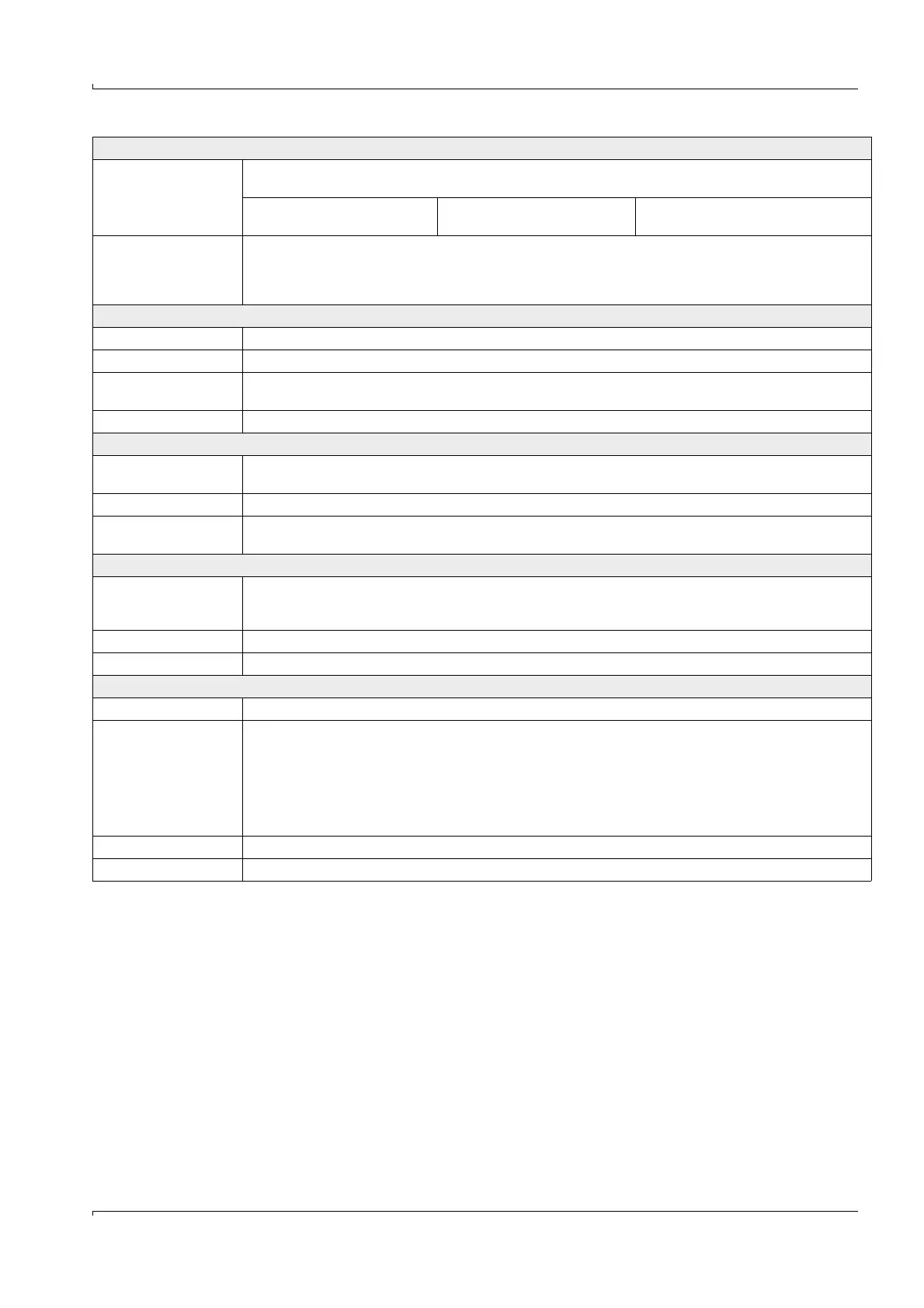

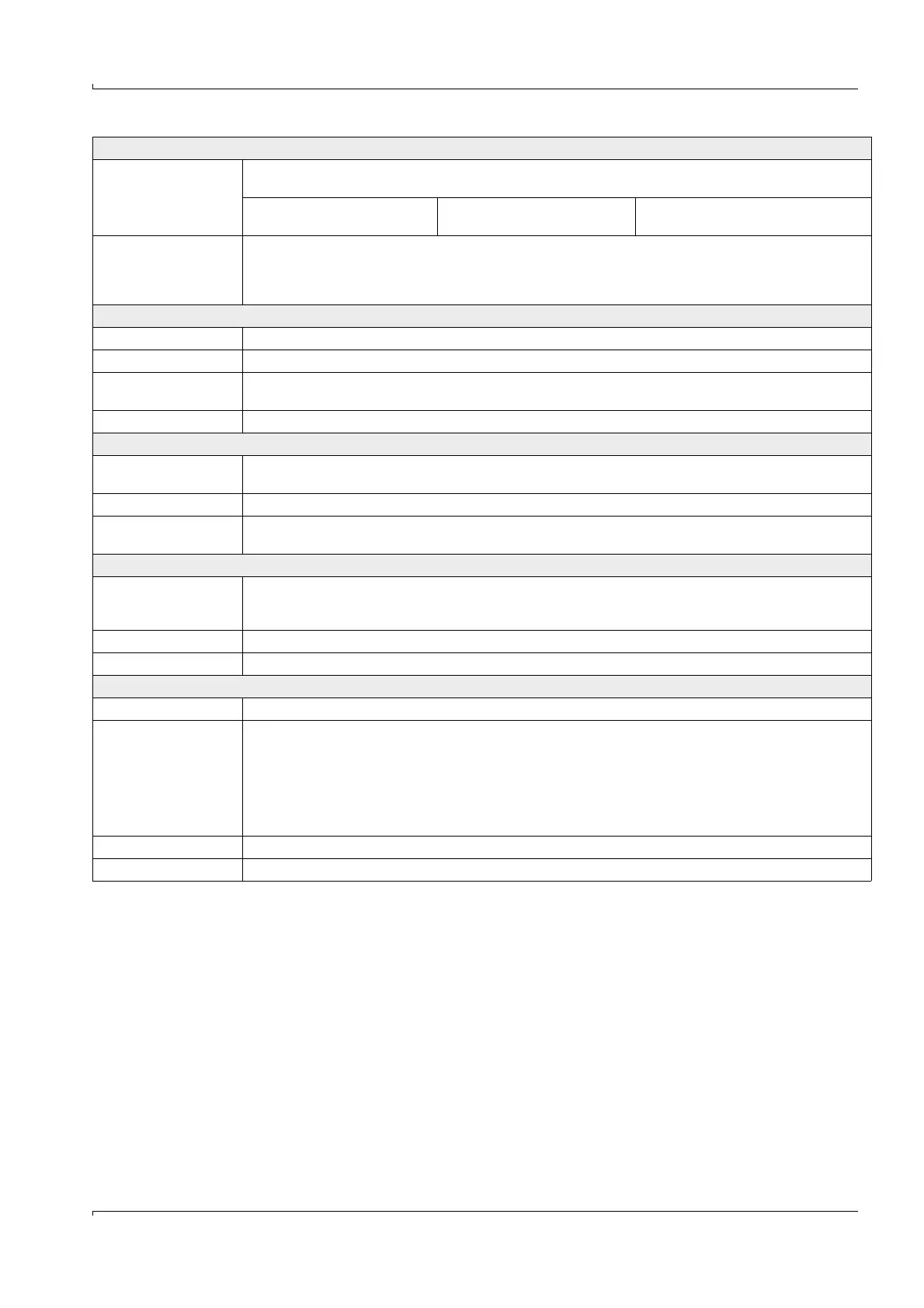

Specifications

FLOWSIC100 Flare · Operating Instructions · 8013344/11L2/V 2-5/2018-10 · © SICK Engineering GmbH 211

