Theory of Operation Model 200E Instruction Manual

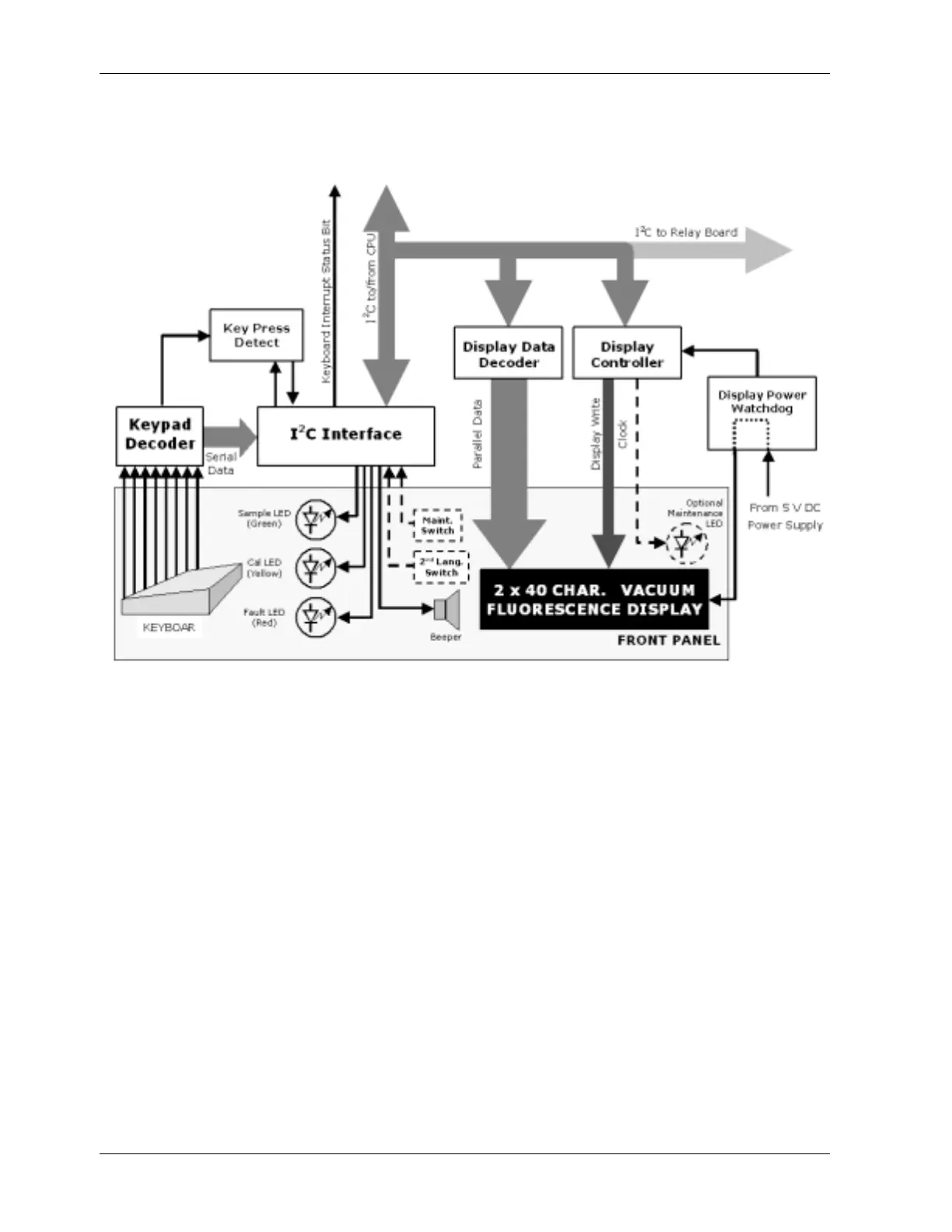

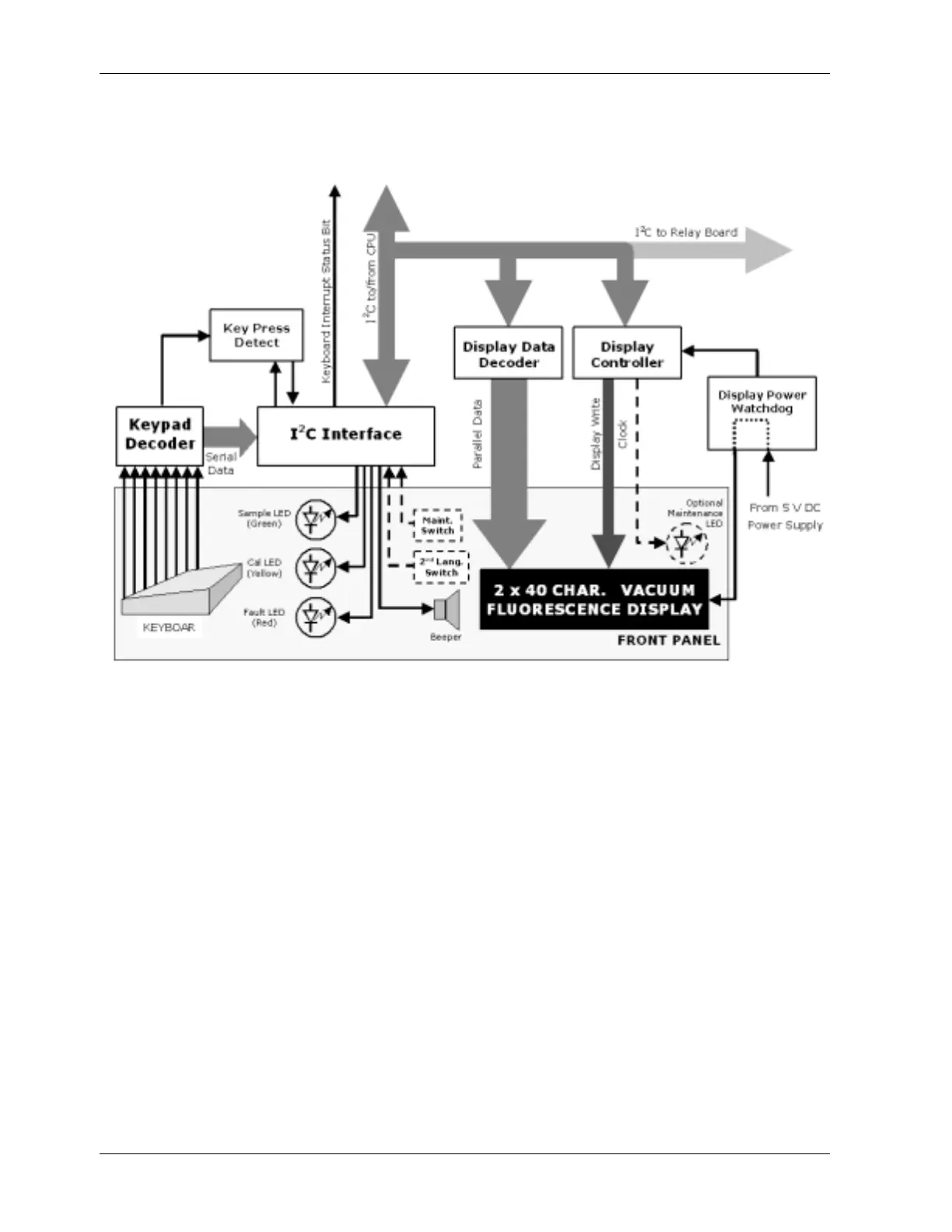

is handle by the instrument’s I

2

C bus. The CPU controls the clock signal and determines

when the various devices on the bus are allowed to talk or required to listen. Data packets

are labeled with addresses that identify for which device the information is intended.

Figure 10-17: Keyboard and Display Interface Block Diagram

10.4. Software Operation

The M200E NO

X

analyzer’s core module is a high performance, 386-based microcomputer

running a version of DOS. On top of the DOS shell, special software developed by T-API

interprets user commands from various interfaces, performs procedures and tasks, stores

data in the CPU’s memory devices and calculates the concentrations of NO

X

in the sample

gas. Figure 10-18 shows a block diagram of this software functionality.

10.4.1. Adaptive Filter

The M200E NO

X

analyzer software processes sample gas concentration data through a built-

in adaptive filter. Unlike other analyzers that average the output signal over a fixed time

period, the M200E averages over a defined number of samples, with samples being about 8

seconds apart (reflecting the switching time of 4 s each for NO and NO

X

). This technique is

known as boxcar filtering. During operation, the software may automatically switch between

two different filters lengths based on the conditions at hand.

During constant or nearly constant concentrations, the software, by default, computes an

average of the last 42 samples, or approximately 5.6 minutes. This provides smooth and

184 044100102 Rev A

Loading...

Loading...