59

To remove waste accumulated on the device, unscrew the knob (10) and remove the

containment disk (9).

If there are tensioning problems with discarded film it is possible to mount a special weight (11)

supplied with the machine. Generally there are tensioning problems when using very thick film

or unsuitable material.

The weight can be move as needed. Moving the weight towards the tensioning bar (12)

increases tensioning of the waste; moving it towards the lever fulcrum decreases tensioning.

Note - The waste film must be properly disposed in the plastic waste container or otherwise as

prescribed by the regulations in force of the country where the machine is installed.

8.8 Adjustments to facilitate the packaging of low parcks

The automatic angular wrapping machines are designed to process products of various sizes

without needing to modify the attitude of the machine. However, in order to improve wrapping

of low products (below 2 cm high), it is useful to carry out the following adjustments:

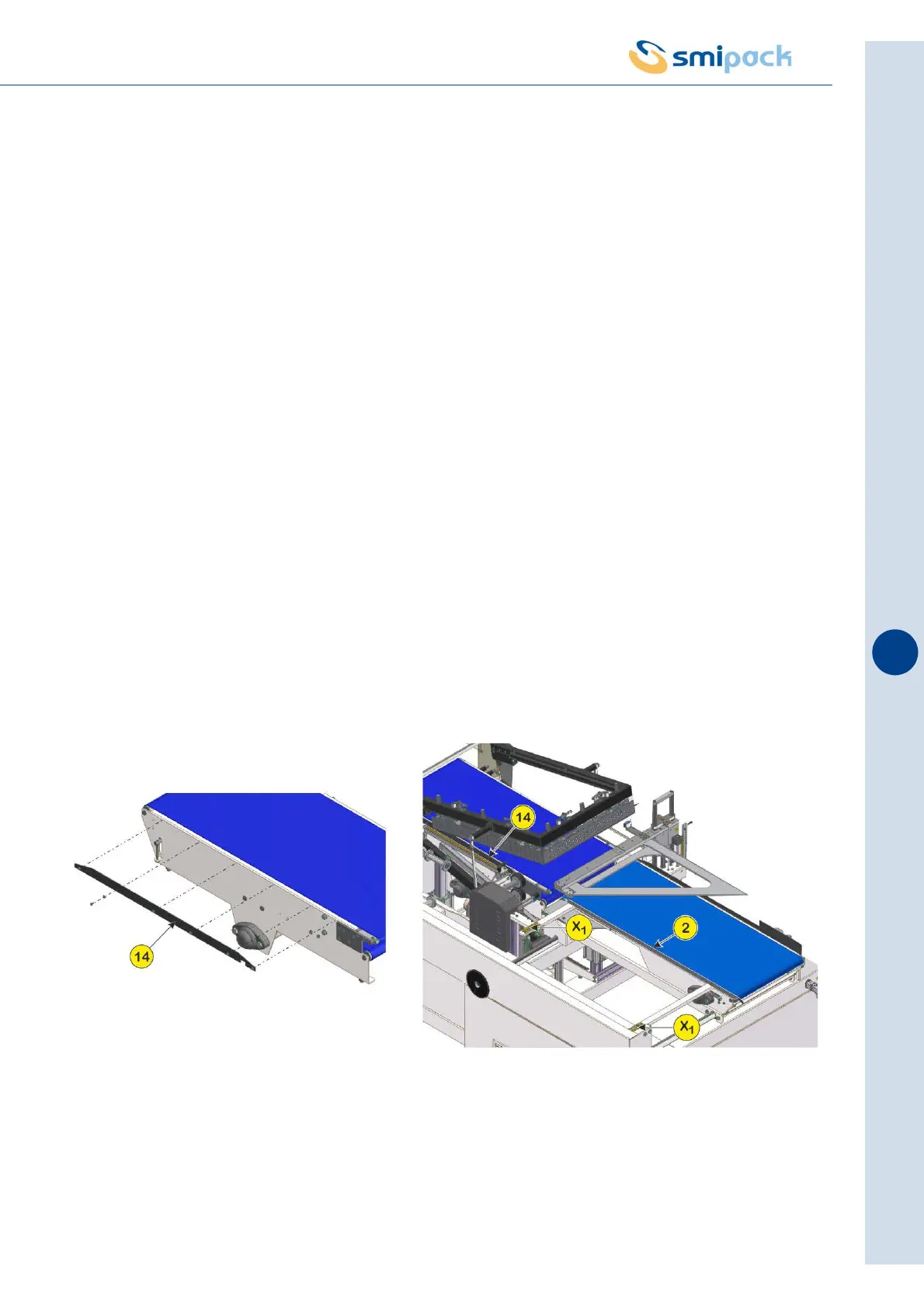

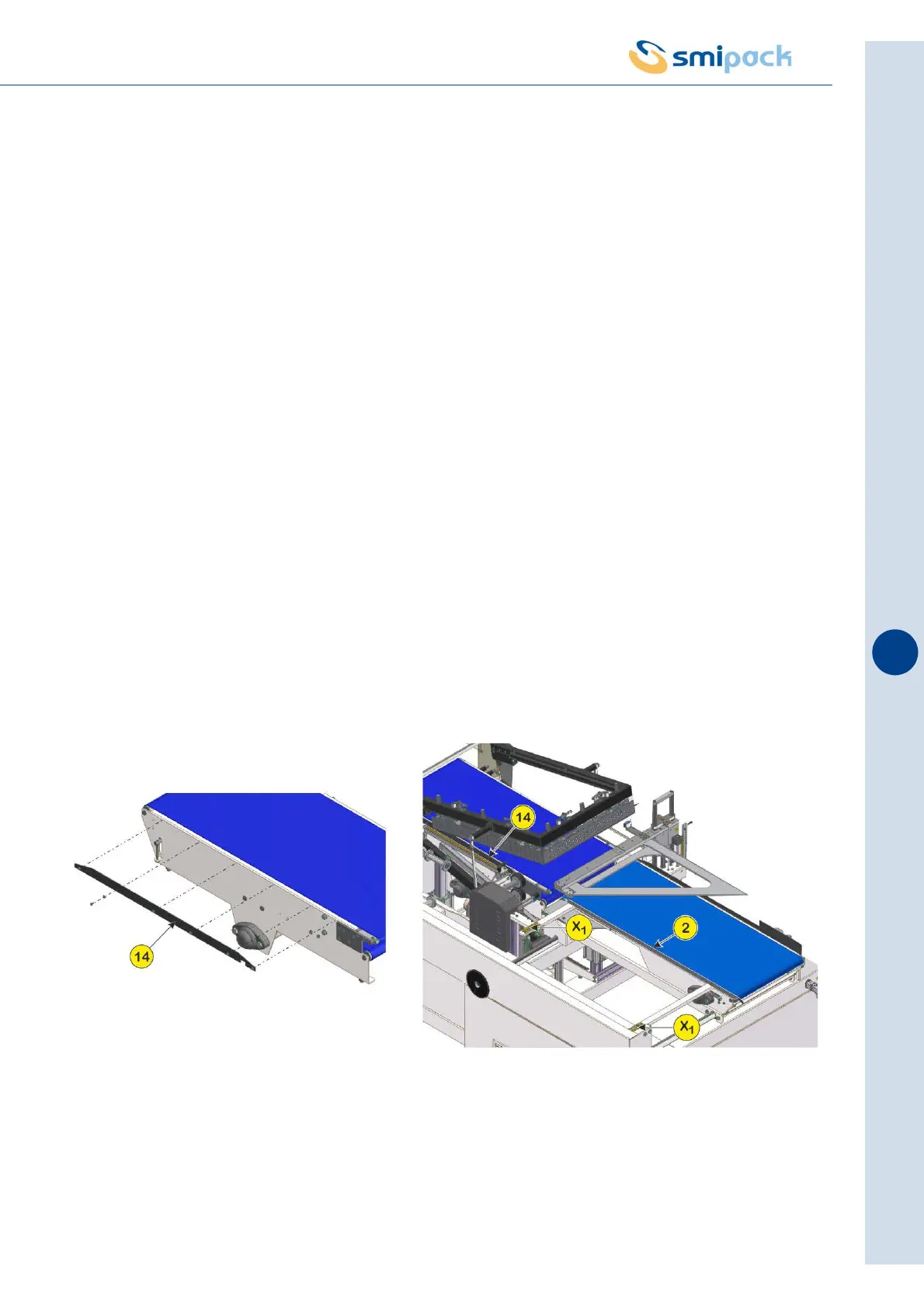

• remove the sideboard (14) on the machine's outfeed conveyor belt so the product can be

as close as possible to the sealing bar.

• position the product guide (2) so that the reference on the millimetric lines X

1

is “0”.

• Wind of the film as shown in the following figure, making sure that it passes below the

support (15).

Loading...

Loading...