41MS 362, MS 362 C

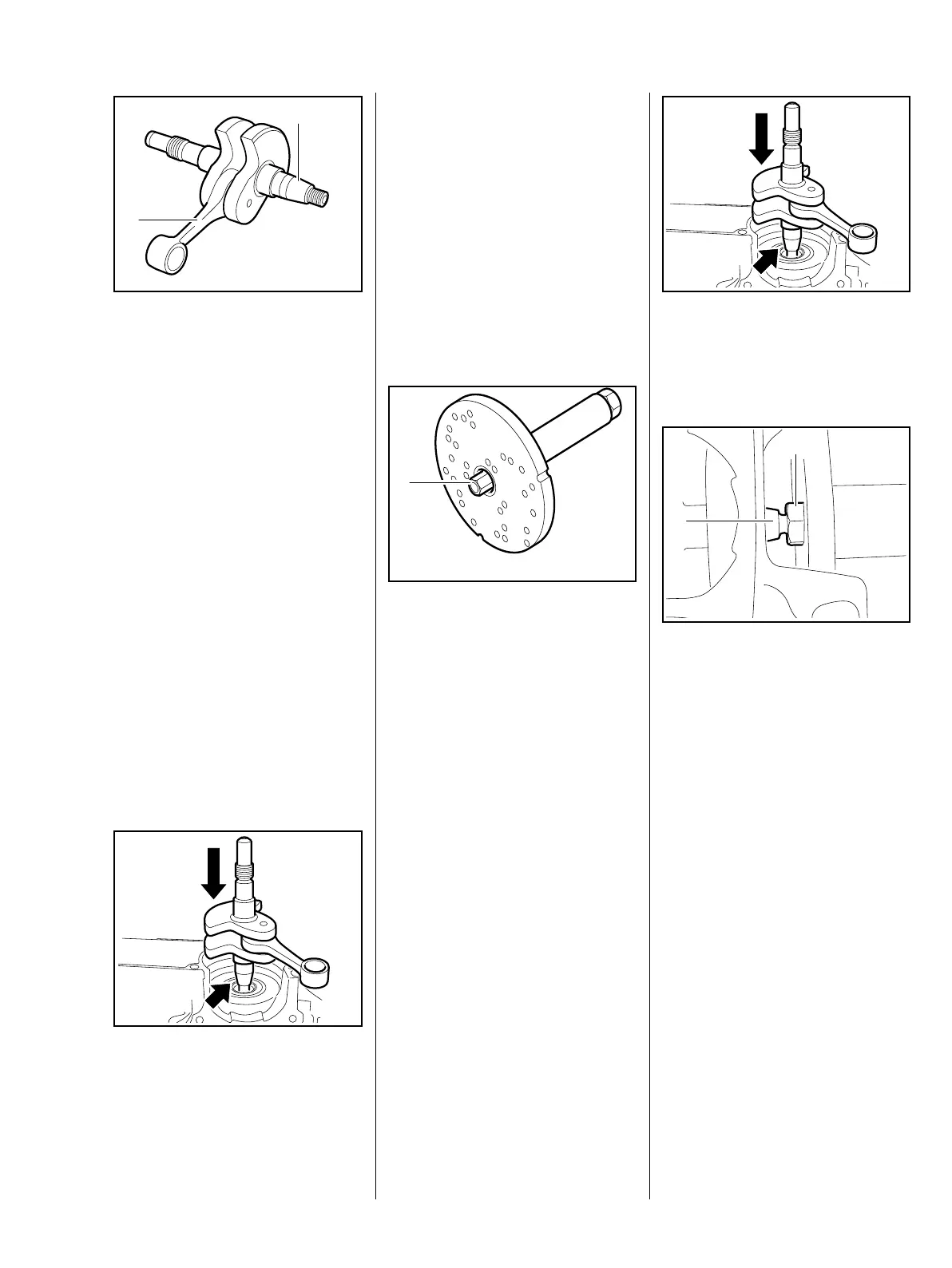

The crankshaft (1), connecting rod

(2) and needle bearing form an

inseparable unit. Always replace as

a complete unit.

– Check the two halves of the

crankcase and ball bearings and

replace if necessary, b 6.6.1

Before installing, clean the

crankshaft with a standard

commercial, solvent-based

degreasant containing no

chlorinated or halogenated

hydrocarbons.

Installing

Ignition side of crankcase

Take care not to damage the

crankshaft stub.

Sealing faces must not be damaged

in any way.

: Position the tapered stub of the

crankshaft (arrow) above the ball

bearing at the ignition side.

