Siemens Energy & Automation 9-17

SIMOREG DC Master Base Drive Panel Operating Instructions

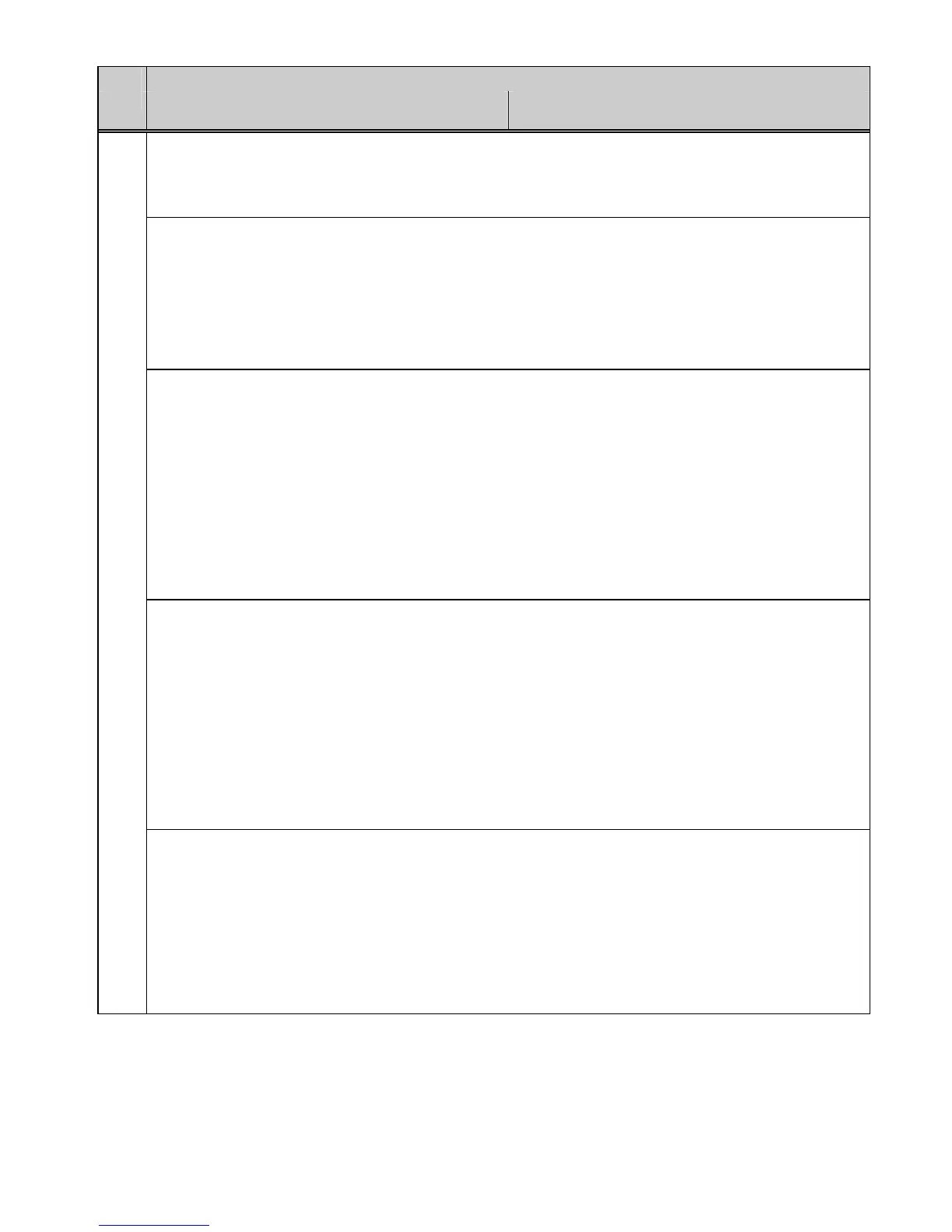

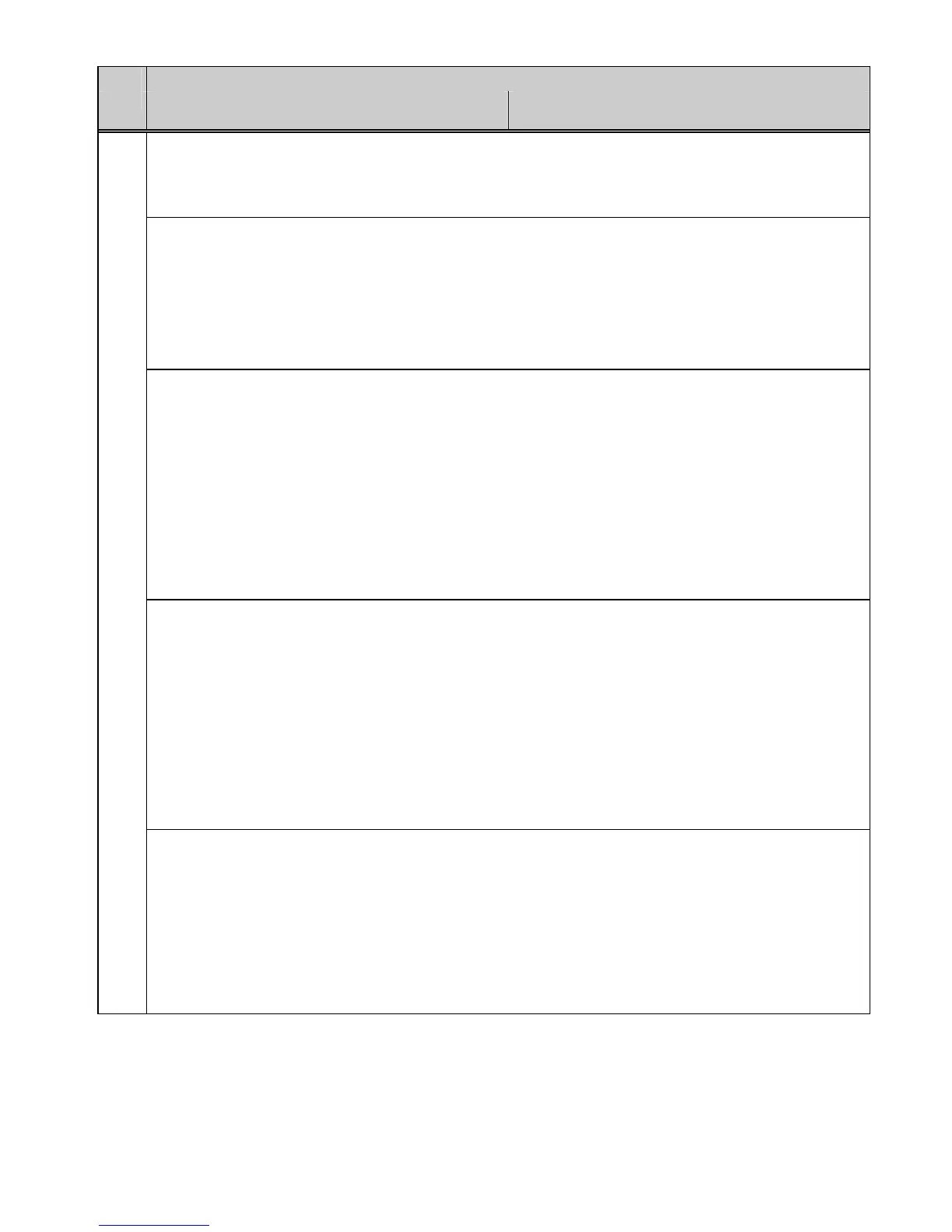

Fault Description

No.

Cause as a function of fault value

(r047.001, r949.001 or r949.009 with acknowledged error)

Further information (r047.002 to r047.016)

20 Current limit is too low

(With speed controller optimization run: Less than 30% or 45% of P100 (I

A,motor

) + the armature current required for zero

speed,

With optimization run for friction moment and moment of inertia compensation: Less than 20% of P100 (I

A, motor

) + the

armature current required for a steady-state speed corresponding to 10% of maximum speed)

21 Field weakening range is too wide (n

act

< +7% n

max

produces |EMF| > 54% setpoint EMF)

(setpoint EMF= K289= P101 – P100

*

P110)

Possible cause:

• Maximum speed setting is incorrect

• Pulse encoder parameters are incorrect (P140 to P143)

• Parameters for tachometer adaptation are incorrect (P741)

• Setpoint EMF is not correct (P101, P100, P110)

• Caution:

Even a high absolute negative actual speed value can produce an | EMF | of > 54% setpoint EMF

22 With speed controller optimization run:

With an acceleration current equaling 20% or 30% of P100 (I

A, motor

) + armature current required for zero speed or

With optimization run for friction moment and moment of inertia compensation:

With an acceleration current equaling the current required to achieve a steady-state speed of 10% of maximum speed +

20% of P100 (I

A, motor

), the maximum speed cannot be reached within 45s +7%

Possible cause:

• Centrifugal mass is too large

• Drive is blocked, heavily speed-dependent or excessively high load torque

• “Active” load is attempting to maintain a certain speed

Possible remedy:

• Increase P100 while the optimization run is in progress in order to raise the applied acceleration current during

optimization (during the speed controller optimization run, a maximum of 45% of I

