10.03

4.3 Closed-loop velocity control

4-109

Siemens AG, 2003. All rights reserved

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) - 10.03 Edition

A negative P gain setting may be useful for oscillation damping. Negative gain

settings are permissible. The gain is specified in relation to the drive servo gain

setting. 100% means that if the distance-to-go is equal to the maximum speed

(MD 5440: POS_DRIVE_SPEED_LIMIT, MD 5441:

NEG_DRIVE_SPEED_LIMIT), the full nominal valve voltage will be output as

the P component.

The P gain set in MD 5407 SPEEDCTRL_GAIN is referred to the controlled

system gain set in MD 5435: CONTROLLED_SYSTEM_GAIN.

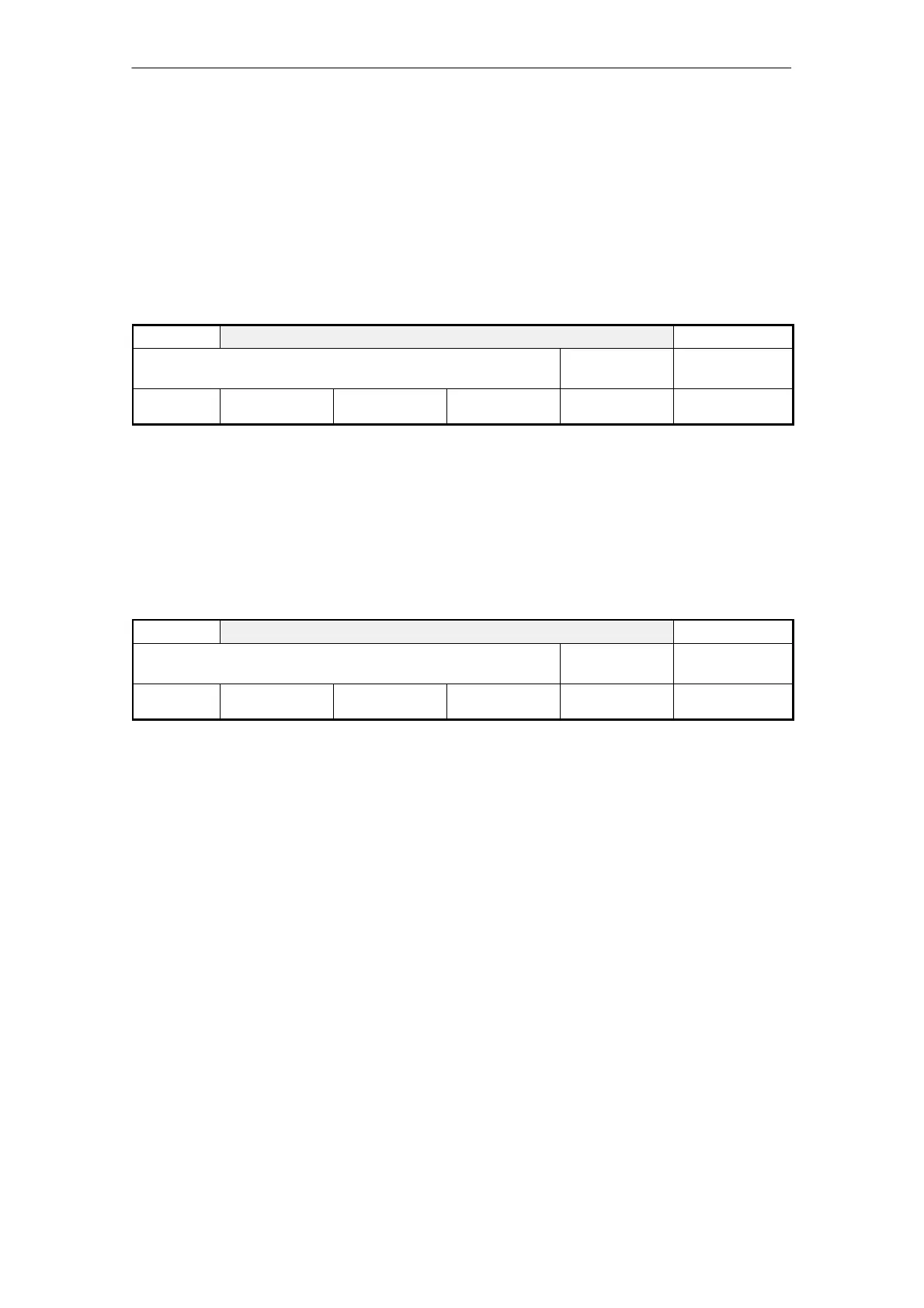

5409

SPEEDCTRL_INTEGRATOR_TIME [n] 0...7 index of the parameter set

Cross reference: -

Reset time of velocity controller Related to:

HLA

Protection level:

3/3

Unit:

ms

Default:

50.0

Minimum:

0.0

Maximum:

2000.0

Data type:

FLOAT

Active:

Immediately

The integral-action component can be deactivated by setting the reset time to

zero. For a negative P gain setting, the reset time is interpreted as a negative

value so that the compensation always acts as negative feedback.

