Setup

3.2 Entering / modifying a work offset

3-39

SINUMERIK 802D sl Operation and Programming Nibbling (BP-N), 06/2006 Edition

6FC5 398-3CP10-0BA0

3.2 Entering / modifying a work offset

Functionality

After the reference point approach, the actual-value memory and thus also the actual-value

display are referred to the machine zero. A machining program, however, is always referred

to the workpiece zero. This offset must be entered as the work offset.

Operating sequences

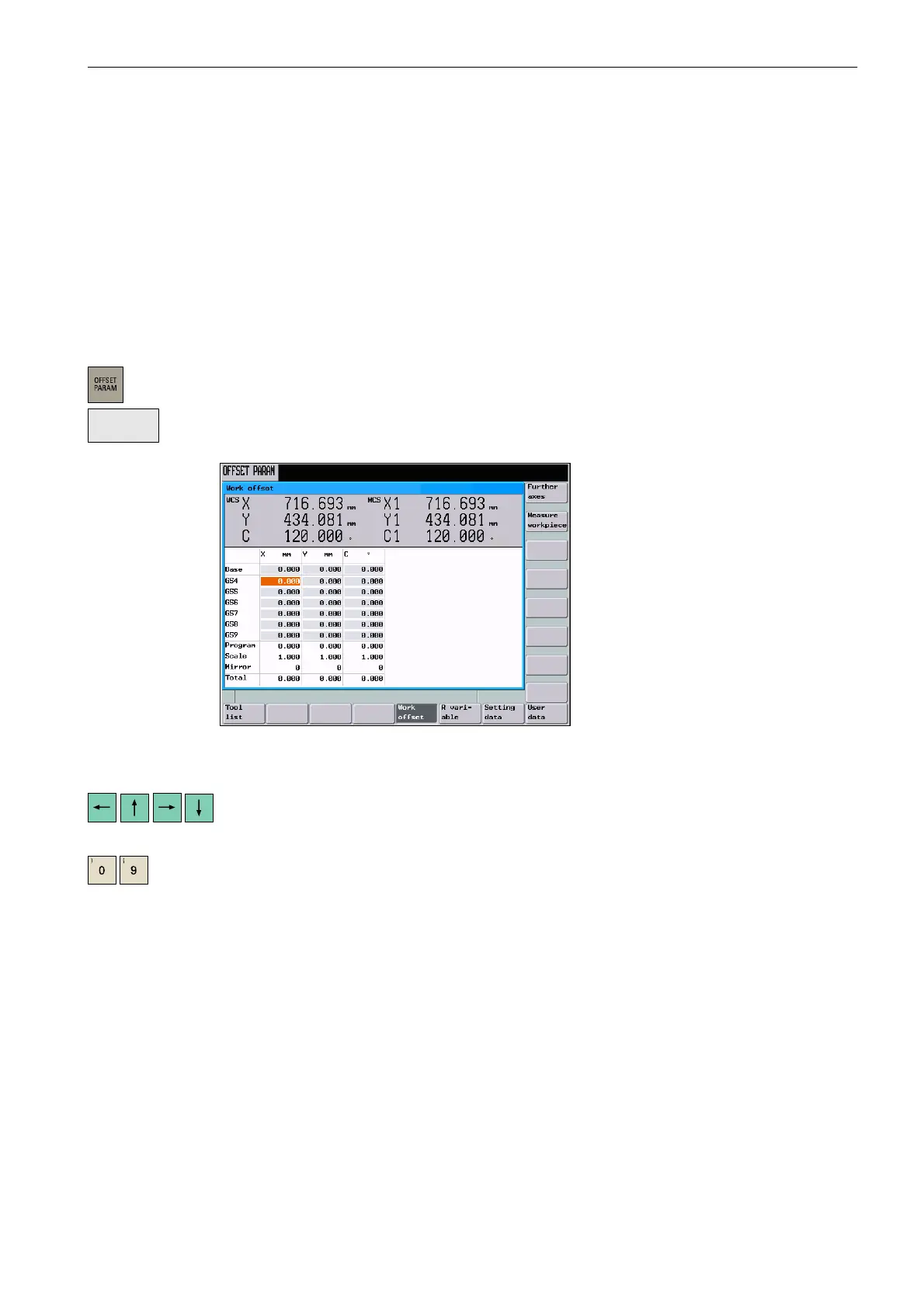

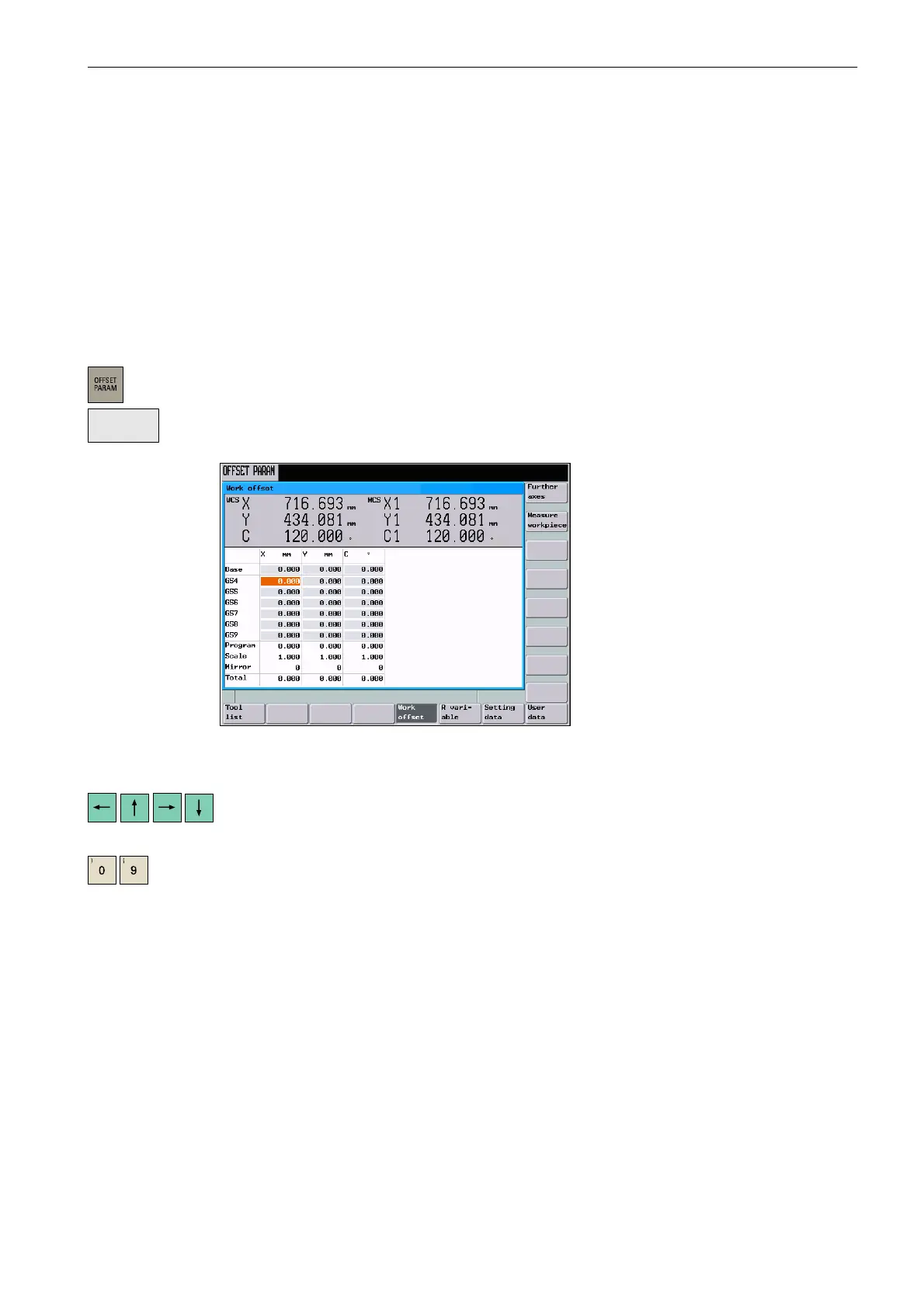

You are in the “Offset parameters” operating area.

Selecting <Work offset> opens an overview of the settable work offsets. The screenform

additionally contains the values of the programmed work offset, of the active scaling factors,

the “Mirroring active” status display and the total of all active work offsets.

Fig. 3-6 The “Work offset” window

Position the cursor bar on the input field to be changed

and enter the value(s). Either move the cursor a press the <Input> key to accept the values

from the input fields into the work offsets.

Work

offset

Loading...

Loading...