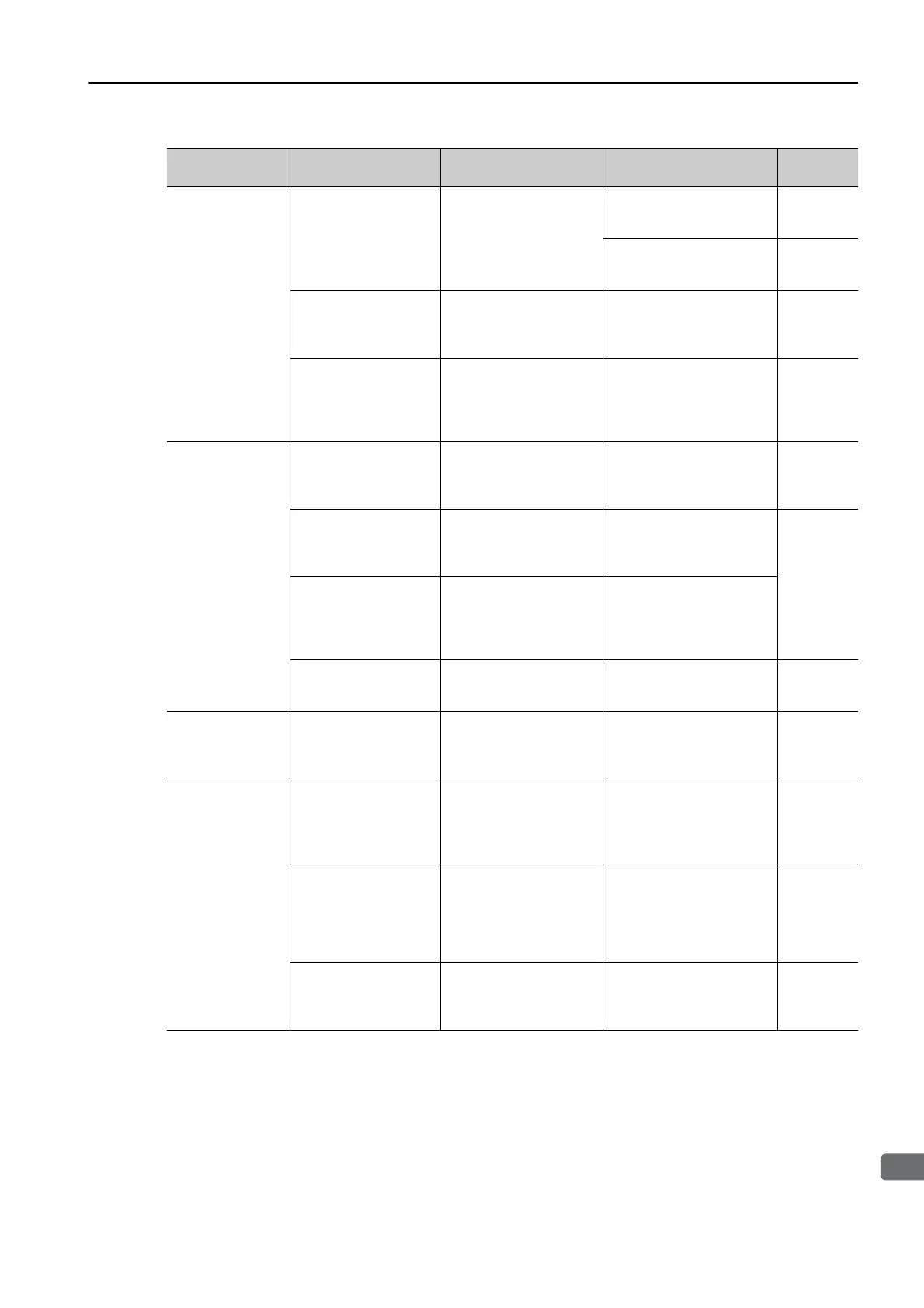

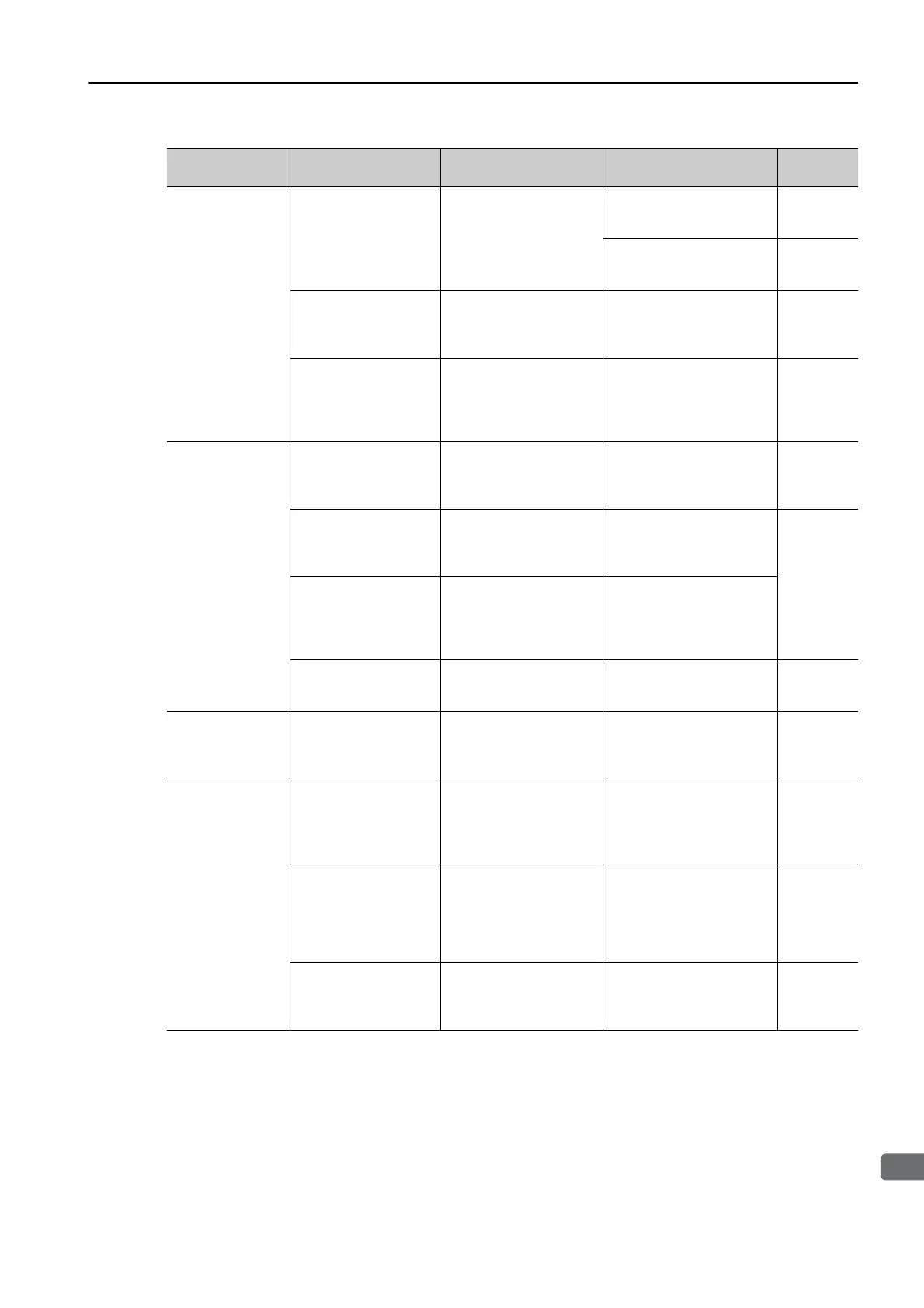

6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-15

A.50D:

Position Devia-

tion Between

Axes Overflow

Alarm

Twisting of mechani-

cal parts has occurred

between axes A and

B.

Check the position

deviation between the

axes.

Resolve the twisting of

mechanical parts between

the axes.

–

Set the Position Correc-

tion Table to appropriate

values.

page 3-7

Axis A and axis B are

not synchronized with

the reference.

Check the reference

position for axis A and

axis B.

The host controller should

command the system to

synchronize operation of

axis A and axis B.

–

Pn66A (Position Devi-

ation Between Axes

Overflow Alarm Level)

is low for the operat-

ing conditions.

Check if Pn66A (Posi-

tion Deviation Between

Axes Overflow Alarm

Level) is appropriate.

Set Pn66A to an appropri-

ate value.

page 5-3

A.510:

Overspeed

(The motor

exceeded the

maximum speed.)

The order of phases

U, V, and W in the

motor wiring is not

correct.

Check the wiring of the

Servomotor.

Make sure that the Servo-

motor is correctly wired.

–

A reference value that

exceeded the over-

speed detection level

was input.

Check the input refer-

ence.

Reduce the reference

value. Or, adjust the gain.

−