Subject to change without notice

1

)

: Depending on process conditions

2)

: For fully developed flow profile

3)

:Hydrocarbons

4)

: Dry calibrated

5)

: Flow calibrated, valid at range > 1 m/s ... 120 m/s for types FLOWSIC100 EX-S/EX/EX-RE; > 1 m/s ... 90 m/s for type

FLOWSIC100 EX-PR

6)

: Maximum pipe diameter depending on gas composition

7)

: Preferred operating range for nominal pipe diameter ≥ 24", smaller diameters at difficult gas compositions with sound-

absorbing components

8)

: Operating temperature range of ball valve:

standard: -50... +200 °C

high temperature: -50 ... +350 °C

low temperature: - 196 ... +100 °C

Housing version, degree of protection

Sender/receiver units ● For use in zone 1: Flameproof enclosure made of aluminium or stainless steel (option), IP 65/67

12)

● For use in zone 2: Housing made of aluminium, IP 65

● CSA: enclosure type 4, IP65 ● CSA: enclosure type 6, IP 65/

67 single seal

● CSA: enclosure type 4, IP 65

MCUP ● For use in zone 1: Flameproof enclosure made of aluminum, IP 66

● For use in zone 2, Div2: Wall housing made of steel, IP 66, enclosure type 4 (optionally 4X)

● For use in Div 1: Flameproof enclosure made of aluminum, IP 66, enclosure type 4 (optionally 4X),

● For use in the safe area: Wall housing made of steel, IP 66 and 19” rack made of aluminium, IP 20

Inputs, outputs, controls via MCUP control unit

Analog output 1 output active: 0/2/4 ... 22 mA, max. load 500 Ω, according to NAMUR NE43

Analog inputs 2 inputs: 0 ... 5/10 V or 0 ... 20 mA

Digital outputs Pulse/frequency output (opt. module); 5 outputs: : 48 V d.c./1A, 30 V d.c./1A (MCUP zone 2); floating

status signals: operation/malfunction, maintenance, check cycle, limit value, maint. request

Digital inputs 2 inputs for connection of floating contacts

13)

Communication interfaces

USB 1.1, RS232 (on

terminals) For measured value inquiries and software updates per PC/laptop using the operation program

RS485 To connect the sender/receiver units

Interface modules Pulse, Ethernet + pulse, Ethernet triplex + pulse, MODBUS TCP + pulse, MODBUS RS485 + pulse, HARTBUS AO

+ pulse, PROFIBUS RS485 + pulse, Foundation Fieldbus + pulse

Power supply

Operating voltage ● MCUP non-EX, ATEX zone 1: 100 … 240 V a.c., 50/60 Hz, optional 24 V d.c.

● MCUP ATEX zone 2, CSA Cl I, Div 2: 115/230 V a.c. automatically controlled, optional 24 V d.c.

● MCUP CSA Cl I, Div 1: 100 … 240 V a.c., 50/60 Hz, optional 24 V d.c.

Power input Approx. 20 W for all types

Fuse protection Fuse T 2 A, slow blow, sand-filled

14)

Weight

Sender/receiver units Depending on the version, max. approx. 35 kg

MCUP

● Zone 1 housing size 4:

● Zone 1 housing size 6:

● Zone 1 housing stainless steel:

● Zone 2 and version without explosion protection:

● 19” rack:

● CSA Cl I, Div 1 housing size 4:

● CSA Cl I, Div 1 housing size 6:

Approx. 14kg

Approx. 18kg

Approx. 70kg

Approx. 5 kg

Approx. 6 kg

Approx. 12kg

Approx. 16kg

Nozzle ANSI Cl150 2” CS: approx..3,5 kg ANSI CL150 3” CS: approx.. 8 kg

Ball valve ANSI CL150 2”: approx..6,1 kg ANSI CL150 3”: approx..12 kg

Loading...

Loading...