Description

28.03.2022 29 / 112

The pressure is built up by means of a compressor connected to the

device inside the test chamber 2. The vacuum is generated by a Venturi

valve integrated in the device and the connected compressor.

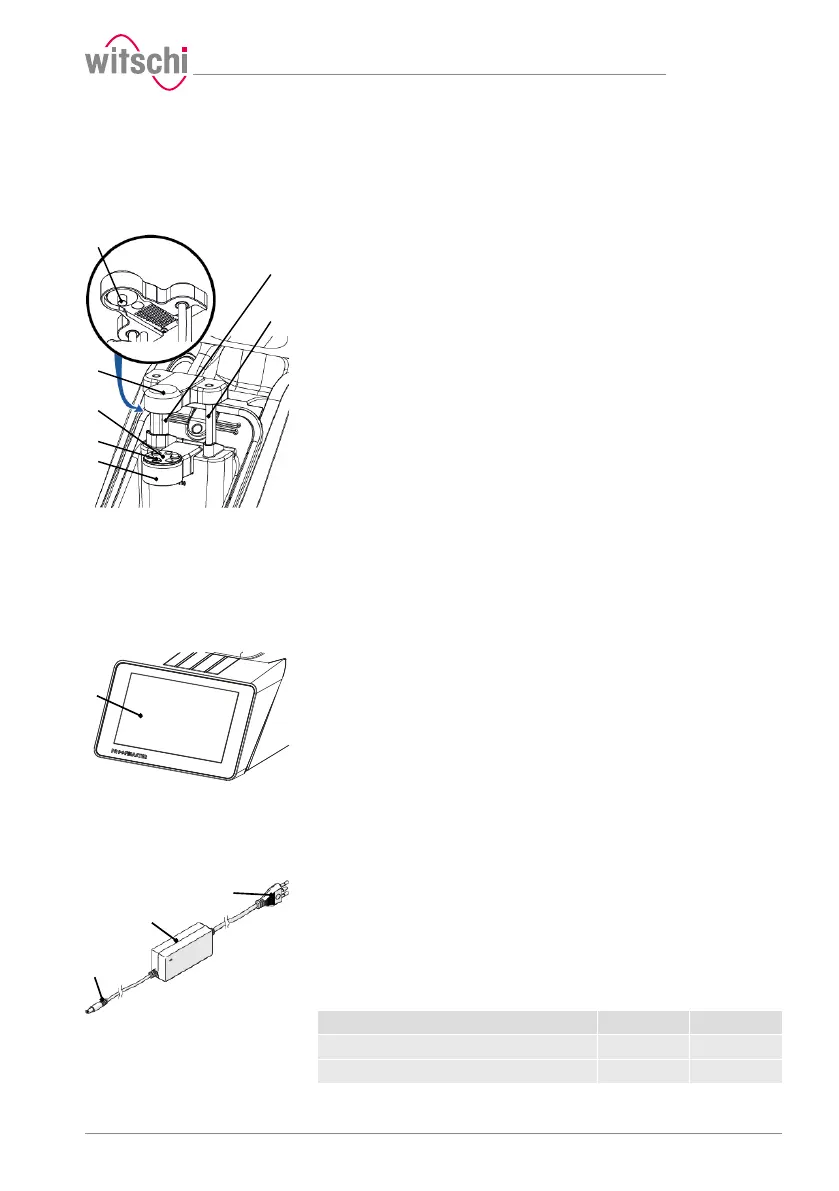

Deformation sensor

1 Measuring probe

2 Sensor head

3 Scratch Protect

4 Support points

5 Support table

6 Sensor guides

7 Driving rods

The deformation sensor makes it possible to measure the deformation

of the watch. During the test, the watch is stabilised by the three

support points 4 that are integrated in the support table 5. If a small

watch is being tested, the Scratch Protect 3 can be removed and the

watch support can be placed on it. The sensor head 2 with the

measuring probe 1 is located on the watch glass during the test and

can thus measure how strongly the watch housing expands or

contracts.