A, motor

(+ armature current for zero

speed) is applied as the armature current setpoint, I

A,motor

(P100) can thus be increased to 2.2 times the value at

maximum without exceeding 100% I

A, motor

during optimization)

23 With speed controller optimization run:

With an acceleration current equaling 20% or 30% of P100 (I

A, motor

) + armature current required for zero speed or

With optimization run for friction moment and moment of inertia compensation:

With an acceleration current equalling the current required to achieve a steady-state speed of 10% of maximum speed +

20% of P100 (I

A, motor

), the maximum speed or 100% of setpoint EMF cannot be reached within 90s +13%

Possible cause:

• Flywheel mass is too large

• Drive is blocked, heavily speed-dependent or excessively high load torque

• “Active” load is attempting to maintain a certain speed

Possible remedy:

• Increase P100 while the optimization run is in progress in order to raise the applied acceleration current during

optimization (during the speed controller optimization run, a maximum of 45% of I

A, motor

(+ armature current for zero

speed) is applied as the armature current setpoint, I

A,motor

(P100) can thus be increased to 2.2 times the value at

maximum without exceeding 100% I

A, motor

during optimization)

24 With speed controller optimization run:

The actual speed does not drop to below +2% of maximum speed or to below the speed threshold n

min

set in P370 within 2

minutes

With optimization run for field weakening:

The actual speed does not drop to below +2% of maximum speed or to below the speed threshold n

min

set in P370 within

10 minutes

With optimization run for friction moment and moment of inertia compensation:

The actual speed does not drop to below +2% of maximum speed or to below the speed threshold n

min

set in P370 within

11 or 2 minutes

Possible cause:

• Single-quadrant drive coasts to a standstill too slowly

Loading...

Loading...