10-36 SIEMENS Energy & Automation

SIMOREG DC Master Base Drive Panel Operating Instructions

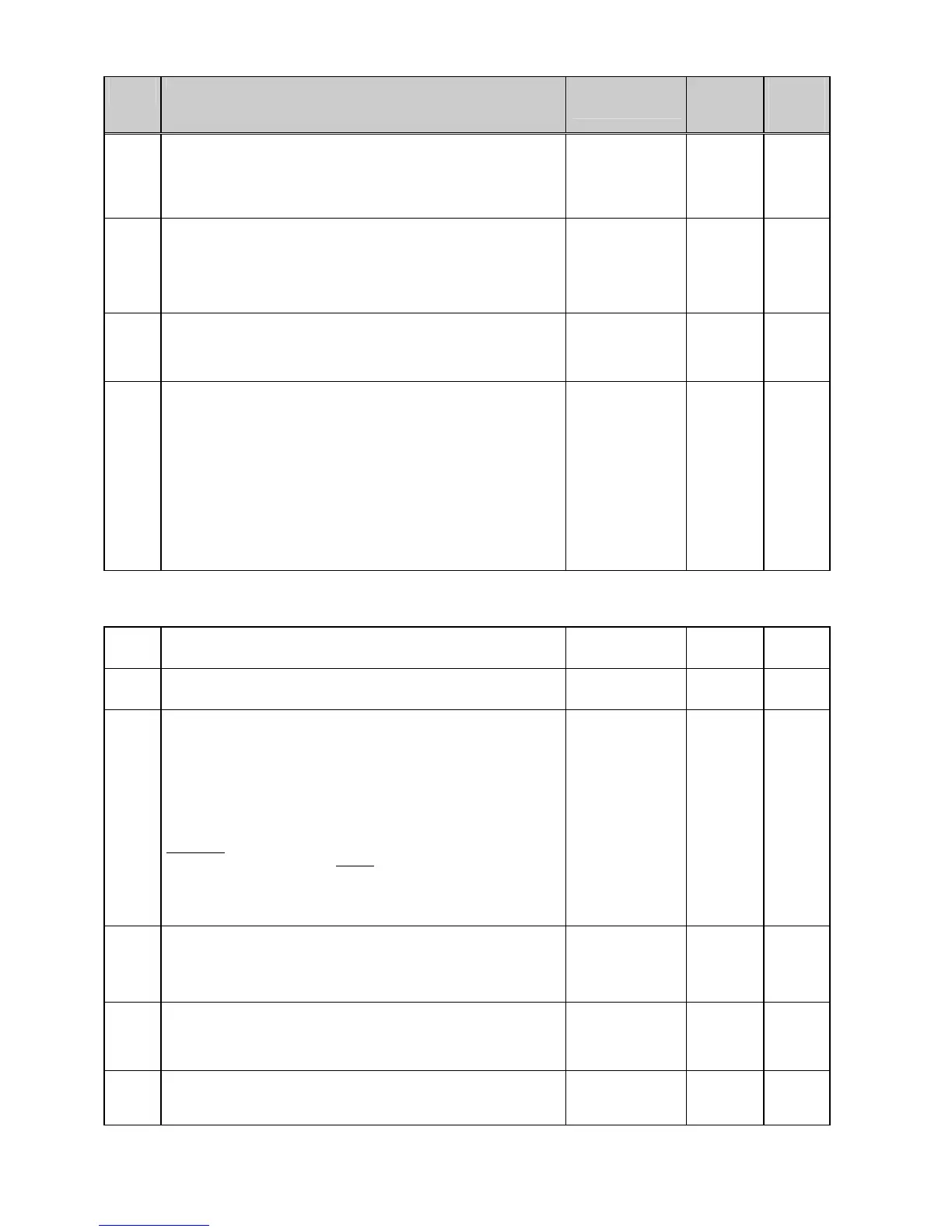

PNU

Description Value range

[Unit]

