Section12ELECTRICALSYSTEM

Subsection 01 (IGNITION SYSTEM)

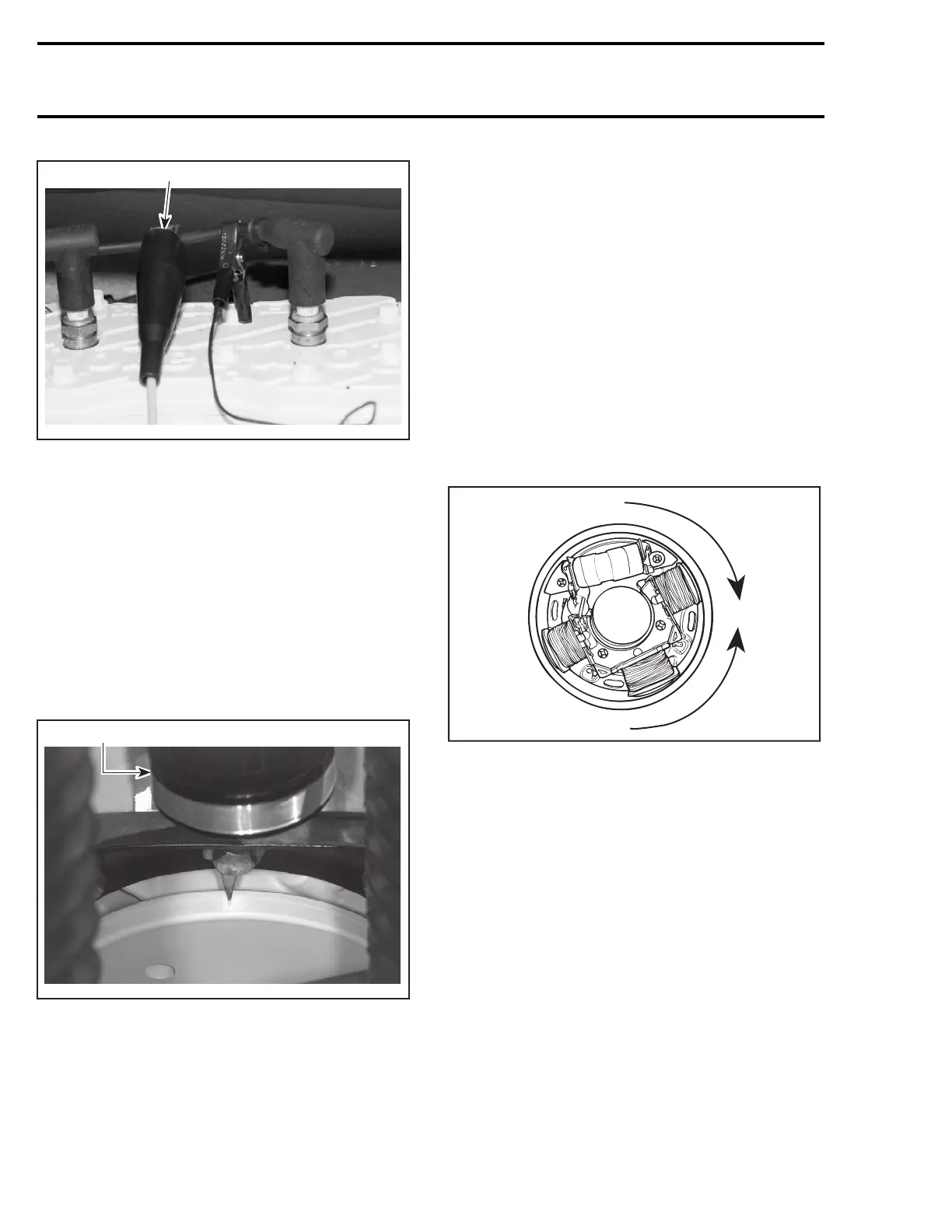

F00H0HA

1

1. Timing light pick-up

IMPORTANT: To check the ignition timing, the

timing advance curve must be locked first. This

allows to perform ignition timing at any RPM by

keeping the timing “frozen” so that it does not

vary with engine RPM. See FIXED TIMING FUNC-

TION for more information.

NOTE: Fixed Timing function must be activated

before starting engine when using the MPEM pro-

grammer. When using B.U.D.S., it must be acti-

vated after starting the engine.

– Start engine and point the beam of a timing light

on mark.

F06H07A

1

1. Timing light straight in line with tool slot

CAUTION: If engine is to be run more than a

few seconds, engine must be cooled using the

flush kit.

