<3. INSTALLATION>

3-2

IM 01E30D01-01EN

(5) Precautions for Use of Liquid Sealing

Compounds

IMPORTANT

Care must be taken in using liquid sealing

compounds on the piping, as it may have a

negativeinuenceontheowindicationsby

owingoutandcoveringthesurfacesofan

electrode or grounding ring. In particular, care

must be taken if a liquid sealing compound is

used in the case of vertical piping.

(6) Service Area

Select locations where there is adequate space to

service installing, wiring, overhauling, etc.

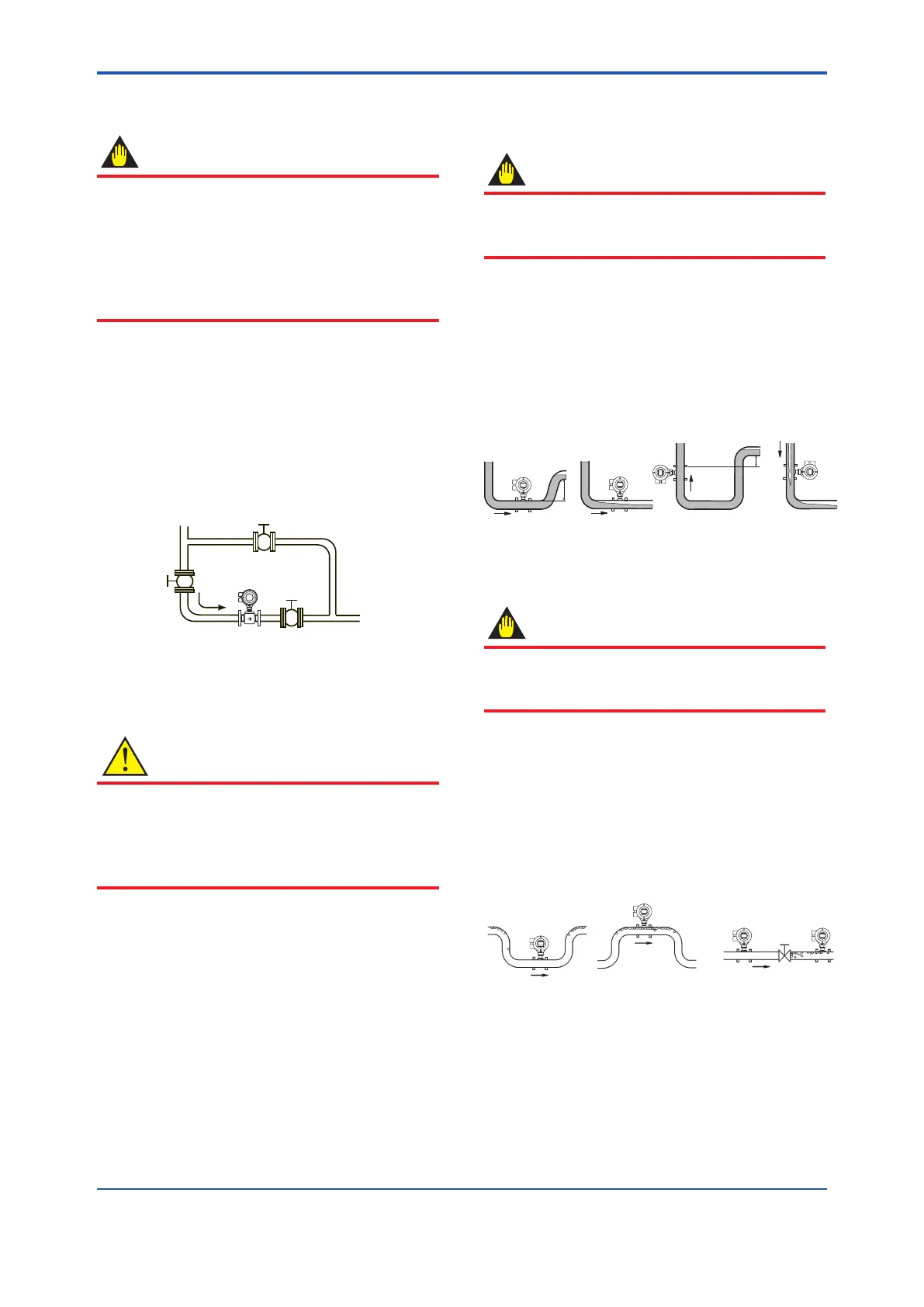

(7) Bypass Line

It is recommended to install a bypass line to facilitate

maintenance and zero adjustment.

Block valve

Figure 3.1.3 Bypass Line

(8) Supporting the Flowmeter

CAUTION

Donotsecuretheowmeterseparatelyto

prevent the vibrations, shocks, and expansion

and contraction forces of the piping from

affectingit.Fixthepipesrst,thensupportthe

owmeterwiththepipes.