Steps

No. indices

Factory

setting

Type

See

Change

(Access /

Status)

P229

*

FDS

(G152)

Control of I component tracking for slave drive

0 On a slave drive, the I component of the speed controller is

made to follow such that M(set, ncontr.) = M(set, limit),

the speed setpoint is set to the actual speed value

1 Tracking deactivated

0 to 1

1

Ind: 4

FS=0

Type: O2

P052 = 3

P051 = 40

Offline

P230

FDS

(G152)

Setting period of speed controller integrator [SW 1.9 and later]

After a positive edge at the binector set in P695, the integrator of the speed

controller is set to the instantaneous value of the connector set in P631.

If a time of > 0 is set on P230, this setting operation is not performed just

once, but the speed controller integrator is set continually to the setting

value for the parameterized time period.

0 to 10000

[ms]

1ms

Ind: 4

FS=0

Type: O2

P052 = 3

P051 = 40

on-line

P234

*

FDS

(G152)

Set speed controller P component to zero

0 Set controller P component to zero (i.e. to obtain a pure I

controller)

1 Controller P component is active

0 to 1

1

Ind: 4

FS=1

Type: O2

P052 = 3

P051 = 40

Offline

P236

*

FDS

Specifying the dynamic response of the speed control loop

[SW 2.0 and later]

The parameter value is used as the optimization criterion for the speed

control loop.

Note:

Changes to this value do not take effect until the speed controller

optimization run (P051 = 26, see Section 7.5) has been executed.

Setting instructions:

- For drives, for example, with gear backlash, optimization should be

started with low dynamic response values (from 10%).

- For drives with top synchronism and dynamic response requirements,

values up to 100% should be used.

10 to 100

[%]