NOTE: If mark on PTO flywheel is perfectly

aligned with timing mark pointer, no adjustment

is required. If mark does not align with pointer,

recheck PTO flywheel mark before adjusting igni-

tion timing to ensure PTO flywheel has not loosen

or moved.

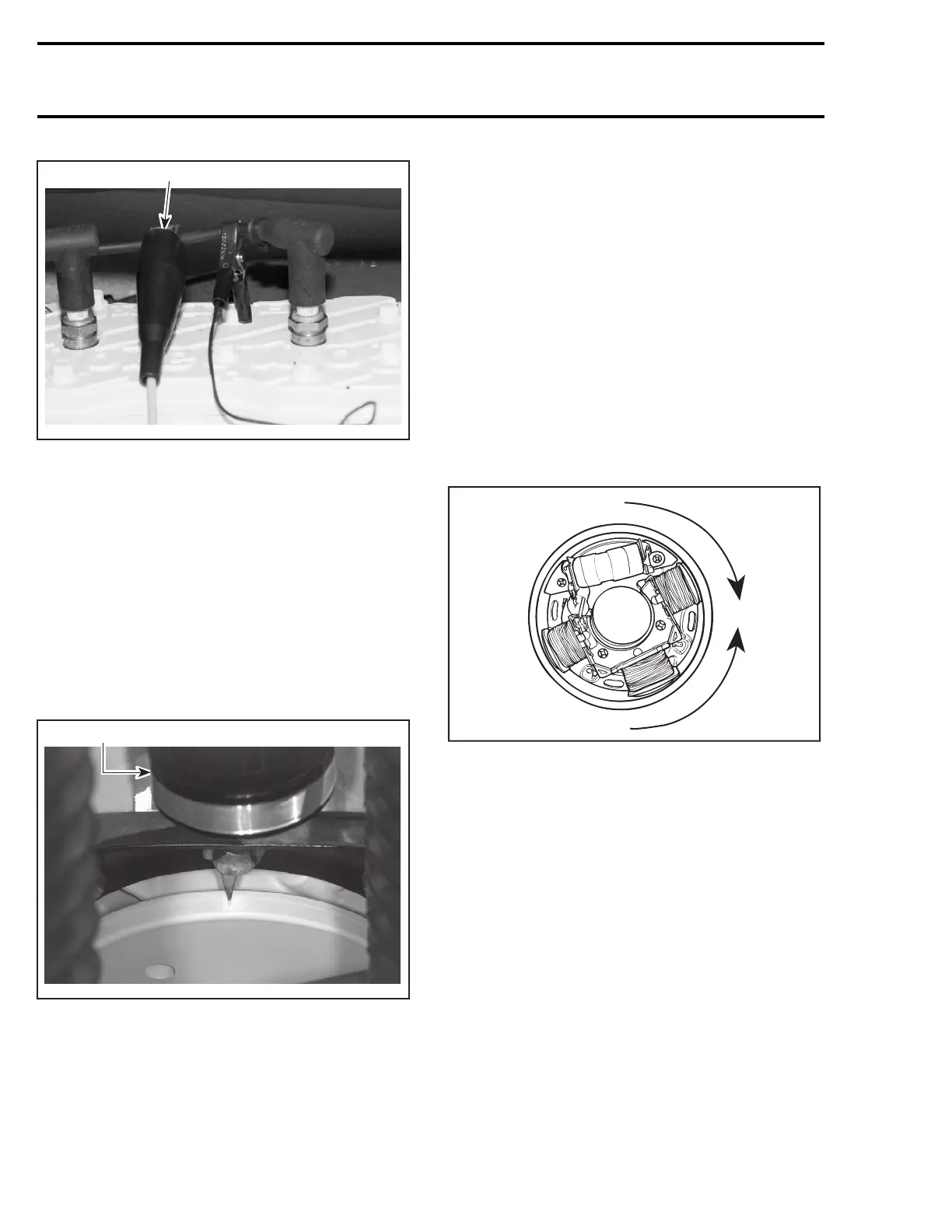

Ignition Timing Adjustment

717 Engines

Remove magneto housing cover and wire sup-

port.

For removal of magneto, refer to MAGNETO SYS-

TEM.

Timing is performed by moving armature plate;

clockwise to retard spark occurrence or counter-

clockwise to advance.

A25E0RA

1

2

TYPICAL

1. To retard

2. To advance

To adjust, loosen 3 armature plate retaining

screws and slightly rotate armature plate in prop-

er direction.

NOTE: As a guideline, turn the armature plate the

same amount needed to align mark on PTO fly-

wheel.

548 smr2004-Complete Line Up

Loading...

Loading...