96 MS 362, MS 362 C

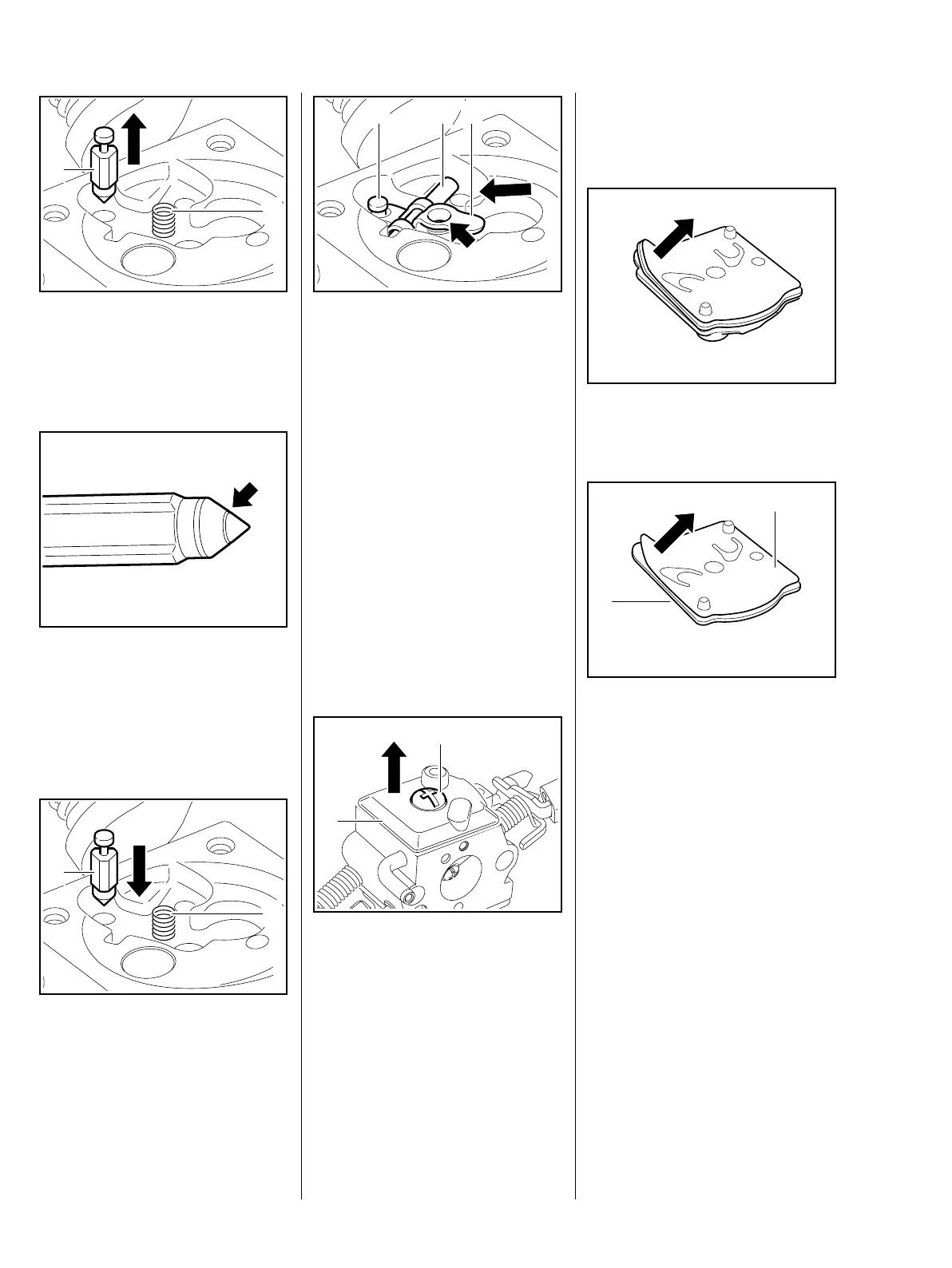

: Remove the inlet needle (1).

– Remove the spring (2). Inspect

and replace if necessary.

: If there is an annular indentation

(arrow) on the sealing cone of the

inlet needle, fit a new inlet

needle.

Installing

: Fit the inlet needle (1).

: Fit the spring (2) in the bore.

0001RA362 TG

1

2

165RA348 TG

1

2

0001RA363 TG

: Position the inlet control lever (3)

with spindle (2) on the spring

(arrow) first, then slide the inlet

control lever’s clevis into the

groove in the inlet needle (1).

Make sure the spring locates on the

control lever’s nipple.

– Press the inlet control lever down

and secure it with the screw.

– Check that the inlet control lever

moves freely.