0001RA118 TG

1

2

0001RA119 TG

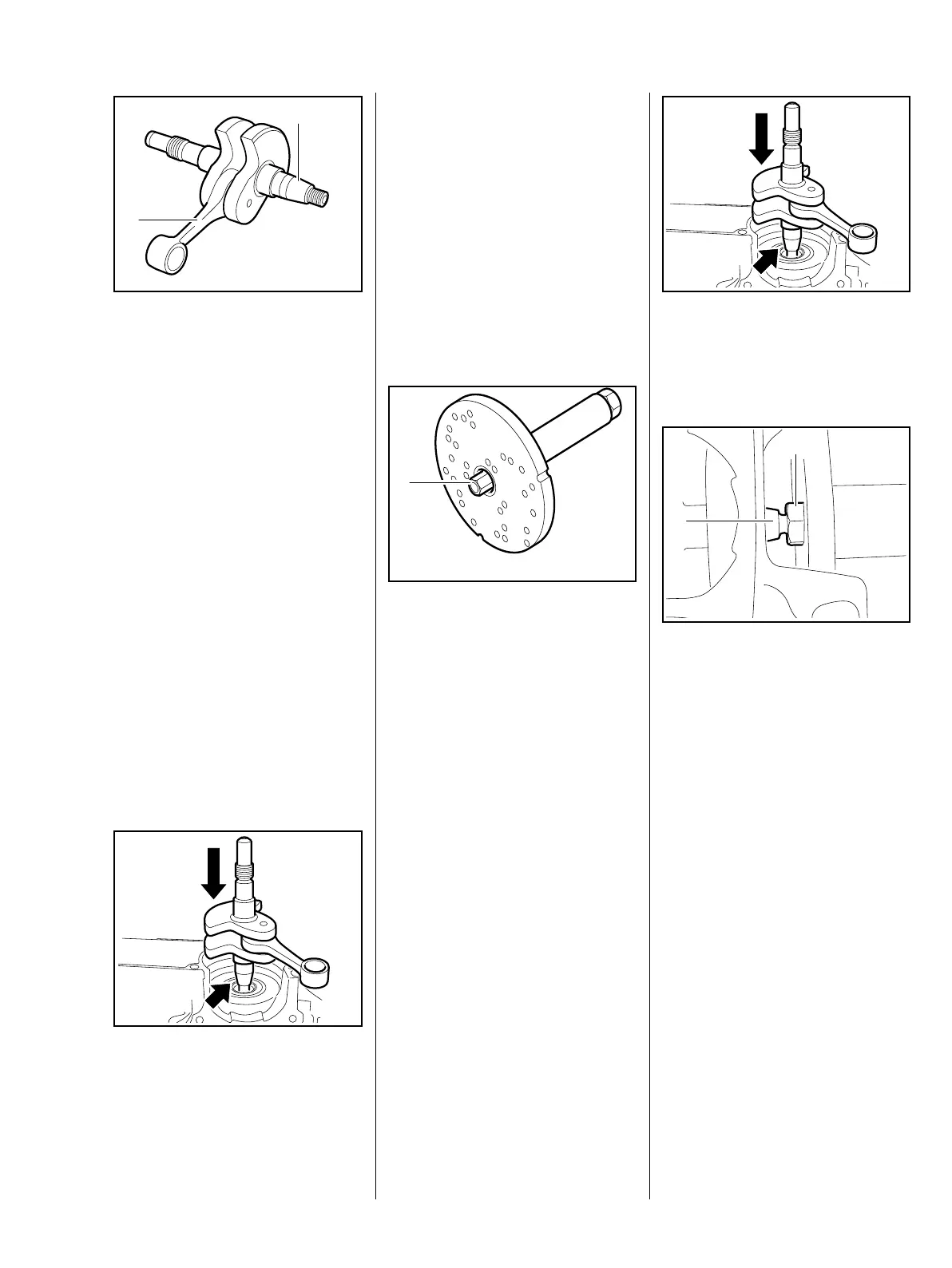

– Wear protective gloves

to reduce risk of burn injury.

– Heat the inner bearing race to

about 150°C (300°F).

: Push the crankshaft home as far

as stop.

This operation must be carried out

very quickly because heat is

absorbed by the crankshaft, and the

inner bearing race shrinks.

If it is not possible to heat the inner

bearing race, use service tool 5910

007 2200 or 5910 007 2201 to install

the crankshaft.

– Use drilled plate 5910 893 2103.

: Screw the threaded sleeve (1)

5910 893 2420 onto the spindle

as far as stop.

Coat tapered stub of crankshaft with

oil.

0001RA120 TG

1

.

: Position the tapered stub of the

crankshaft (arrow) above the ball

bearing at the ignition side and

push it home.

: Position the screw sleeve (2) on

the crankshaft thread (1) and

screw it into place.

0001RA119 TG

0001RA122 TG

1

2

Loading...

Loading...