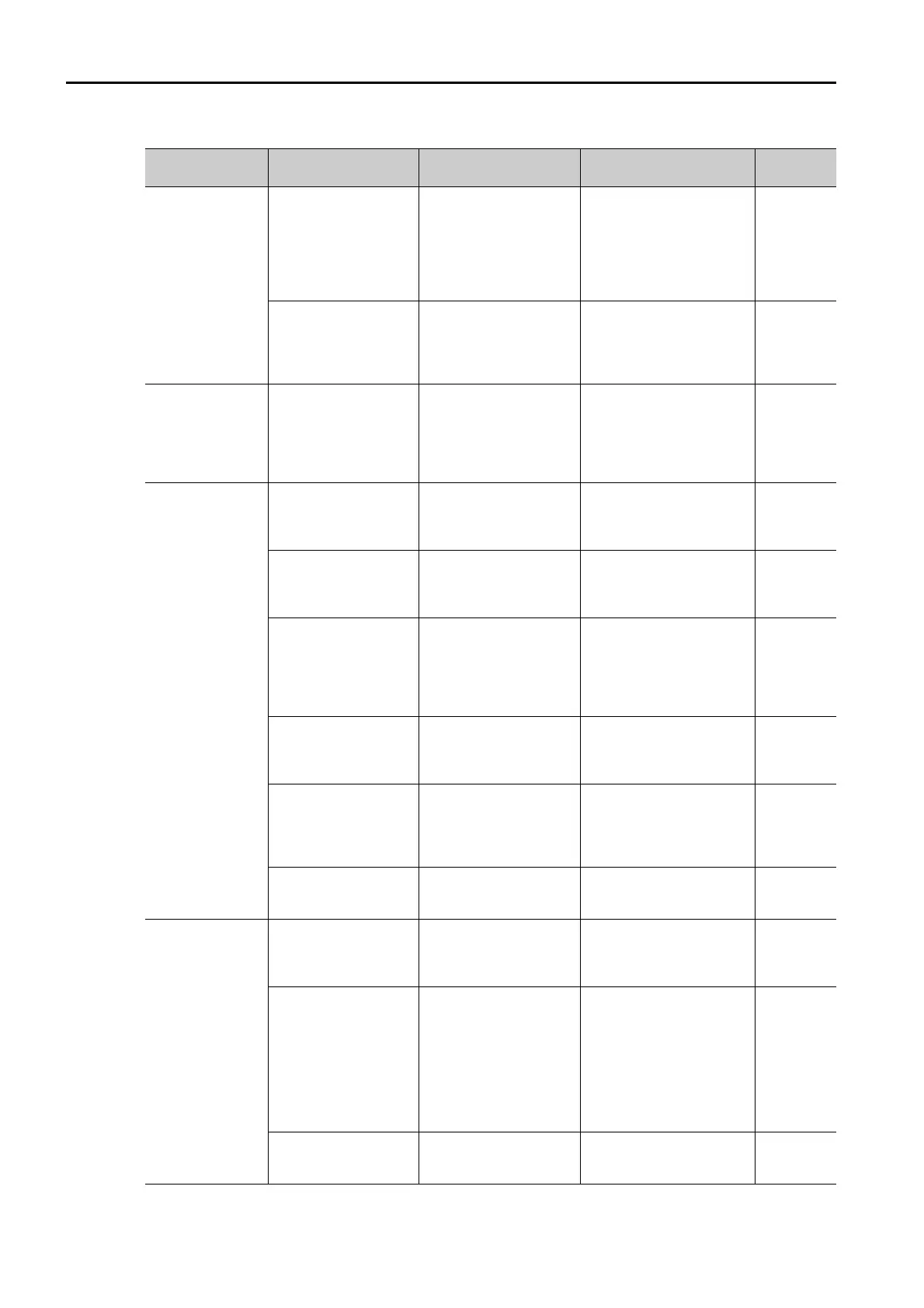

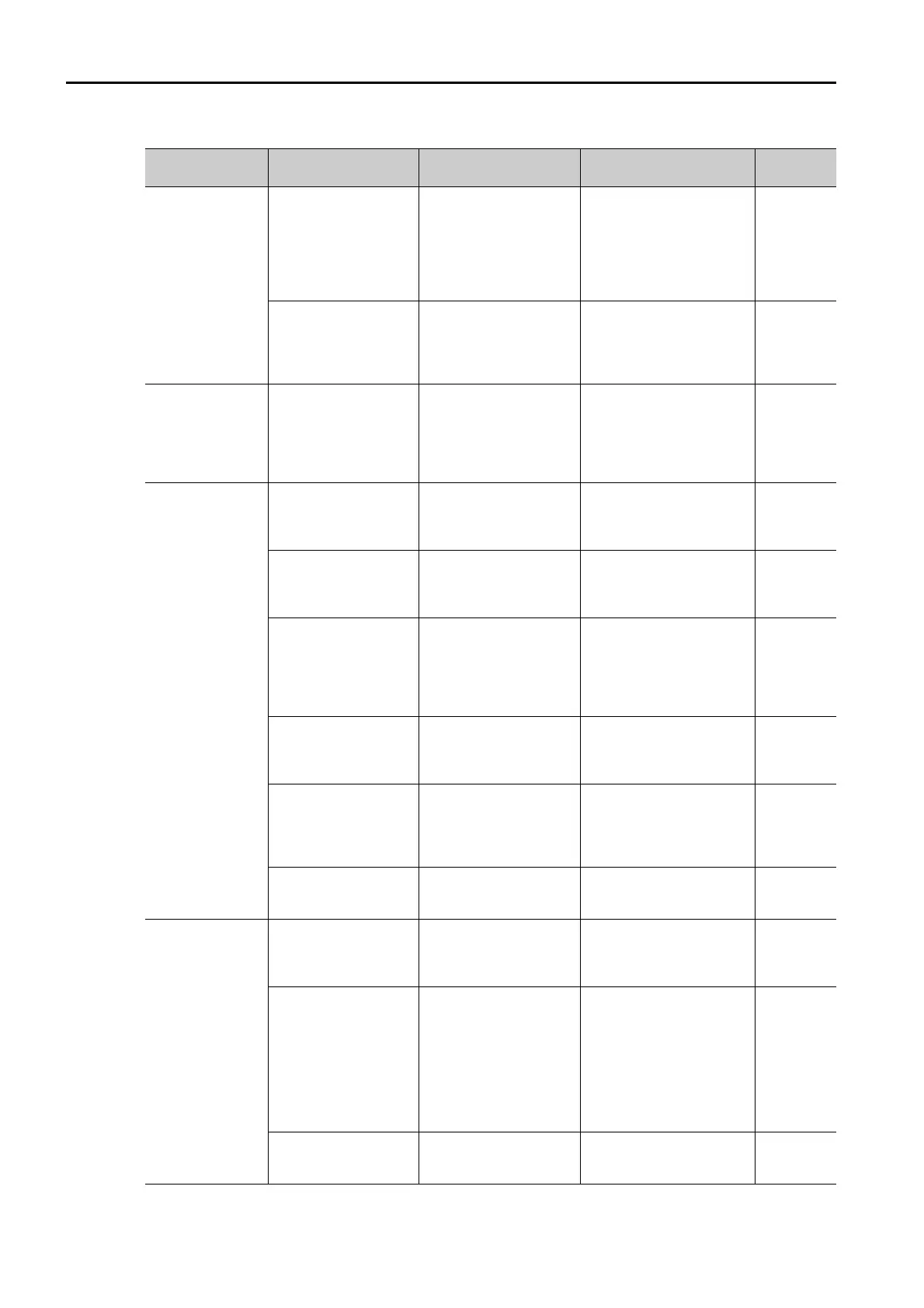

6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-16

A.521:

Autotuning Alarm

(Vibration was

detected while

executing the

custom tuning,

Easy FFT, or the

tuning-less func-

tion.)

The Servomotor

vibrated considerably

while performing the

tuning-less function.

Check the waveform of

the motor speed.

Reduce the load so that

the moment of inertia ratio

is within the allowable

value. Or increase the

load level or reduce the

rigidity level in the tuning-

less level settings.

*1

The Servomotor

vibrated considerably

while performing cus-

tom tuning or Easy

FFT.

Check the waveform of

the motor speed.

Check the operating pro-

cedure of corresponding

function and implement

corrections.

*1

A.550:

Maximum Speed

Setting Error

The setting of Pn385

(Maximum Motor

Speed) is greater than

the maximum speed.

Check the setting of

Pn385, and the upper

limits of the maximum

motor speed setting

and the encoder output

resolution setting.

Set Pn385 to a value that

does not exceed the max-

imum motor speed.

*1

A.710:

Instantaneous

Overload

A.720:

Continuous

Overload

The wiring is not cor-

rect or there is a faulty

contact in the motor

or encoder wiring.

Check the wiring.

Make sure that the Servo-

motor and encoder are

correctly wired.

*1

Operation was per-

formed that exceeded

the overload protec-

tion characteristics.

Check the motor over-

load characteristics and

Run command.

Reconsider the load and