The motor exceeded

the maximum speed.

Check the waveform of

the motor speed.

Reduce the speed refer-

ence input gain and

adjust the servo gain. Or,

reconsider the operating

conditions.

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the

SERVOPACK.

–

A.51A:

Synchronized

Stopping Over-

speed Alarm

The axis undergoing

synchronized stop-

ping was accelerating.

Check the feedback

speed of the axis under-

going synchronized

stopping.

Remove the cause of

acceleration for the axis

undergoing synchronized

stopping.

–

A.520:

Vibration Alarm

Abnormal oscillation

was detected in the

motor speed.

Check for abnormal

motor noise, and check

the speed and torque

waveforms during oper-

ation.

Reduce the motor speed.

Or, reduce the setting of

Pn100 (Speed Loop

Gain).

*1

The setting of Pn103

(Moment of Inertia

Ratio) is greater than

the actual moment of

inertia or was greatly

changed.

Check the moment of

inertia ratio or mass

ratio.

Set Pn103 (Moment of

Inertia Ratio) to an appro-

priate value.

*1

The vibration detec-

tion level (Pn312 or

Pn384) is not suitable.

Check that the vibra-

tion detection level

(Pn312 or Pn384) is

suitable.

Set a suitable vibration

detection level (Pn312 or

Pn384).

*1

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...