144

Manual – MOVIDRIVE® MDX61B Safety Module MOVISAFE® DCS..B Option

12

Typical response times

Appendix

12.6 Typical response times

12.6.1 Typical response times of the DCS21B option

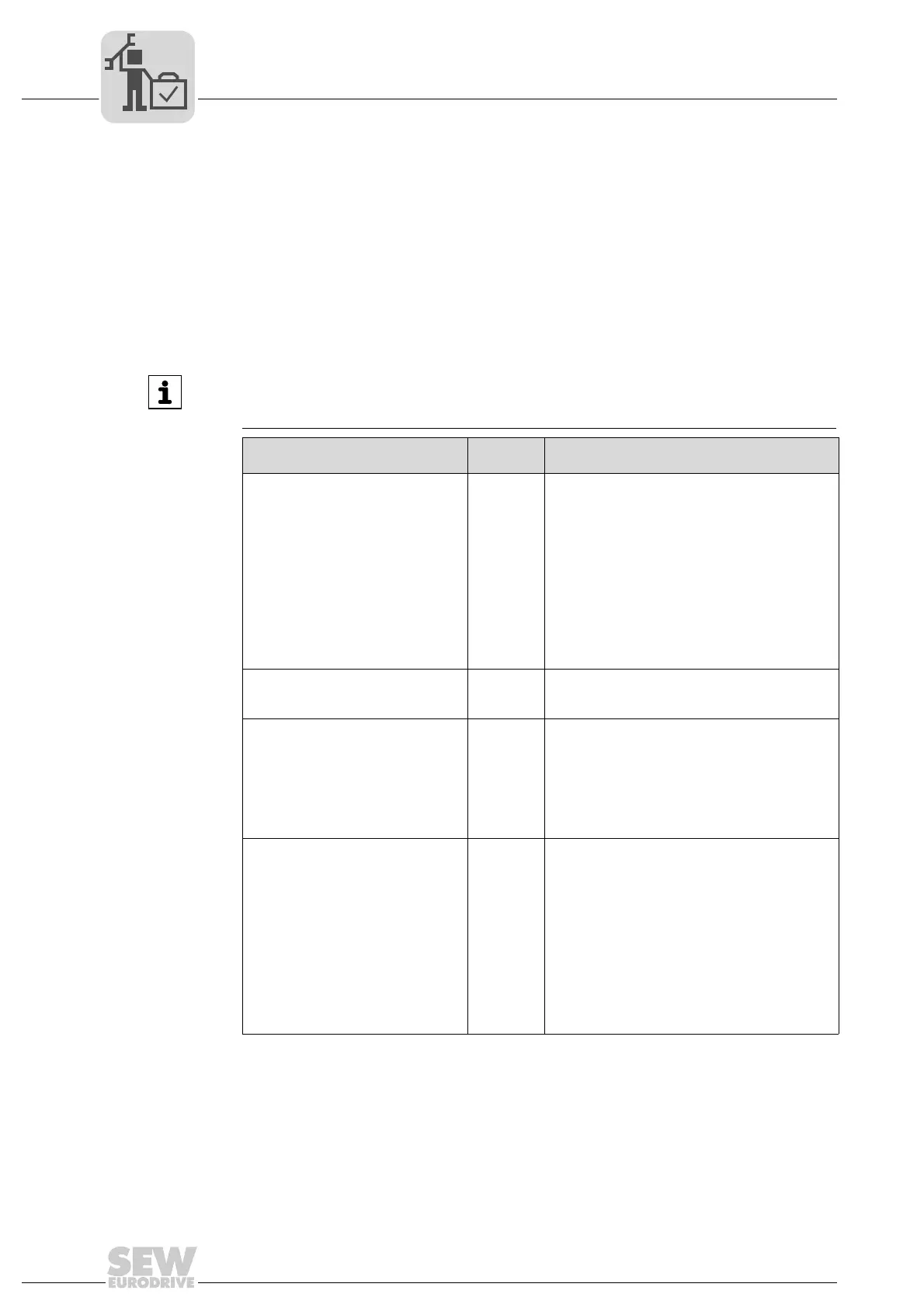

The following table lists the response times of the DCS21B options.

For the PROFIsafe application, the cycle time (T_cycle) is 28 ms. The specified

response times correspond to the maximum runtime for the specific application within

the DCS21B option. For bus applications, the processing time for safety control and,

depending on the application, additional, application-specific response times for sensors

and actuators, must be added to calculate the total run time. For calculating the runtime

in the safety control, refer to the technical documentation of the manufacturer.

INFORMATION

If the "overspeed distance monitoring" filter is used, the response time will increase

depending on the set distance.

Function Response

time [ms]

Explanation

PROFIsafe bus timeout

(minimum timeout interval)

125 The minimum timeout interval for the bus is

125 ms. If a general bus error is assumed (e.g.

corrupt data, interrupted communication), all

outputs of the DCS21B option are disabled once

the specified time has elapsed. The same applies

to the connection from the DCS21B to the safety

controller.

Note: The timeout interval of the bus system

can be scaled to any higher value in the safety

controller (e.g. S7) under "HW Config". The

timeout interval must be used for calculating

the response time of the DCS21B option.

Reading-in a digital NC contact and

transfer to the safety controller via

PROFIsafe.

84 The DCS21B recognizes the opening of a live

contact within one cycle. Two more cycles are

required for transmission to the safe bus system.

Reading-in a digital NO contact and

transfer to the safety controller via

PROFIsafe.

112 For a NO contact to be recognized as active ("1"),

an active signal level must be present at the input

for an entire clock cycle of the DCS21B option. In

the worst case, sampling will take two cycles to

make relevant information available for internal

processing. Two more cycles are required for

transfer to the bus; this means the total number of

cycles is 4.

Response of an already activated

monitoring function using local

disconnection for position and speed

processing

• Observe the note at the end of this

table

56 For a monitoring function that has already been

activated via PROFIsafe, the DCS21B option

needs one cycle to calculate the current speed

value. During the next cycle, the result is entered in

the system image once the monitoring function was

calculated. If local disconnection has been

activated (available in the DCS21B option), a

programmed output is operated within the same

cycle, if required.

Note: When using local disconnection and

ENABLE via the bus system, the specified time

is the relevant response time.

Loading...

Loading...