<11. MAINTENANCE>

11-12

IM 01E30D01-01EN

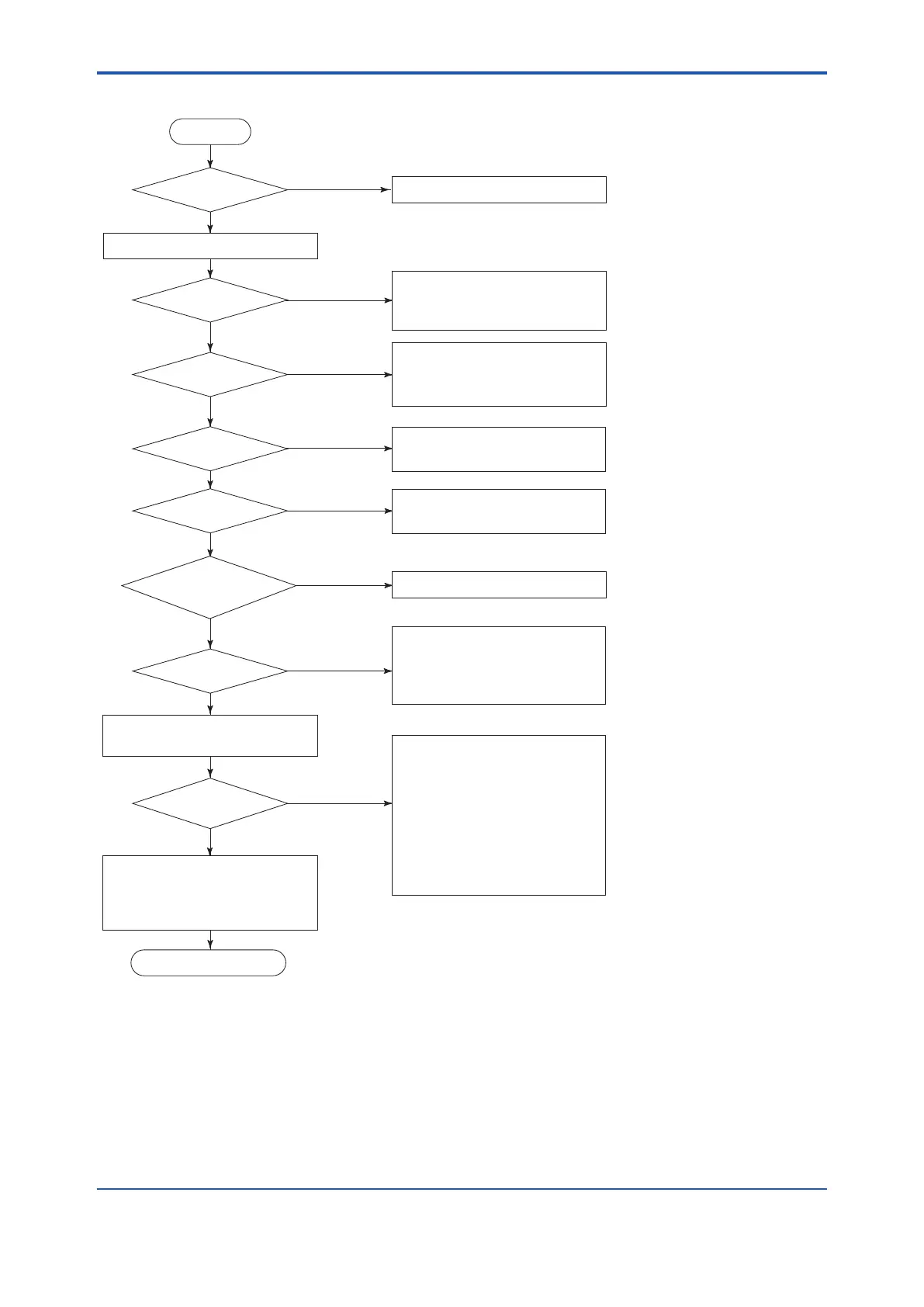

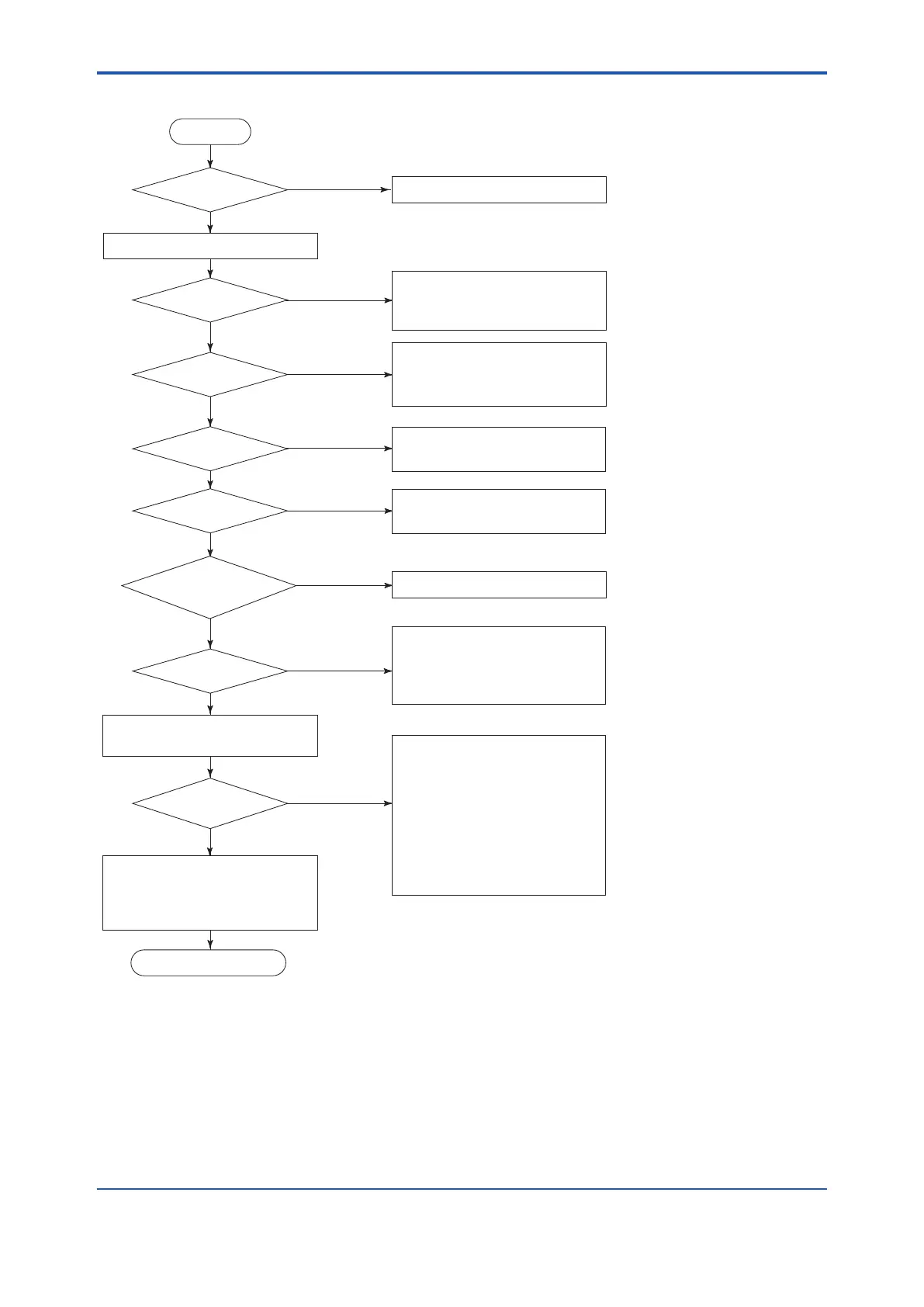

11.7.3 Disagreement Between Indication and Actual Flow

NO

NO

NO

YES

NO

NO

YES

YES

YES

NO

YES

NO

NO

YES

Set the parameters correctly.

Examine the condition of the fluid in the

flowtube, of bubbles, and of grounding.

Execute zero adjustment when the

flowtube is filled completely with fluid and

when the fluid is not moving.

● Change the mounting position or piping

so that the flowtube is

completely filled with fluid.

● Switch to vertical mounting.

Install a defoaming device on the

flowtube’s upstream side.

Completely ground the flowmeter

(Read Section 4.4.)

Use within the specified conductivity range.

Confirm that a valve is located

immediately upstream of the flowtube

(i.e., on the upstream side).

● Remove scales. Especially clean the

electrodes and their vincinity.

● Use a soft brush or cloth to perform

scale removal, and make sure that the

lining is not damaged.

YES

● If any valve located immediately

upstream of the flowtube is used in a

half-open condition, the indication may

be affected by turbulence in the flow.

● Relocate the valve to the downstream

side.

● If the valve must be located on the

upstream side, ensure that the minimum

distance to the flowmeter is 10 times

the flow-tube diameter; alternatively,

use the valve fully open.

START

Are parameters

set correctly?

Is the tube

filled completely with

fluid?

Is the

flowmeter completely

grounded?

Is the

fluid likely to contain

deposits?

Is a valve

located immediately upstream

of the flowtube?

Examine the operation of the converter

using an AM012 calibrator in order to

determine whether the fault lies in the

converter or in the flowtube.

Contact a service center.

Was zero

adjustment carried out

correctly?

Does the fluid

contain bubbles?

YES

Does the

conductivity stay within the

specified range?

Loading...

Loading...