operating conditions. Or,

increase the motor

capacity.

–

An excessive load

was applied during

operation because the

Servomotor was not

driven due to

mechanical problems.

Check the operation

reference and motor

speed.

Correct the mechanical

problem.

–

There is an error in the

setting of Pn282 (Lin-

ear Encoder Scale

Pitch).

Check the setting of

Pn282.

Correct the setting of

Pn282.

*1

There is an error in the

setting of Pn080 =

n.X (Motor

Phase Sequence

Selection).

Check the setting of

Pn080 = n.X.

Set Pn080 = n.X to

an appropriate value.

*1

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the

SERVOPACK.

–

A.730 and A.731:

Dynamic Brake

Overload

(An excessive

power consump-

tion by the

dynamic brake

was detected.)

The Servomotor was

rotated by an external

force.

Check the operation

status.

Implement measures to

ensure that the motor will

not be rotated by an

external force.

–

When the Servomo-

tor was stopped with

the dynamic brake,

the rotational or linear

kinetic energy

exceeded the capac-

ity of the dynamic

brake resistor.

Check the power con-

sumed by the DB resis-

tor to see how

frequently the DB is

being used.

Reconsider the following:

• Reduce the Servomotor

command speed.

• Decrease the moment

of inertia ratio or mass

ratio.

• Reduce the frequency of

stopping with the

dynamic brake.

–

A failure occurred in

the SERVOPACK.

–

The SERVOPACK may be

faulty. Replace the

SERVOPACK.

–

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...