Manually Controlled Mode

4.1 JOG mode – “Position” operating area

4-51

SINUMERIK 802D sl Operation and Programming Nibbling (BP-N), 06/2006 Edition

6FC5 398-3CP10-0BA0

Parameters

Table 4-1 Description of the parameters in the JOG start screen

Parameter Explanation

MCS

X

Y

C1

C2

Displays the address of the axes existing in the machine coordinate system (MCS)

+X

....

–Y

If you traverse an axis in the positive (+) or negative () direction, a plus or minus sign will appear in

the relevant field.

If the axis is already in the required position, no sign is displayed.

Position

mm

These fields display the current position of the axes in the MCS or WCS.

Repos. offset If the axes are traversed in the “Program interrupted” condition in the JOG mode, the distance tra-

versed by each axis is displayed referred to the interruption point.

G function Displays important G functions

Feed F mm/

min

Displays the path feedrate actual value and setpoint

Tool Displays the currently active tool with the current edge number

Softkeys

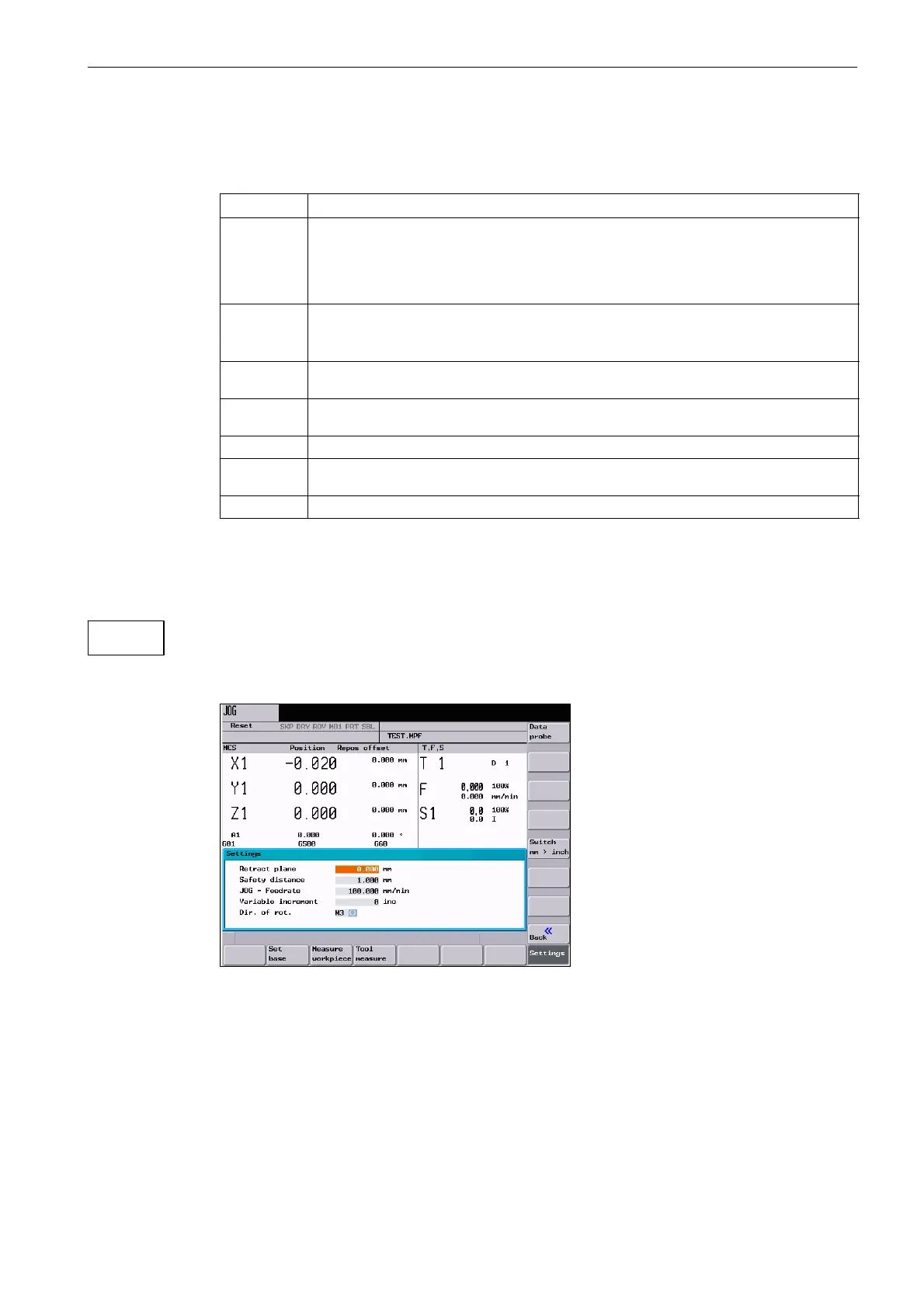

The interactive screenform shown below is intended to set the retraction plane, the safety

clearance and the direction of rotation of the spindle for automatically generated part pro-

grams in the MDA mode. Furthermore, the values for the JOG feedrate and the variable size

of increments can be set.

Fig. 4-3

Safety clearance: Safety clearance to the workpiece surface

This value defines the minimum clearance between the workpiece surface and the work-

piece.

JOG feedrate: Feedrate value in the JOG mode

Settings

Loading...

Loading...