The integrator can be activated/deactivated via the PLC. The current status is

returned to the PLC.

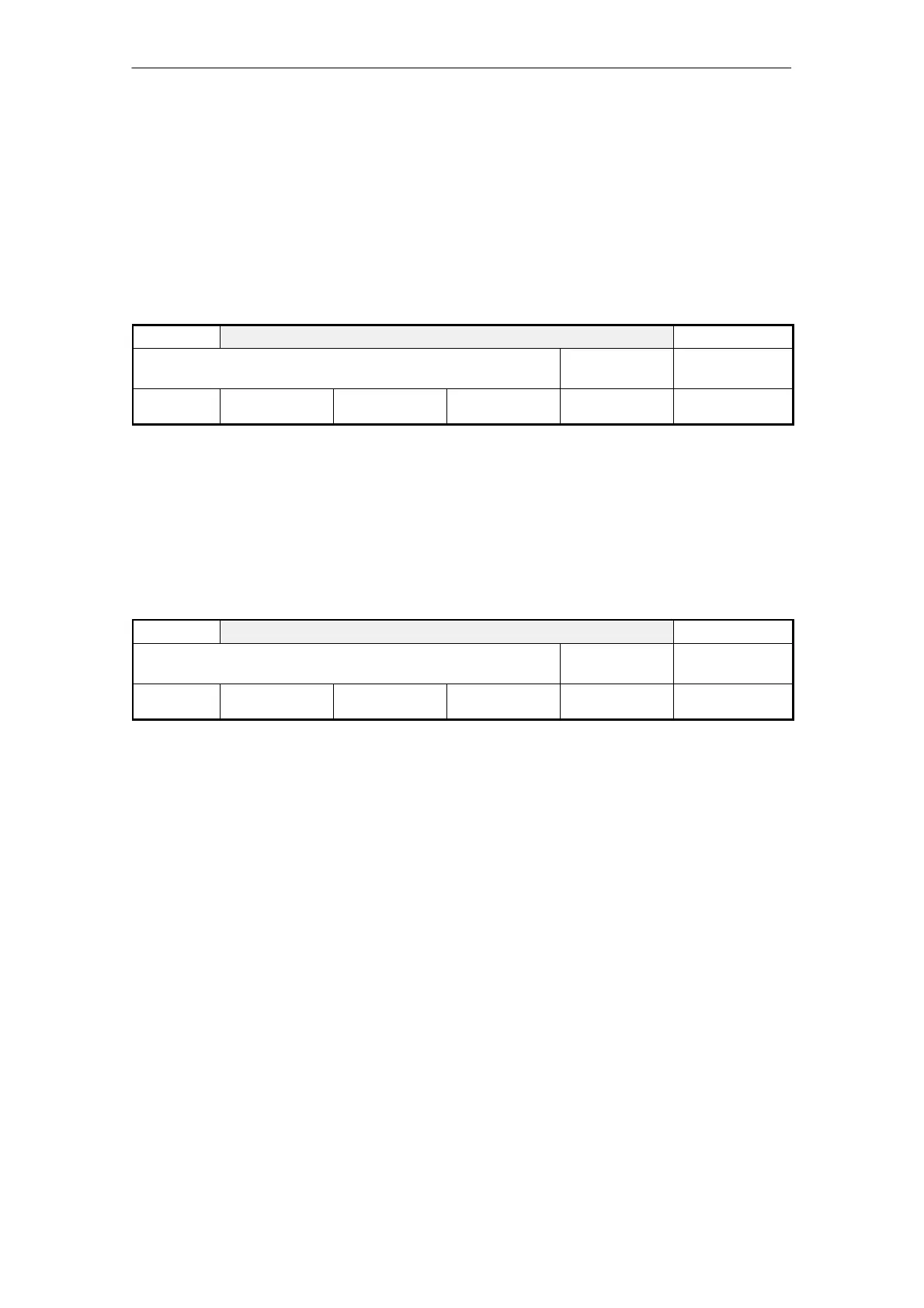

5421

SPEEDCTRL_INTEGRATOR_FEEDBK [n] 0...7 index of the parameter set

Cross reference: -

Time constant of integrator feedback Related to:

HLA

Protection level:

3/3

Unit:

ms

Default:

0.0

Minimum:

0.0

Maximum:

1000.0

Data type:

FLOAT

Active:

Immediately

The integrator of the velocity controller loop is reduced to a 1st order low-pass

action with the configured time constant via a weighted feedback.

S Effect:

The output of the velocity controller integrator is limited to a value propor-

tional to the difference between setpoint and actual values (steady-state

proportional action).

S Applications:

Machining motions for position setpoint zero and dominant static friction can

be suppressed but result in a permanent distance-to-go, e.g. oscillation of

the position-controlled axis at zero speed (stick-slip effect) or overshooting in

the µm-step method.

S Setting notes:

Optimize this data starting from a high value until you find the best

compromise.

If the time constant integrator feedback v1 ms is set, feedback is disabled.

I component

Integrator

feedback

4 Firmware Drive Functions

02.99

Loading...

Loading...