4

Note:

US Patent no. 4,734,872

Temperature Range:

1,3

-80° to +225°C (60 Hz System)

-75

° to +225°C (50 Hz System)

Typical Temperature Transition Rate (air)

1,2

-55° to +125°C: approx. 10 seconds or less

2

+125° to -55°C: approx. 10 seconds or less

2

System air flow output 2.4 l/s to 9 l/s (5 to 18 scfm) CONTINUOUS

T

emperature accuracy 1.0°C (when calibrated against NIST transfer

standard)

Temperature set, display and resolution ± 0.1°C

Temperature Control:

DUT Sensor Ports Internal diode, Type T and Type K Thermocouple and

100 ohm Platinum R

TD

DUT Control Control to within ± 0.1°C; SELF-TUNING available in DUT Control

Remote interface ports IEEE-488, RS232C Serial, and Start Test/End of Test/Stop on

First Fail (ST/ET/SFF) and Ethernet

1

Note: Ultimate low temperature and system performance may vary under operating conditions less than or greater than nominal.

2

Note: Transition performed under nominal operating conditions.

3

Note: Low temperature extremes may be achieved at reduced airflow rates

TP04300A

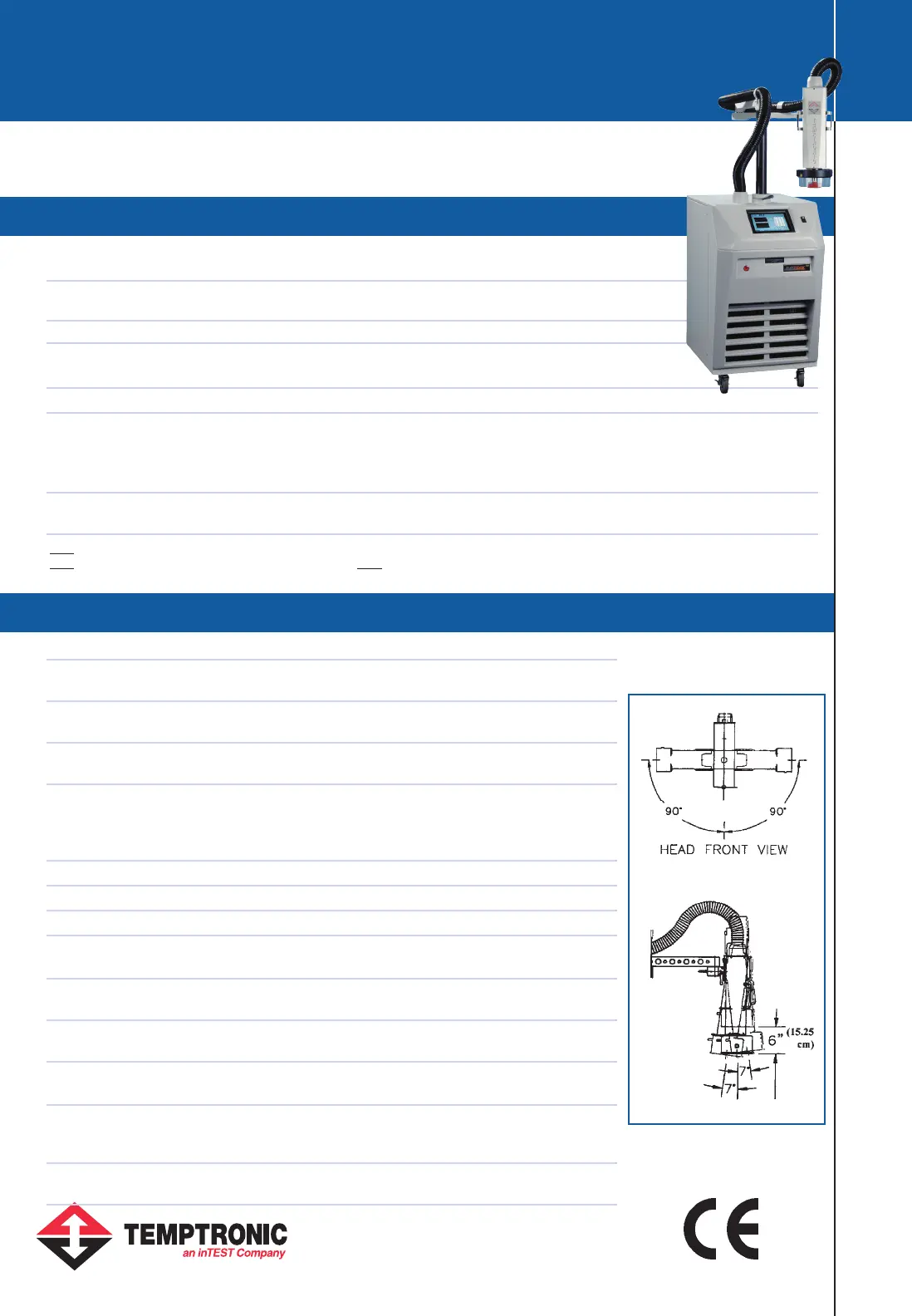

Model TP04300A ThermoStream

®

System Specifications

USER FEATURES

P

art No.

SL10270 R/E

Mobile Temperature System for testing components, parts, hybrids, modules,

subassemblies and printed circuit boards at precise temperature.