– Install the metering diaphragm,

b 12.6.1

12.6.3 Pump Diaphragm

– Troubleshooting, b 3.6

– Remove the carburetor, b 12.5

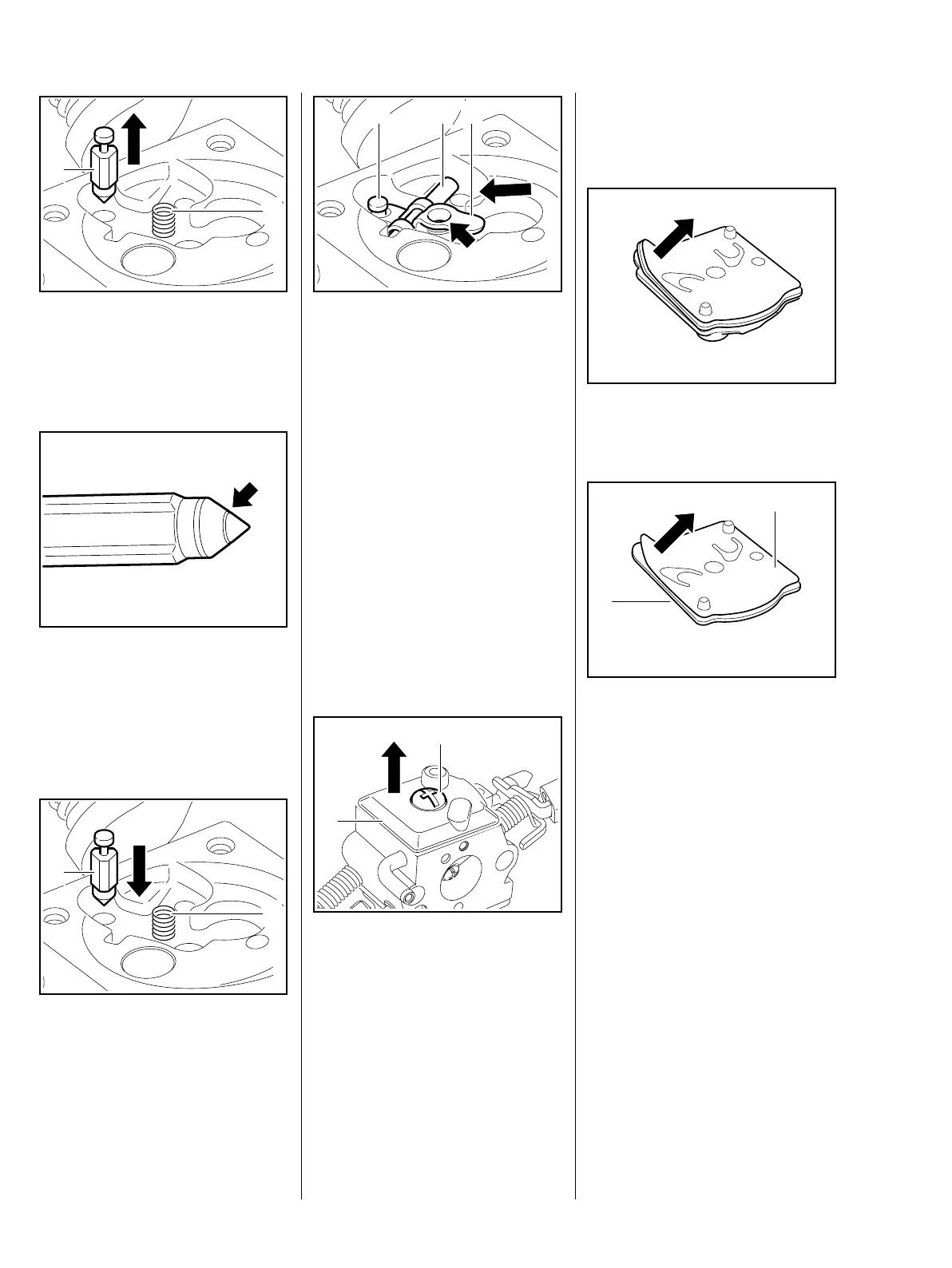

: Take out the screw (1).

– Remove the end cover (2).

0001RA364 TG

1 2 3

0001RA366 TG

1

2

If the gasket and pump diaphragm

are stuck to the carburetor, remove

them very carefully.

: Carefully remove the pump

diaphragm with gasket.

: Carefully separate the pump

diaphragm (2) and gasket (1).

The diaphragm material is

subjected to continuous alternating

stresses and eventually shows

signs of fatigue, i.e. the diaphragm

distorts and swells and has to be

replaced.

– Check the pump diaphragm for

signs of damage and wear. Install

a new gasket.

– Check fuel strainer for

contamination and damage.

Clean or replace if necessary.

0001RA367 TG

0001RA368 TG

1

2

Loading...

Loading...