Programming

8.3 Axis movements

8-150

SINUMERIK 802D sl Operation and Programming Nibbling (BP-N), 06/2006 Edition

6FC5 398-3CP10-0BA0

8.3 Axis movements

8.3.1 Linear interpolation at rapid traverse: G0

Functionality

The rapid traverse movement G0 is used for fast positioning of the tool, but not directly for

machining of the workpiece.

It is possible to traverse all axes simultaneously – along a straight path.

For each axis, the maximum speed (rapid traverse) is defined in machine data. If only one

axis traverses, it uses its rapid traverse. If two or three axes are traversed simultaneously,

the path velocity (e.g. the resulting velocity at the tool tip) must be selected such that the

maximum possible path velocity with consideration of all axes involved results.

A programmed feedrate (F word) has no meaning for G0. G2/G3 remains active until can-

celed by another instruction from this G group (G0, G1, G3, ...).

Programming

G0 X... Y.. ; Cartesian coordinates

G0 AP=... RP=... ; Polar coordinates

G0 AP=... RP=... ; Cylinder coordinates (3-dimensional)

Note: Another option for linear programming is available with the angle specification

ANG=...

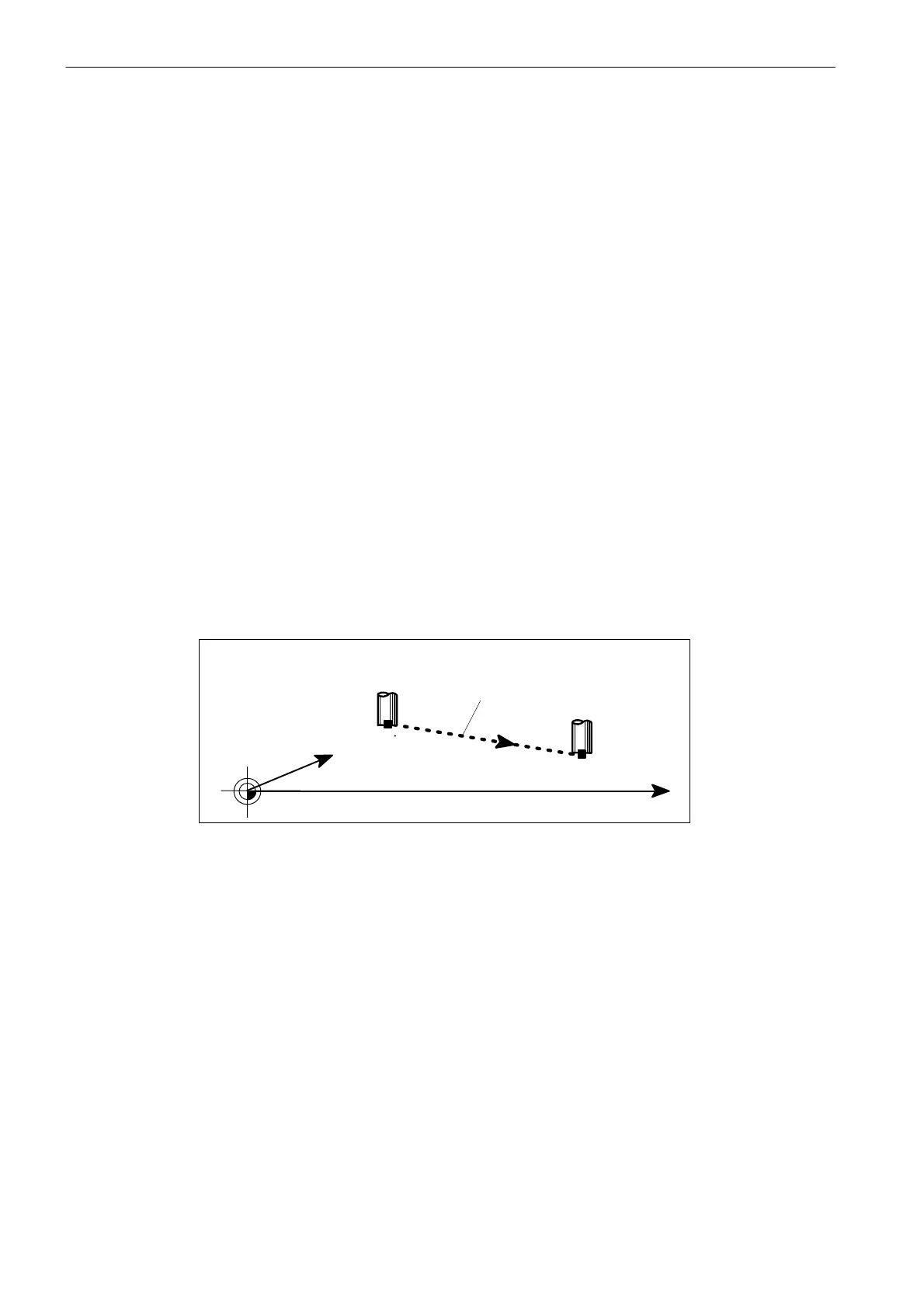

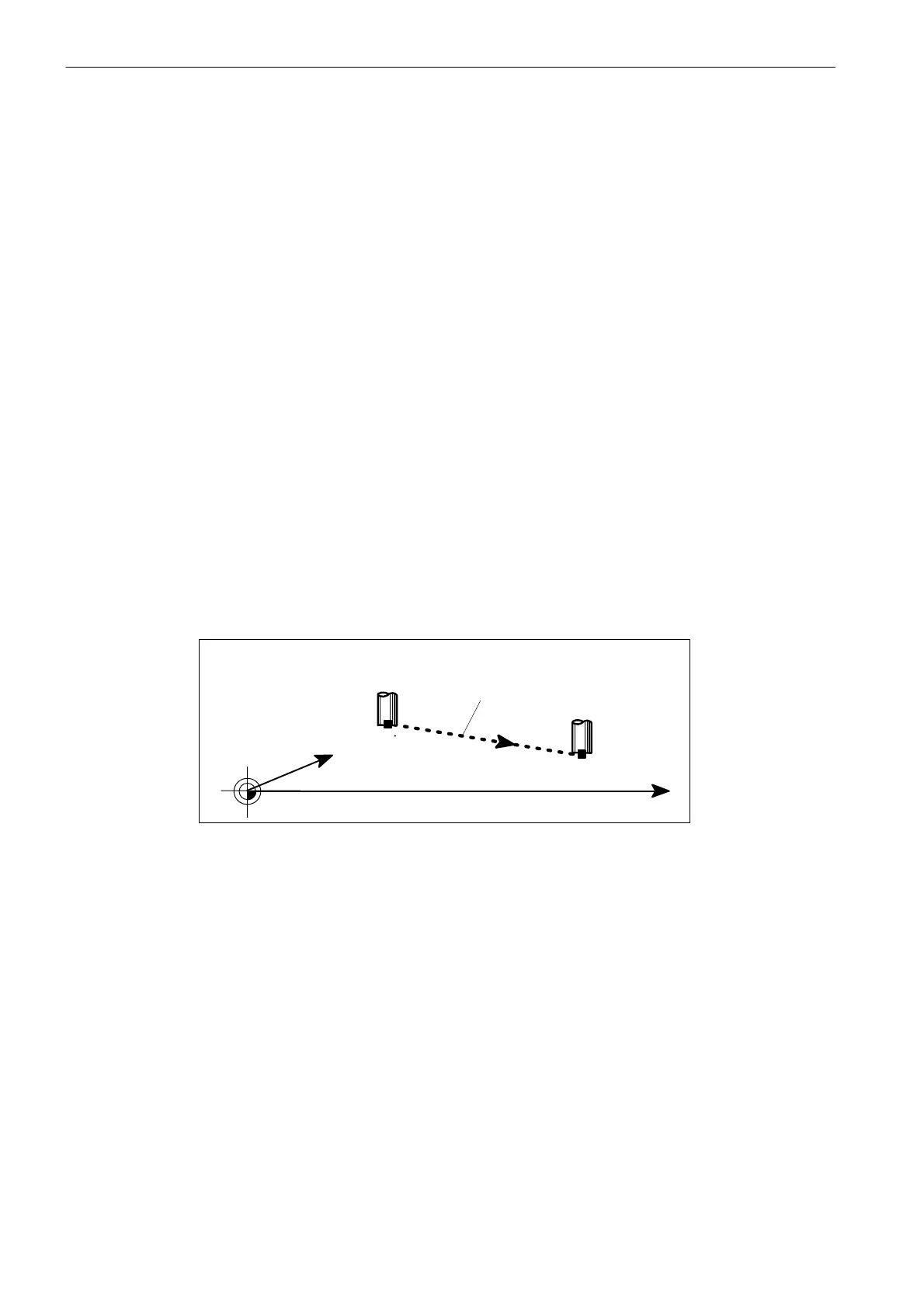

X

Y

P1

P2

Straight path

Fig. 8-14 Linear interpolation with rapid traverse from point P1 to P2

Programming example

N10 G0 X100 Y150 Z65 ; Cartesian coordinate

...

N50 G0 RP=16.78 AP=45 ; Polar coordinate

Information

Another group of G functions exists for movement to the position (see Subsection 8.3.11

“Exact stop / continuous-path control mode: G60, G64”).

For G60 exact stop, a window with various precision values can be selected with another G

group. For exact stop, an alternative instruction with non-modal effectiveness exists: G9.

You should consider these options for adaptation to your positioning tasks.

Loading...

Loading...