4)

Voltage between A1 of the main module and ENCx_24V at 0.2A sum load current.

5)

Voltage between ENCx_y+ and ENCx_y–.

6)

Voltage between ENCx_y+ and ENC_0V and between ENCx_y– and ENC_0V.

7)

Voltage between ENCx_y+ and ENCx_y– with a terminating resistance of ≥60Ω.

8)

Plus the resolution of the speed information based on the resolution of the encoder system:

a)

Rotational movement in rpm = 15,000/(4 × number of A/B periods per revolution)

b) Linear movement in mm/s = 250/(4 × number of A/B periods per revolution)

9)

Plus the resolution of the position information based on the resolution of the encoder system:

1rev./(4×number of A/B periods per revolution).

10)

Peak to peak voltage between ENCx_y+ and ENCx_y–.

11)

Voltage between ENCx_y+ and ENC_0V and between ENCx_y– and ENC_0V.

12)

You can find a description of this function in the “Flexi Soft in the Flexi Soft Designer Configuration

Software” or “Flexi Soft in the Safety Designer Configuration Software” operating instructions in the

“Sine-cosine analog voltage monitoring” section.

13)

Plus the resolution of the speed information based on the resolution of the encoder system:

a) Rotational movement in rpm = 15,000/(4×number of sine-cosine periods per revolution)

b) Linear movement in mm/s = 250/(4 × number of sine-cosine periods per revolution)

14)

Plus the resolution of the position information based on the resolution of the encoder system:

1rev./(4×number of sine-cosine periods per revolution).

15)

Master mode and listener mode.

16)

These are parameters of the SSI encoder that can be set using the configuration software.

17)

Time between the falling edges of the clock.

18)

Without start bit. If repeat transmission is being used (clock continues without gap in order to transmit

the same data again), the entire stream is considered as one frame.

19)

If the maximum permissible change to the position information (speed)is exceeded, then this can lead

to the output of an inverted rotation direction and to a lower speed, since it results in non-recognized

overflowing of the position data bits.

20)

Plus the resolution of the speed information based on the resolution of the encoder system:

a) Rotational movement in rpm = 15,000/(increments per revolution)

b) Linear movement in mm/s = 250/(increments per revolution)

21)

Plus the resolution of the position information based on the resolution of the encoder system:

1rev./(increments per revolution).

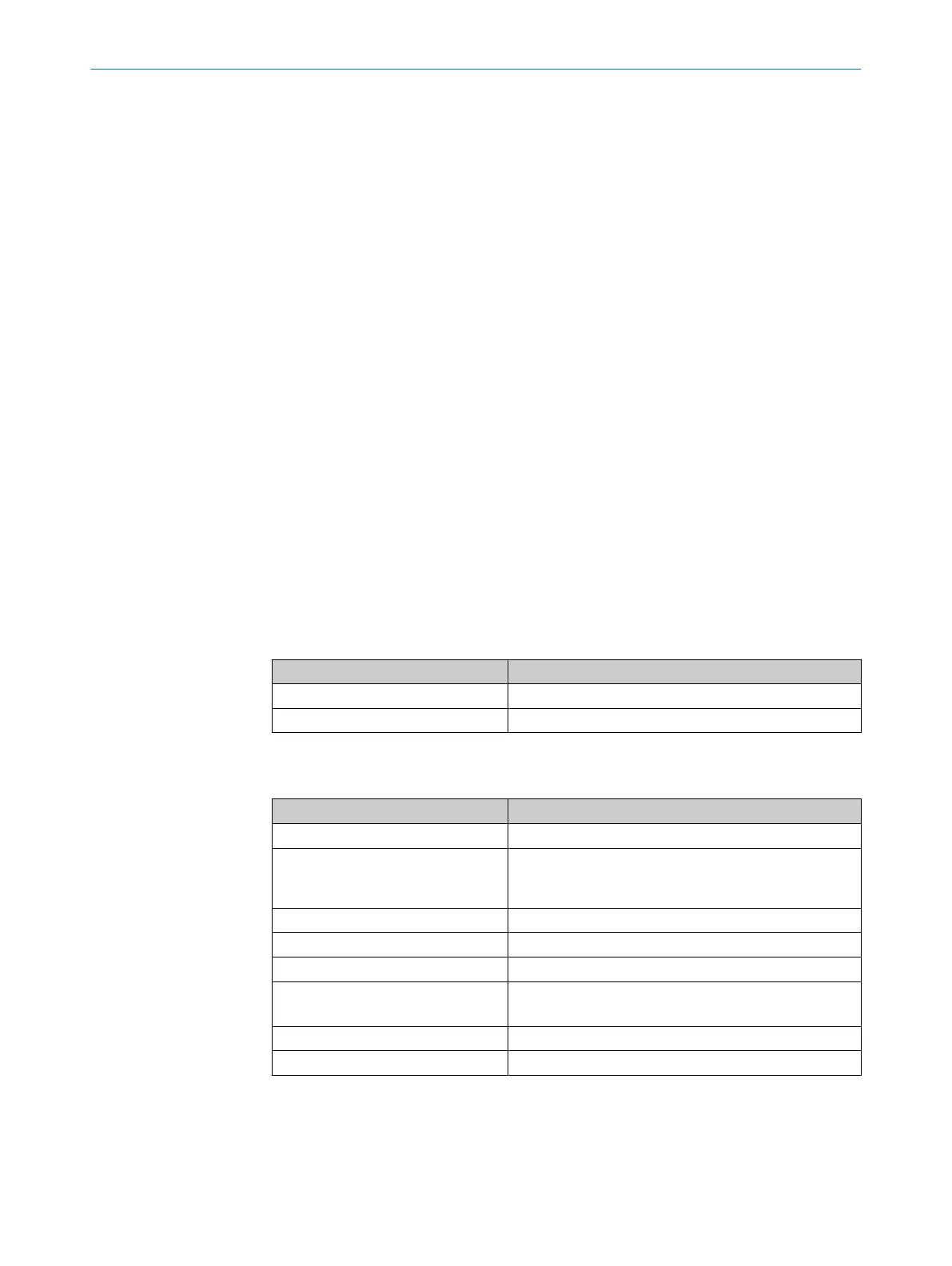

Mechanical data

T

able 173: Mechanical data MOC1

MOC1

Dimensions (W × H × D) 22.5mm × 96.5mm × 126.2mm

Weight 120g

Ambient data

T

able 174: Ambient data MOC1

MOC1

Enclosure rating (IEC60529) IP20

Ambient operating temperature

(UL/C

SA: surrounding air tempera‐

ture)

-25 ... +55°C

Storage temperature -25 ... +70°C

Air humidity ≤95%, non-condensing

Operating altitude Max. 2,000m above sea level (80kPa)

Vibration resistance 5–150Hz/1G (EN60068-2-6)

10–500Hz/3G

r

ms

(EN60068-2-64)

Shock resistance, continuous shock 15g, 11ms (EN 60068-2-27)

Shock resistance, single shock 30g, 11ms (EN 60068-2-27)

12 TECHNICAL DATA

164

O P E R A T I N G I N S T R U C T I O N S | Flexi Soft Modular Safety Controller 8012478/1IG6/2023-02-24 | SICK

Subject to change without notice

Loading...

Loading...