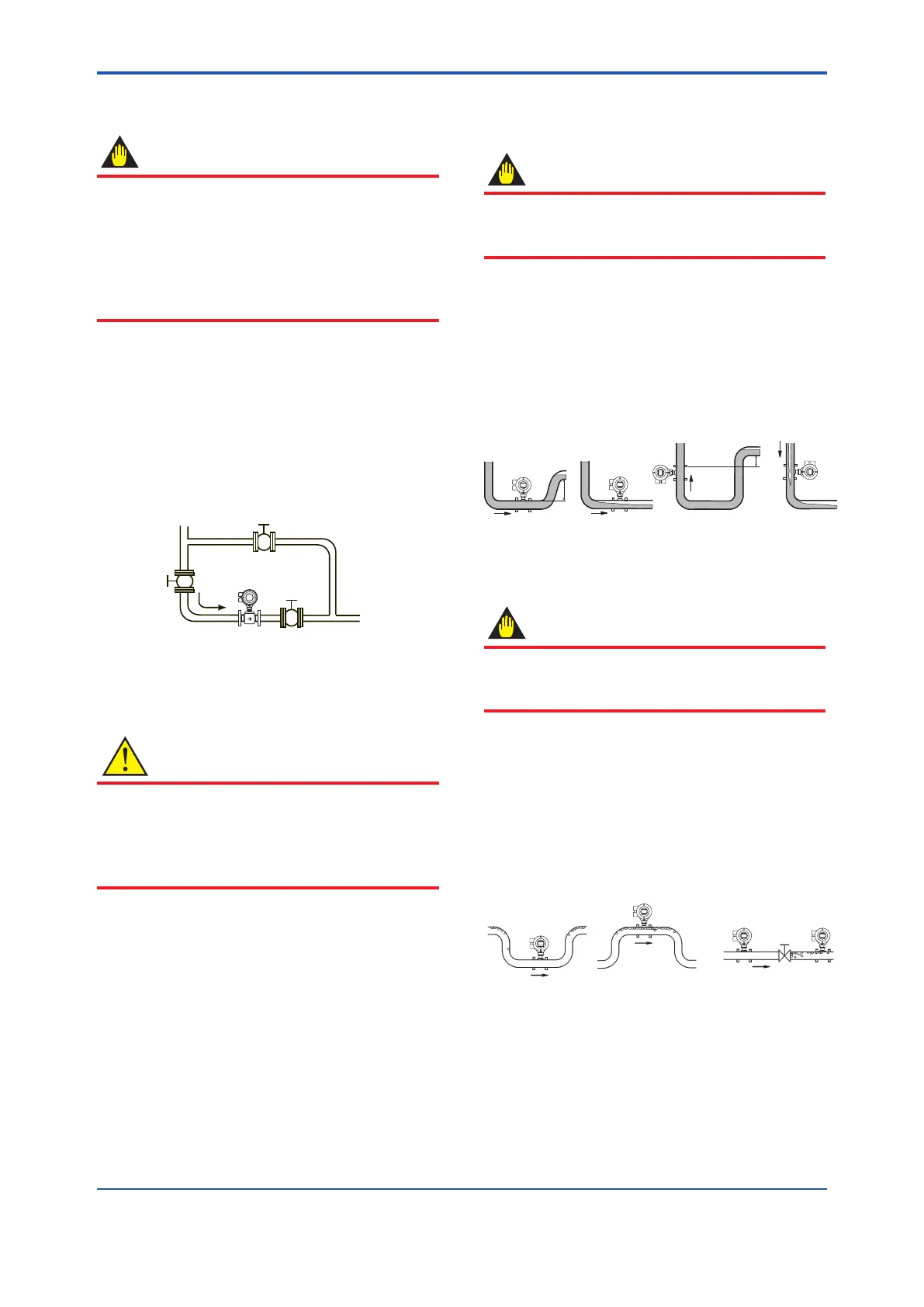

(9) Mounting Positions

• Pipesmustbefullylledwithliquids.

IMPORTANT

Ifthepipeisempty,theoutputuctuatesorthe

ProcessAlarm(SignalOverow)occurs.The

pipemustbefullylledwithliquid.

Piping shall be designed so as to maintain the

interioroftheowtubelledwithuids.

Vertical mounting is effective in such cases as

whenuidstendtoseparateorsolidmattermaybe

precipitated. When employing vertical mounting,

directtheuidsfromthebottomtothetoptoensure

thatthepipesremainfullylled.

(Correct)

(Incorrect)

(Correct)

h

h>0

h>0

h

Figure 3.1.4 Mounting Positions

• Avoidairbubbles.

IMPORTANT

If air bubbles enter a measurement pipe,

owrateindicationsmaybeaffectedand

measurement errors may be caused.

Incaseswhereuidscontainairbubbles,pipingmust

be designed to prevent them from accumulating in

themeasurementpipeofaowtube.

Ifavalveexistsneartheowmeter,trytomountthe

owmeteronthevalve’supstreamsideinorderto

prevent a possible reduction of pressure inside the

pipe, thereby avoiding the possibility of air bubbles.

Valve

(Correct)

(Incorrect)

(Correct)

Figure 3.1.5 Avoiding Air Bubbles

Loading...

Loading...