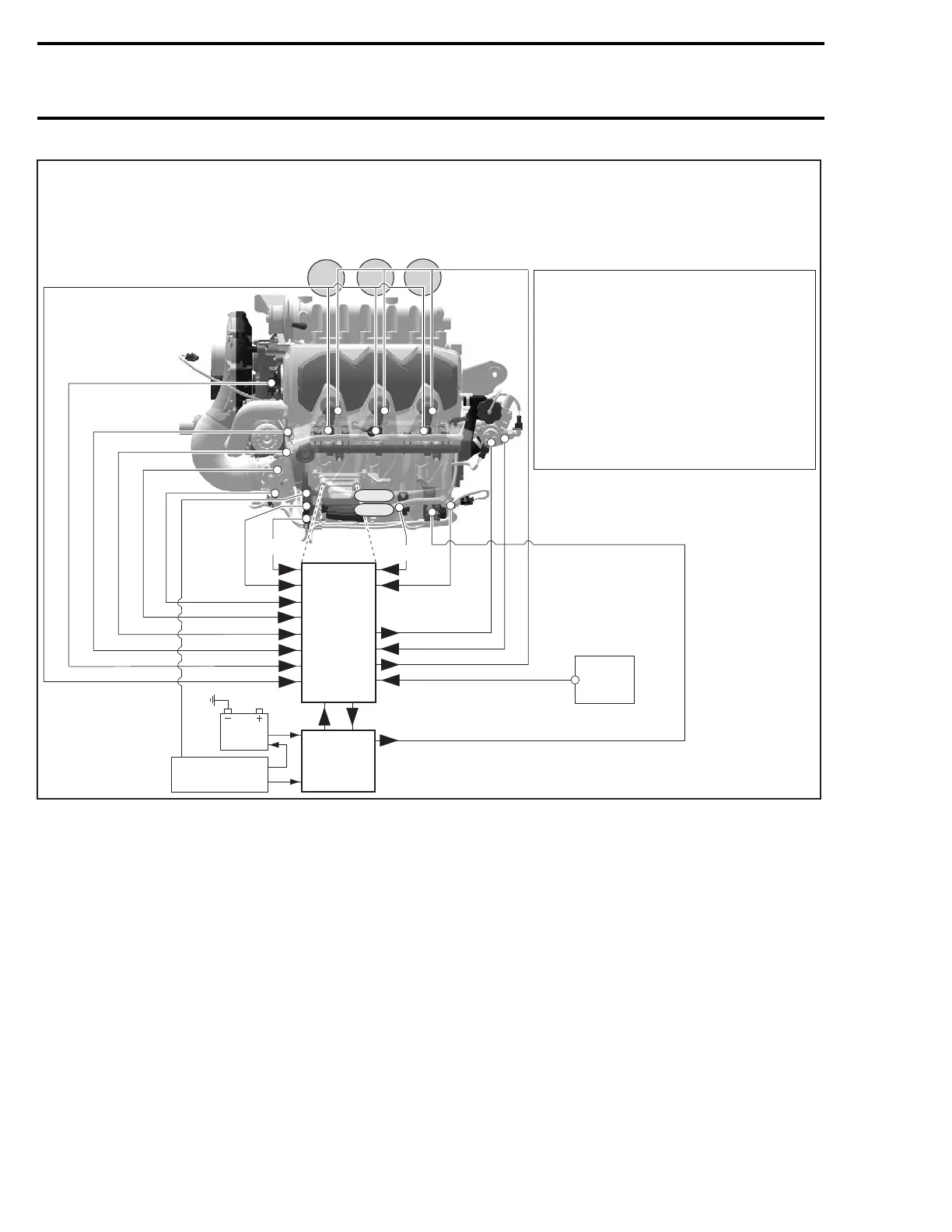

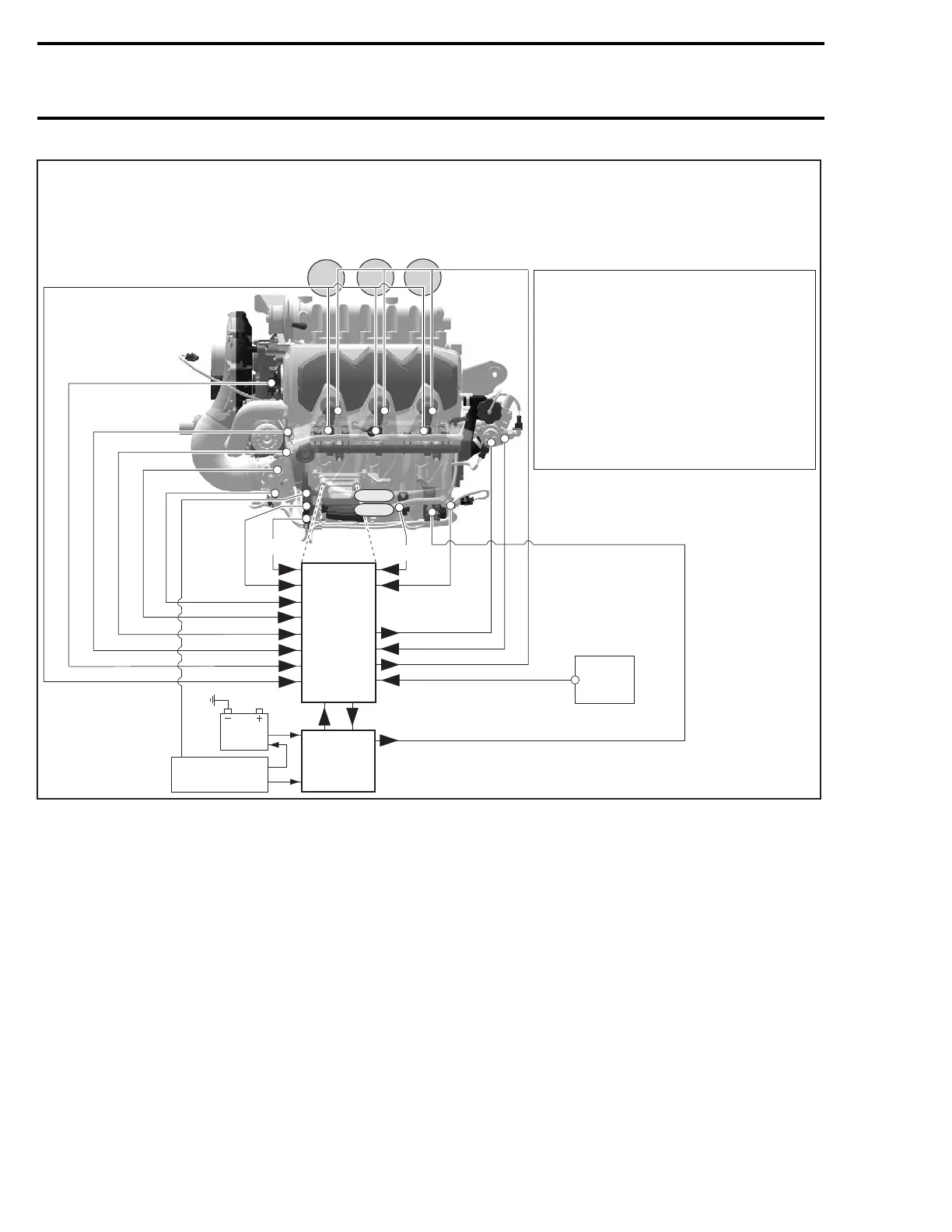

Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 01 (OVERVIEW)

R1503motr266T

ENGINE MANAGEMENT SYSTEM - OVERVIEW

ROTAX 1503 4-TEC SUPERCHARGED

ECM

KS

CPS

OPS

CTS

CAPS

INJECTOR 1,2,3

MAPS

MATS

IDLE

BYPASS VALVE

TPS

IGNITION COIL

OSPS

TOPS VALVE

EGTS

MPEM

REGULATOR/

RECTIFIER

MUFFLER

Cyl.1 Cyl.2 Cyl.3

MAGNETO

ENGINE POWER SUPPLY

ECM ECM Engine Control Module

MPEM Multi-Purpose Electronic Module

KS Knock Sensor

CPS Cranshaft Position Sensor

OPS Oil Pressure Sensor

OSPS Oil Separator Pressure Sensor

CTS Coolant Temperature Sensor

CAPS Camshaft Position Sensor

EGTS Exhaust Gas Temperature Sensor

MAPS Manifold Air Pressure Sensor

MATS Manifold Air Temperature Sensor

TOPS Tip-Over Protection System

Con.A Connector for Engine Wiring Harness

Con.B Connector for MPEM Connection

BATTERY

Con. A

Con. B

The complete electrical system is managed by

micro-controllers working together. Overall, the

MPEM (multi-purpose electronic module) man-

ages the vehicle electrical system, the EMS

(engine management system) controls the en-

gine management and the information center is

used to display information that comes both from

MPEM and EMS.

A communication link is used between the elec-

tronic modules to communicate with each other.

It consists of a twisted pair of wires (WHITE/RED

and WHITE/BLACK).

For communication link troubleshooting, refer to

INSTRUMENTS AND ACCESSORIES in ELECTRI-

CAL section.

Thecommunicationlinkisalsousedtocommuni-

cate informative messages, monitoring and diag-

nostic codes to the information center and to the

VCK (vehicle communication kit) where B.U.D.S.

(Bombardier utility and diagnostic system) is used

for diagnosing and troubleshooting the system.

The fault code can be seen from either the infor-

mation center or B.U.D.S. Refer to DIAGNOSTIC

PROCEDURES section.

392 smr2004-Complete Line Up

Loading...

Loading...