The sensor head 2 is raised or lowered automatically to the watch by

the drive rods 7 when the bell cover opens or closes.

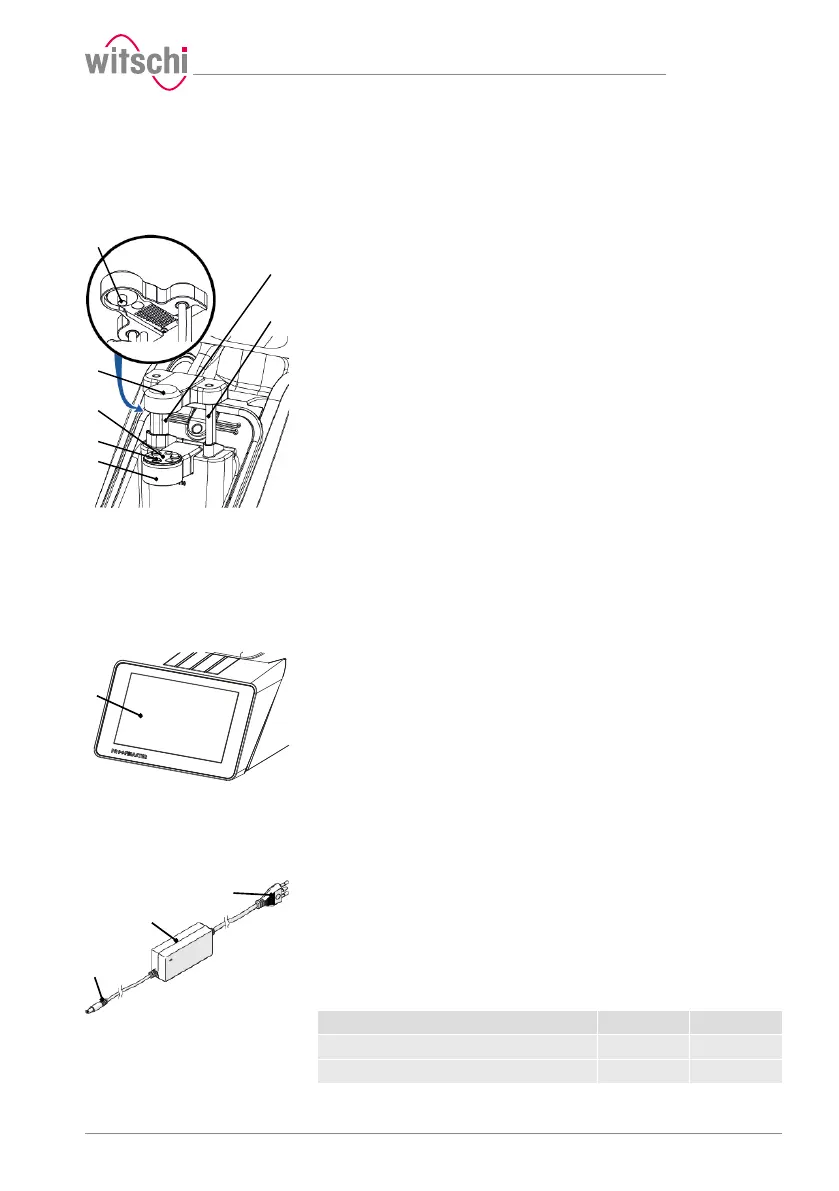

Control and display

element

1 Touchscreen

Using the touchscreen, it is possible to navigate through the menus and

edit the test settings. It also shows the progress and results of the test.

4.2 Included accessories

Power supply unit

1 Power cable (country-specific)

2 Transformer

3 Power connection (on device)

Item no.: JA01-PSD60E120K3

The ProofMaster is connected to the power supply using the power

supply unit with the following key figures:

Description Unit Value

Input voltage VAC 100 to 240

Input current A 1.5

Loading...

Loading...