TEMPERATURE PERFORMANCE AND AIRFLOW CAPACITY

Modes of operation Two: Operator Mode and Cycling Mode

Test set-up configurations In Cycling Mode, an unlimited quantity

may be created; save to hard disk/diskettes

Ramp/soak/cycle configurations In Cycling Mode, up to 18 sequences per test

set-up; table is displayed on-screen

Program and data storage Data logging and program files may be stored

on the hard drive or to a 3.5" floppy diskette

External Device Ports Ports are located on the front of the system for

connecting a mouse, printer and keyboard; plus a USB

Port (for connecting a USB memory stick, USB mass

storage drive, USB printer, etc.)

On-scr

een help

Included for both Cycling and Operator

’

s Modes

DUT temperatur

e contr

ol

Patented

4

Dual Loop T

emperatur

e Contr

ol

Status indicators On-screen and remote I/O

Pur

ge flow tester inter

face

Dr

y air pur

ge pr

otects tester electr

onics

protection from condensation

Purge flow capacity 0.25 to 1.5 liters per second (0.5 to 3 scfm) airflow,

manually adjustable

Calibration

Automated, simplified and accurate for all

airflows and DUT types

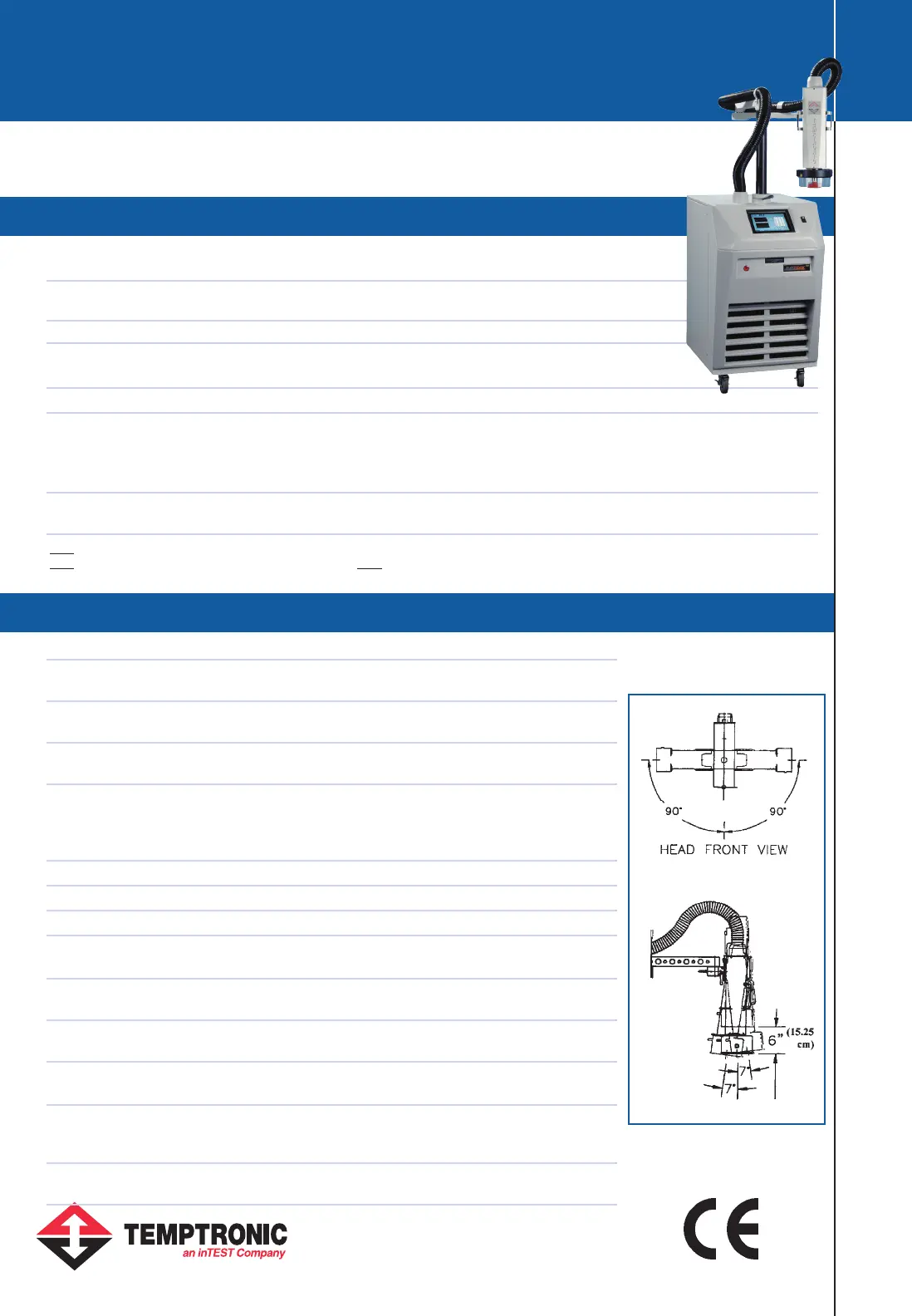

Thermal head raising and lowering Pneumatic control on thermal head,

operated manually or via r

emote inter

face

Head positioner movement Manual locking (4 locks), 360° head rotation; head

can be manually pivoted, turned, tilted and vertically

swung for ease of interface at tester site.

Manipulator (arm) movement Motorized raising and lowering of arm;

330° positioning range around the base unit

Loading...

Loading...