Description

28.03.2022 33 / 112

4.5 Procedure of a tightness test

A test may consist of several tests

If a test is performed with multiple tests, the following procedure is

repeated.

Determining the initial value

After starting the test, the sensor head is moved into position and the

starting value of the deformation is set to zero.

Build up pressure and record the deformation behaviour of

the watch housing

The test pressure is built up in the test chamber. In order to compensate

for pressure losses caused by the heating of the air, the test pressure is

continuously regulated during the measurement.

The deformation behaviour of the watch is continuously recorded

during pressure build-up and automatically included in the evaluation

algorithm.

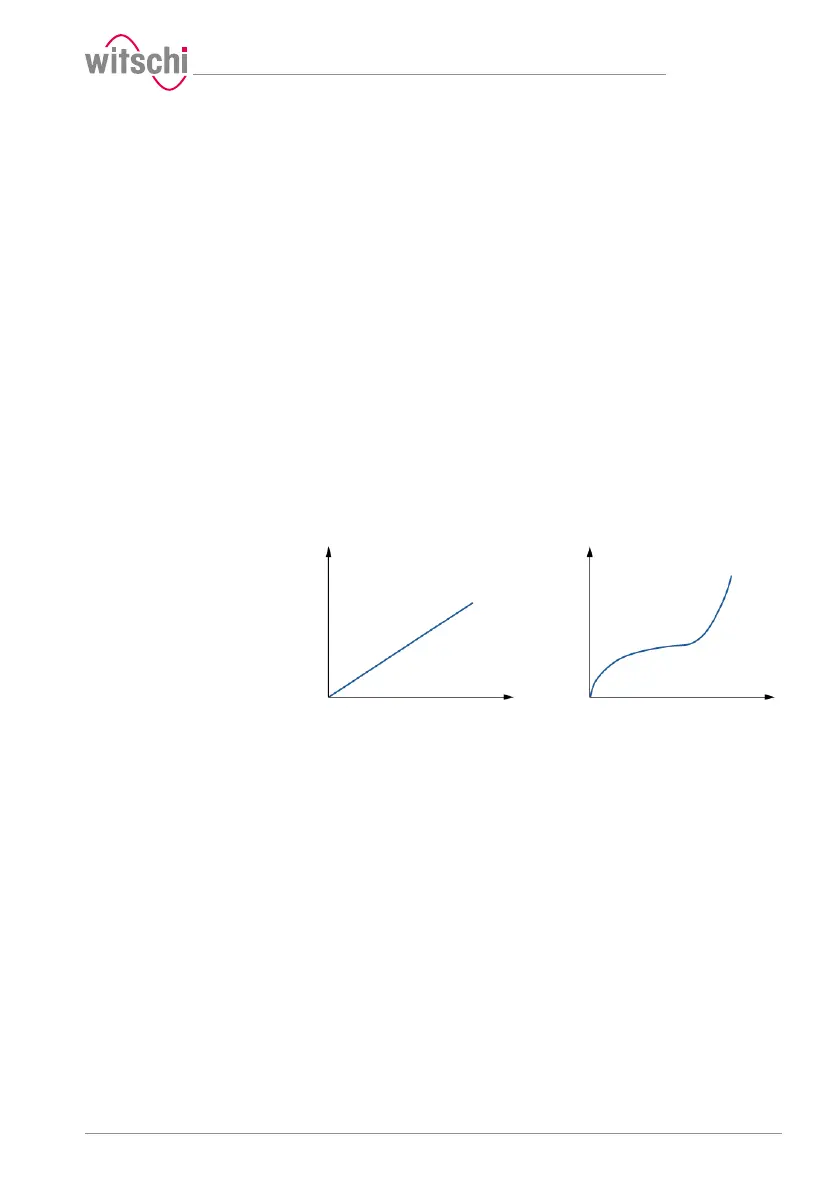

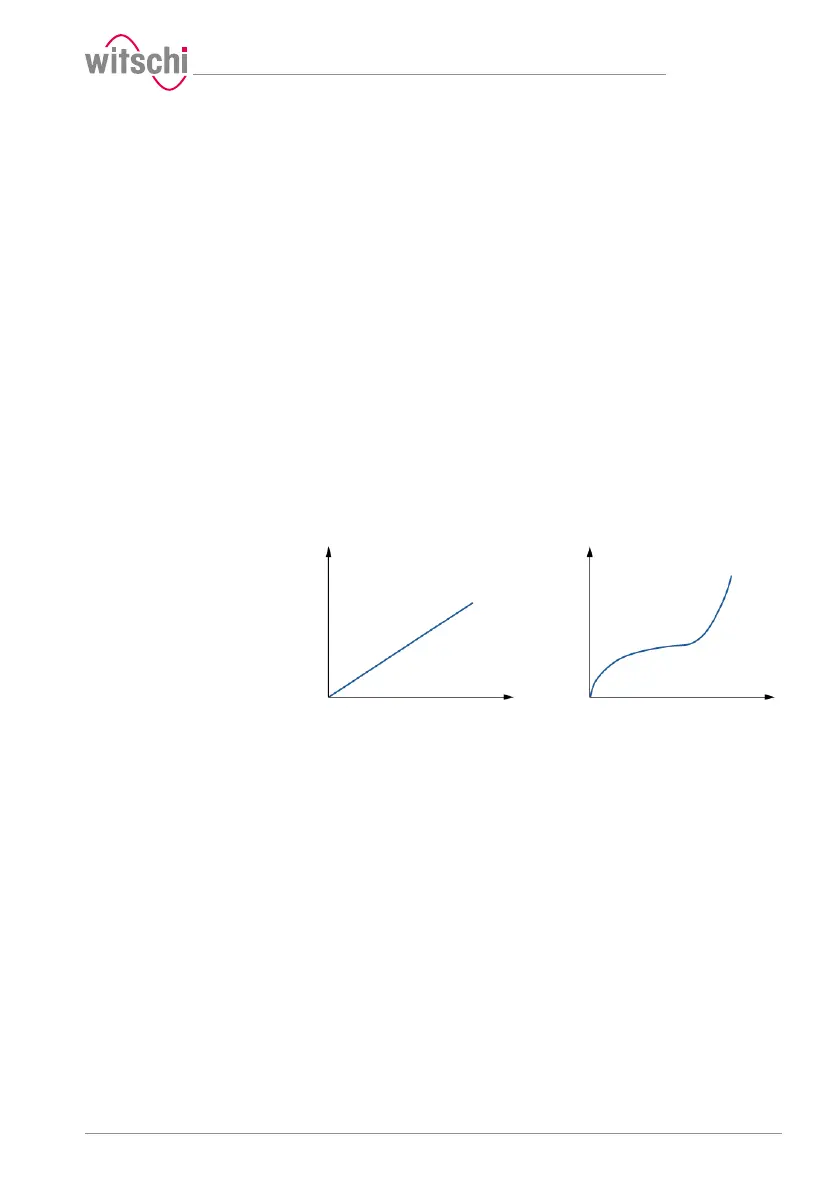

Deformation Deformation

Test pressure Test pressure

Linear deformation behaviour Non-linear deformation

behaviour

Automatic measuring time

The ProofMaster has a new evaluation algorithm which detects elastic

deformation of watches and automatically compensates them.

In the standard setting, the ProofMaster automatically determines the

required measuring time for each measurement. The software continues

the measurement until a meaningful result is obtained.

The measurement time for a simple OK/not OK statement is shorter

than the output of a precise leak rate. It should also be noted that

smaller limits lead to longer measurement times. The maximum time per

test pressure is limited to 300 seconds with automatic measuring time.

For best results in terms of precision and test duration, we recommend

the use of the automatic measurement time.

Loading...

Loading...