1

Ind: 4

FS=75

Type: O2

P052 = 3

P051 = 40

online

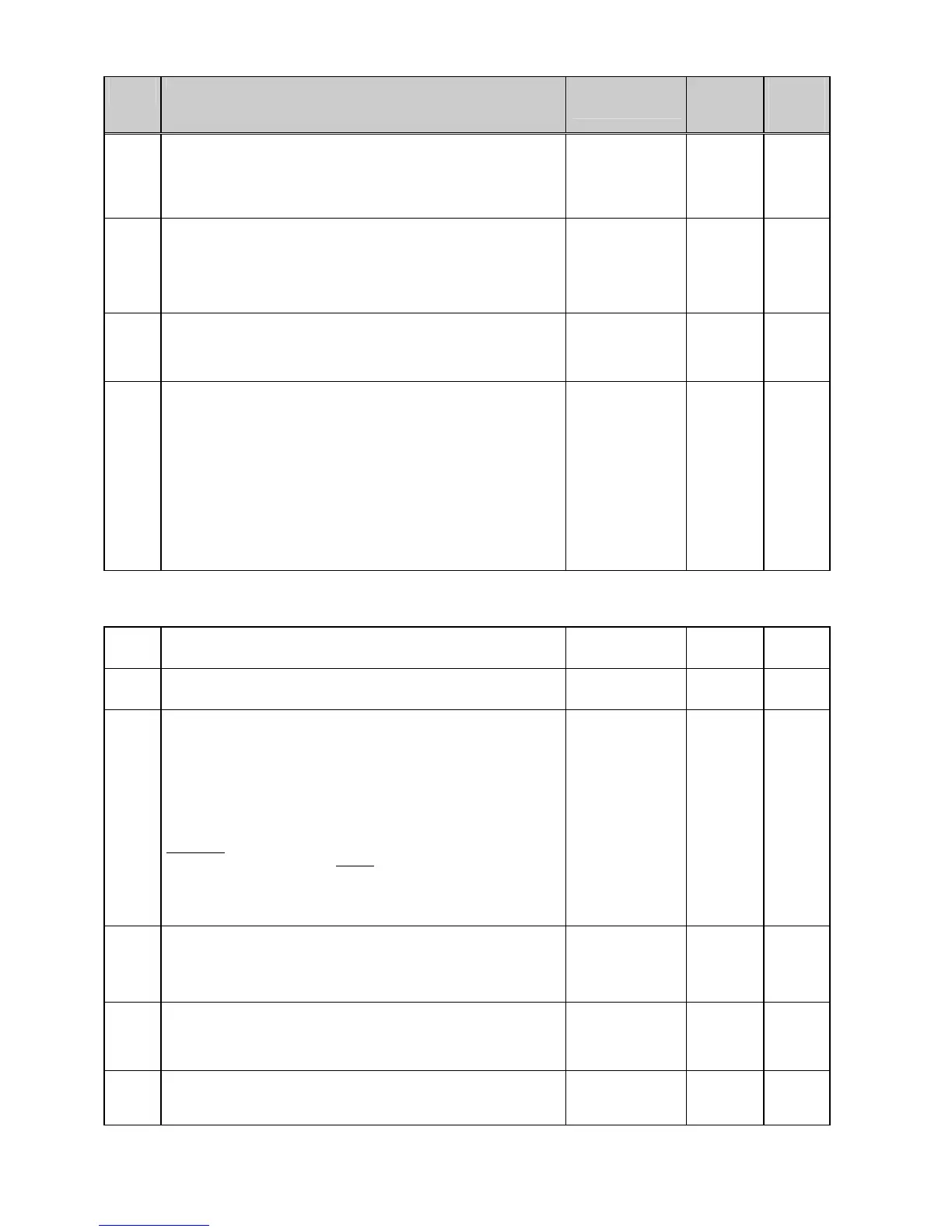

10.12 Closed-loop field current control, field gating unit

P250

FDS

(G166)

Alpha G limit (field)

Rectifier stability limit for firing angle of field converter

0 to 180

[degrees]

1 degree

Ind: 4

FS=0

Type: O2

P052 = 3

P051 = 40

Online

P251

FDS

(G166)

Alpha W limit (field)

Inverter stability limit for firing angle of field converter

0 to 180

[degrees]

1 degree

Ind: 4

FS=180

Type: O2

P052 = 3

P051 = 40

Online

P252

*

FDS

(G166)

Filtering of line frequency correction (field)

The internal line synchronization for the field gating pulses derived from the

field mains infeed terminals is filtered with this time constant. In operation

on "weak" power supplies with unstable frequencies, for example, on a

diesel-driven generator (isolated operation), the filter time constant must be

set lower than for operation on "constant V/Hz" systems in order to achieve

a higher frequency correction speed.

Using the units position, the line synchronization function can be altered

additionally

as follows:

When the parameter is set to an uneven

number, the measured line zero

crossings for line synchronization are subjected to an extra "filter", may

improve performance in the case of difficulties with brief mains interruptions

(e.g. power supply via sliding current collectors), but may only be set for

constant V/Hz power supplies (not for weak isolated supply systems).

0 to 200

[ms]

1ms

Ind: 4

FS=200

Type: O2

P052 = 3

P051 = 40

Offline

P253

*

FDS

(G166)

Control word for field precontrol

0 Field precontrol disabled, precontrol output = 180°

1 Field precontrol active, output is dependent on field current

setpoint, field line voltage, P112

0 to 1

1

Ind: 4

FS=1

Type: O2

P052 = 3

P051 = 40

Offline

P254

*

FDS

(G166)

Set field current controller I component to zero

0 Set controller I component to zero (i.e. to obtain pure P

controller)

1 Controller I component is active

0 to 1

1

Ind: 4

FS=1

Type: O2

P052 = 3

P051 = 40

Offline

P255

FDS

(G166)

Field current controller P gain

This parameter is set automatically during the optimization run for precontrol

and current controller (armature and field) (P051=25).

0.01 to 100.00

0.01

Ind: 4

FS=5.00

Type: O2

P052 = 3

P051 = 40

Online

Loading...

Loading...