. . . . .

PREPARATION FOR USE

Non-Standard Thermocouples

TP04300 Series Interface & Applications Manual 2-41

Non-Standard Thermocouples

Introduction Proper thermocouple to DUT contact is essential to insure accurate temperature sensing.

If the techniques given above (how to use the factory supplied socket/fixture(s) to attach Type

T, Type K, RTD/Diode sensors) are considered "standard" thermocouple and "standard"

sensor to DUT attaching techniques, then below are offered "non-standard" or "alternate"

techniques: first, how to construct a thermocouple; second, how to attach it.

Note: to enable testing, a socket/fixture must still be used, to apply power to the DUT circuits.

To properly construct a Type T thermocouple:

1. Use a small gauge (#26, #28, #30, or #36 gauge) teflon or kapton coated copper-constan-

tan thermocouple wire.

2. Using wire thicker than #36 gauge (0.005 inch / 0.013 mm) will conduct excessive heat

between the test specimen DUT and the ambient, resulting in inaccurate temperature mea-

surements.

3. Make the thermocouple junction as small as possible.

To properly attach a thermocouple, using alternate techniques:

1. Review the Sensor Interface Guidelines, page 2-33.

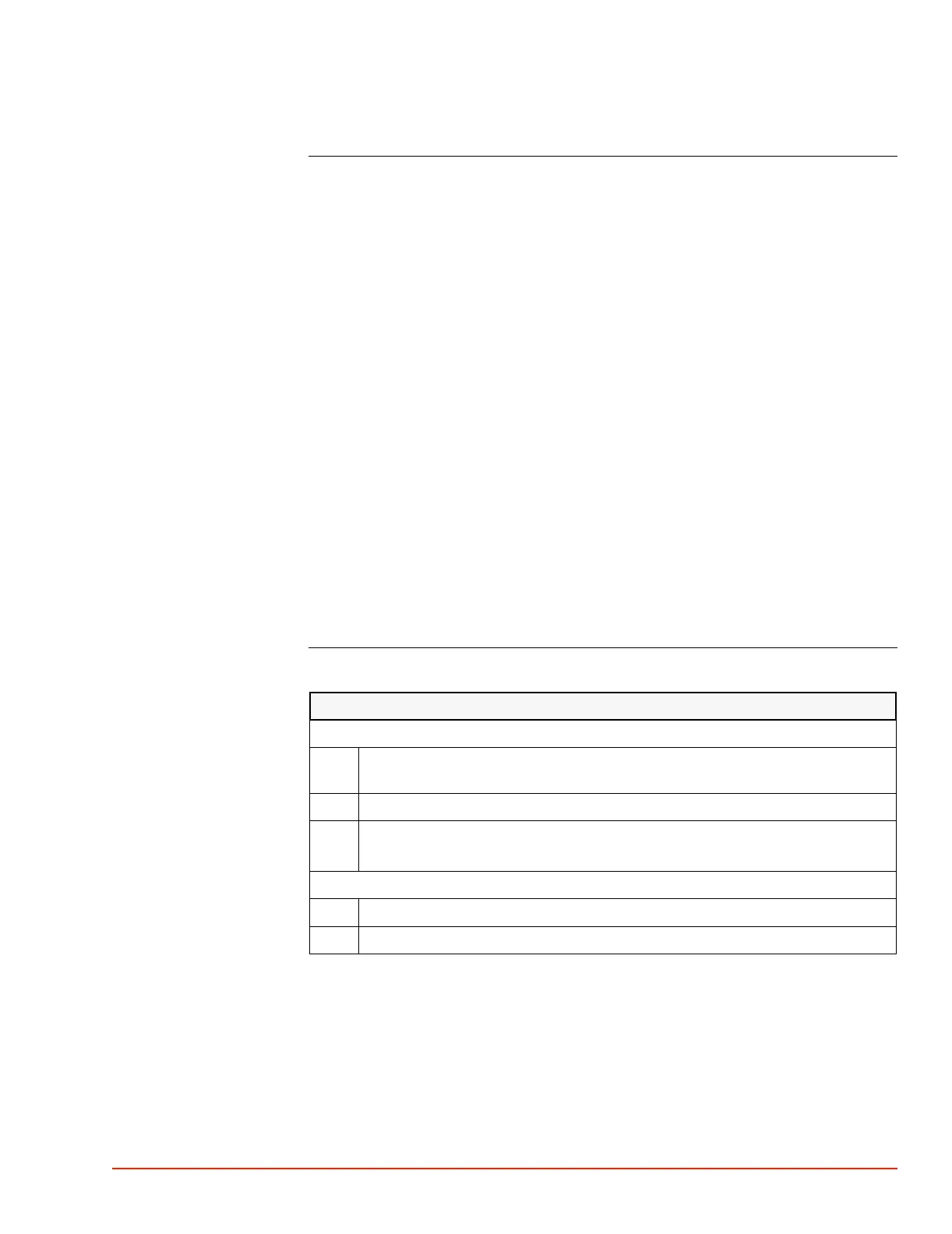

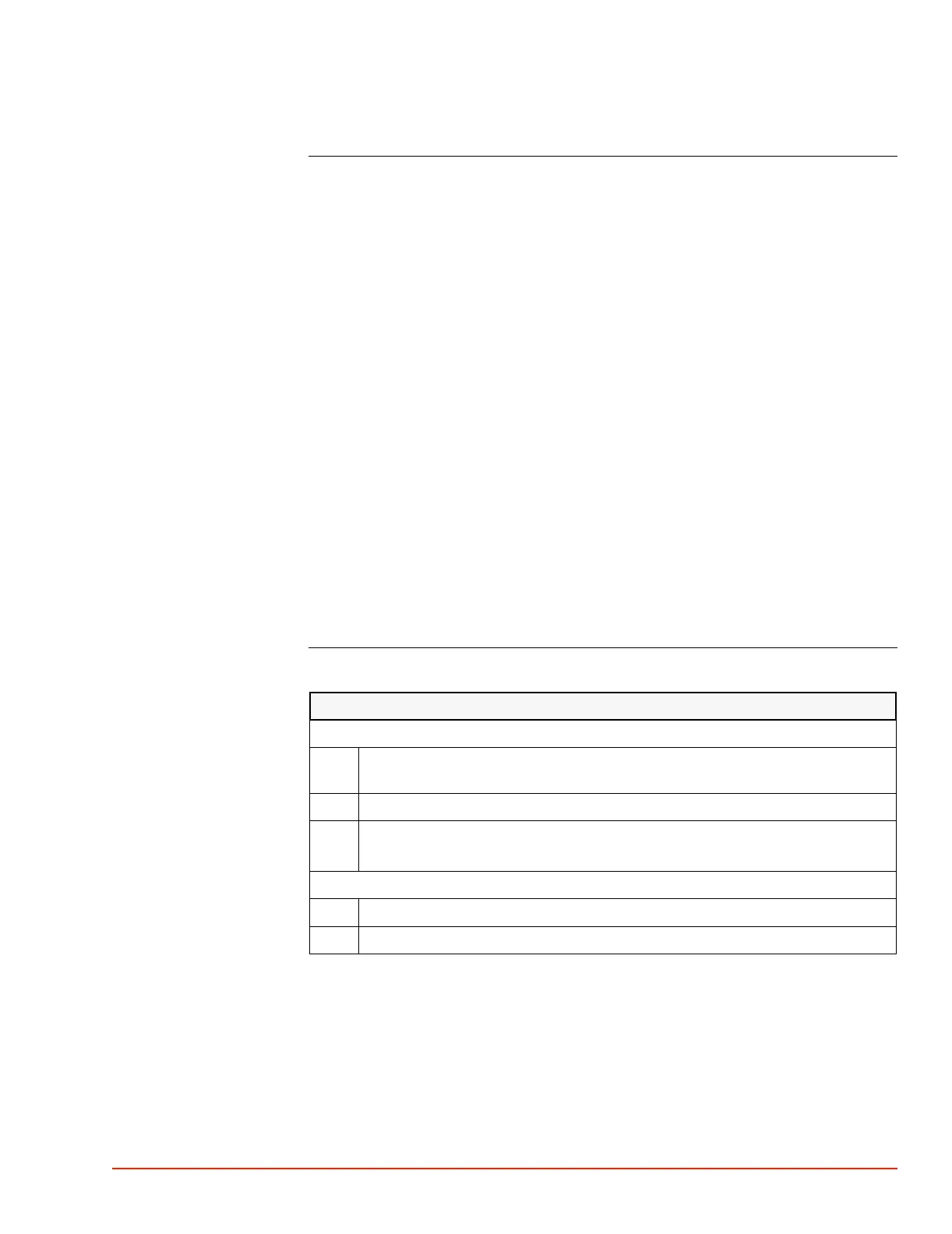

2. Follow the table and illustration below.

Alternate

Techniques

to Attach

Thermocouples

Alternate Techniques to Attach Thermocouples

SOLDERED ATTACHMENT

A UNSATISFACTORY: Sensor only contacts solder; no direct sensor to DUT

contact

B BETTER: Sensor directly contacts DUT, but sensor wire is exposed to ambient air

C BEST: Both sensor junction and sensor wire directly contact DUT;

sensor wire to DUT contact should be at least 30 times diameter of sensor wire

UNSOLDERED ATTACHMENT

1 THIN COPPER PLATE: attached to DUT with thin film of thermal grease

2 ADHESIVE BACKED: sensor "sticks on" to DUT with adhesive

Loading...

Loading...