39

• use the machine without verifying the existence of the minimum spaces required; this

conduct can cause accidents because the operator, by acting in confined spaces, may run

into impacts or stumbles.

Inadequate reactions due to equipment failure, accidents, etc.

An alarm is triggered every time an operation failure or fault is detected on the machine. The

fixed red light on the luminous column lights up and the operator panel screen indicates the

problem encountered.

In this case, the operator must not reset the alarm immediately, must carefully read the

message and transpose the content, because the message contains in most cases the

directions for its resolution. At this point, the operator must be able to judge if the resolution of

the problem falls within his competences and capabilities, or whether he should seek the

assistance of qualified personnel.

Any eventual repair operation of the machine must be preceded by the disconnection of the

machine from the energy sources and the apposition of a clearly visible sign indicating the

current state of maintenance.

7.6 Safety devices adopted

In the phase of machine design were considered the potential risks in which the operators are

subject during normal use. In this respect, the following devices have been prepared.

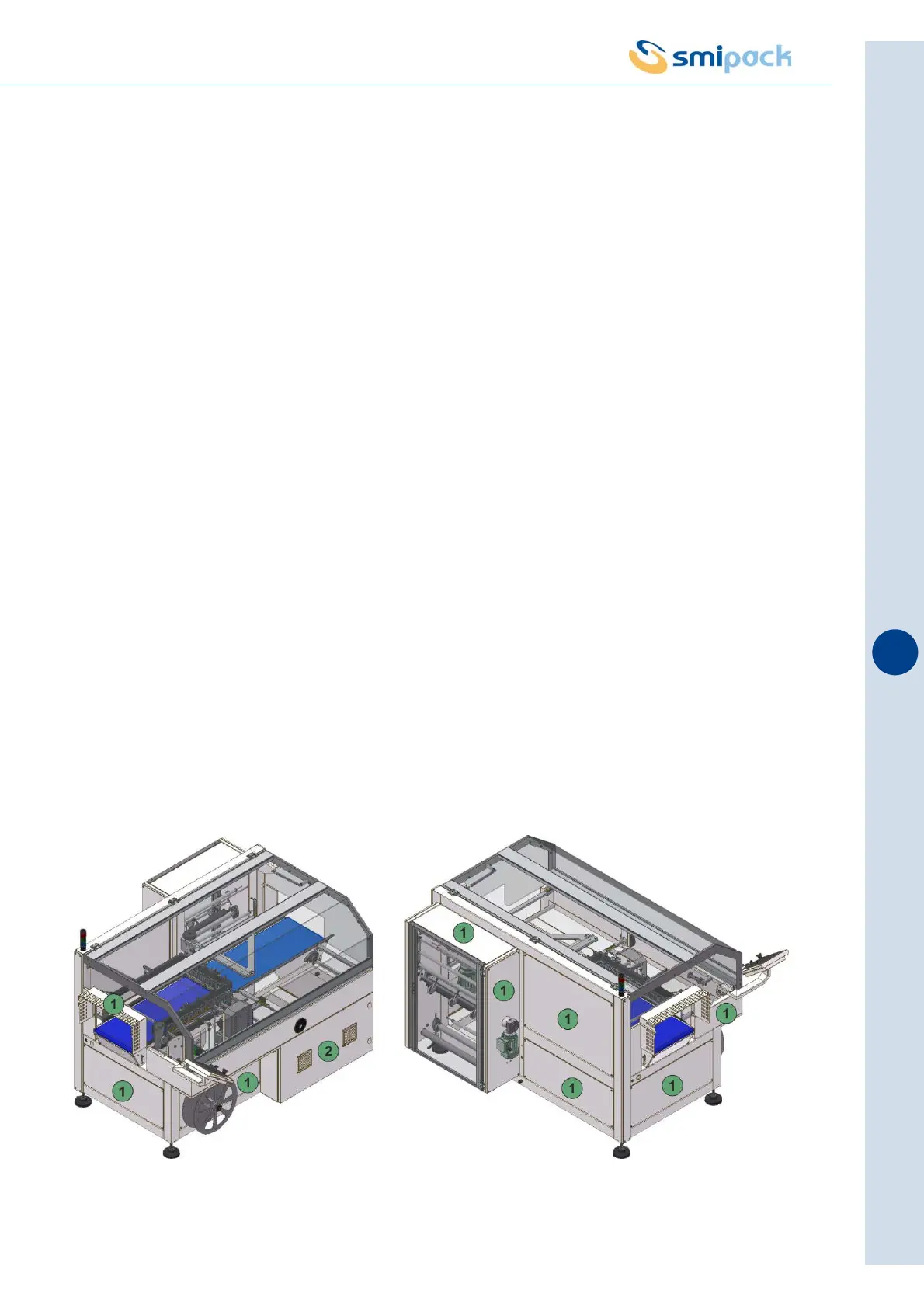

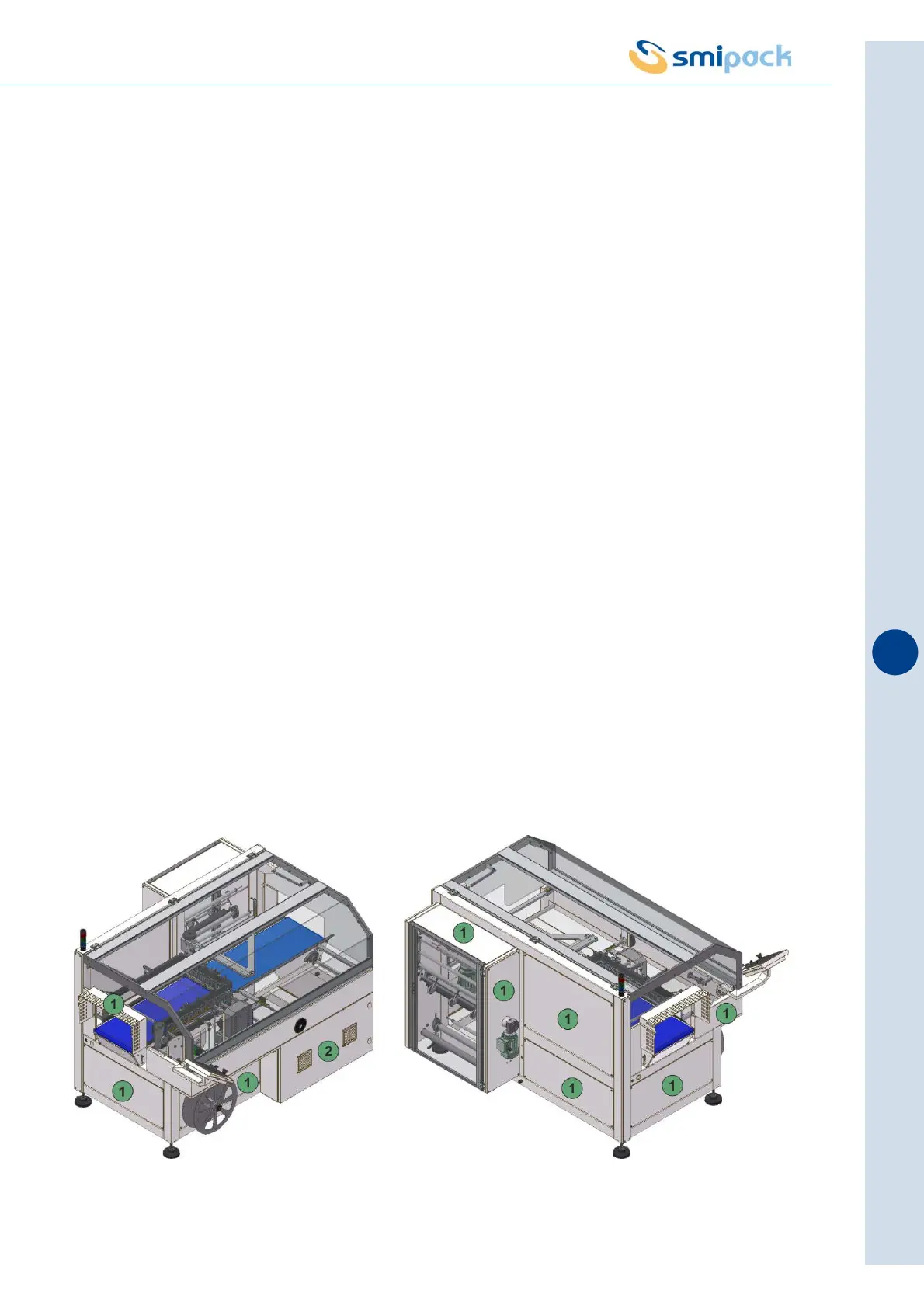

7.6.1 Fixed guards (1) or guards with key lock (2)

Are fixed elements in sheet metal or plexiglass that require the use of a tool to be disassembled

and are placed as shelter of moving mechanical parts that can create dangerous situations for

the operator.

Loading...

Loading...