI)

Fuel pressure

is 185 kPa

(27 PSI)

System OK

Check fuel lines

for leaks

Check fuel filters

Repair or

replace

Perform fuel

pump test

Proceed to air

compressor

pressure test

Fuel pressure lower

than 735 kPa (107 PSI)

Check for

blocked fuel

return line

Repair or replace

Line OK

yes

Replace

fuel pump

module

Fuel pressure

is 735 kPa

(107 PSI)

Fuel pressure

greater than

735 kPa

(107 PSI)

Check air

return

line for

blockage

Check

for air

leaks

Repair

leaks

Check direct

injector

yes

Perform fuel

pump test

Replace

fuel pump

module

pass

no

leaks

Check

RAVE

for air

leaks

Repair air

compressor

Air pressure more

than 621 kPa

(90 PSI)

OK

Replace

direct

injector

Connect safety lanyardFuel pump does not run

Fuel pump runs

for 2 sec. then stops

Check fuses

Check lanyard connection

Check pump module operation

Repair or replace if necessary

test OK

OK

fails

Replace fuel

pressure

regulator

Replace air

pressure

regulator

Retest

Direct

injector

OK

Check air/fuel rail for leaks

Repair/replace air/fuel rail

OK

fails

fails

no

leaks

fails

Repair

leaks

Fast

pressure

drop

yes

no

Verify

fuel pump

check valve

fails

Replace

fuel pump

OK

Ensure

air/fuel

rail is not

leaking

yes

Check fuel

injector

Repair/replace

air/fuel rail

OK

fails

Replace fuel

injector

Replace fuel

pressure

regulator

fails

NOTE:

The tolerance for the pressure is ± 14 kPa (2 PSI).

356 smr2004-Complete Line Up

Loading...

Loading...