<3. INSTALLATION>

3-10

IM 01E30D01-01EN

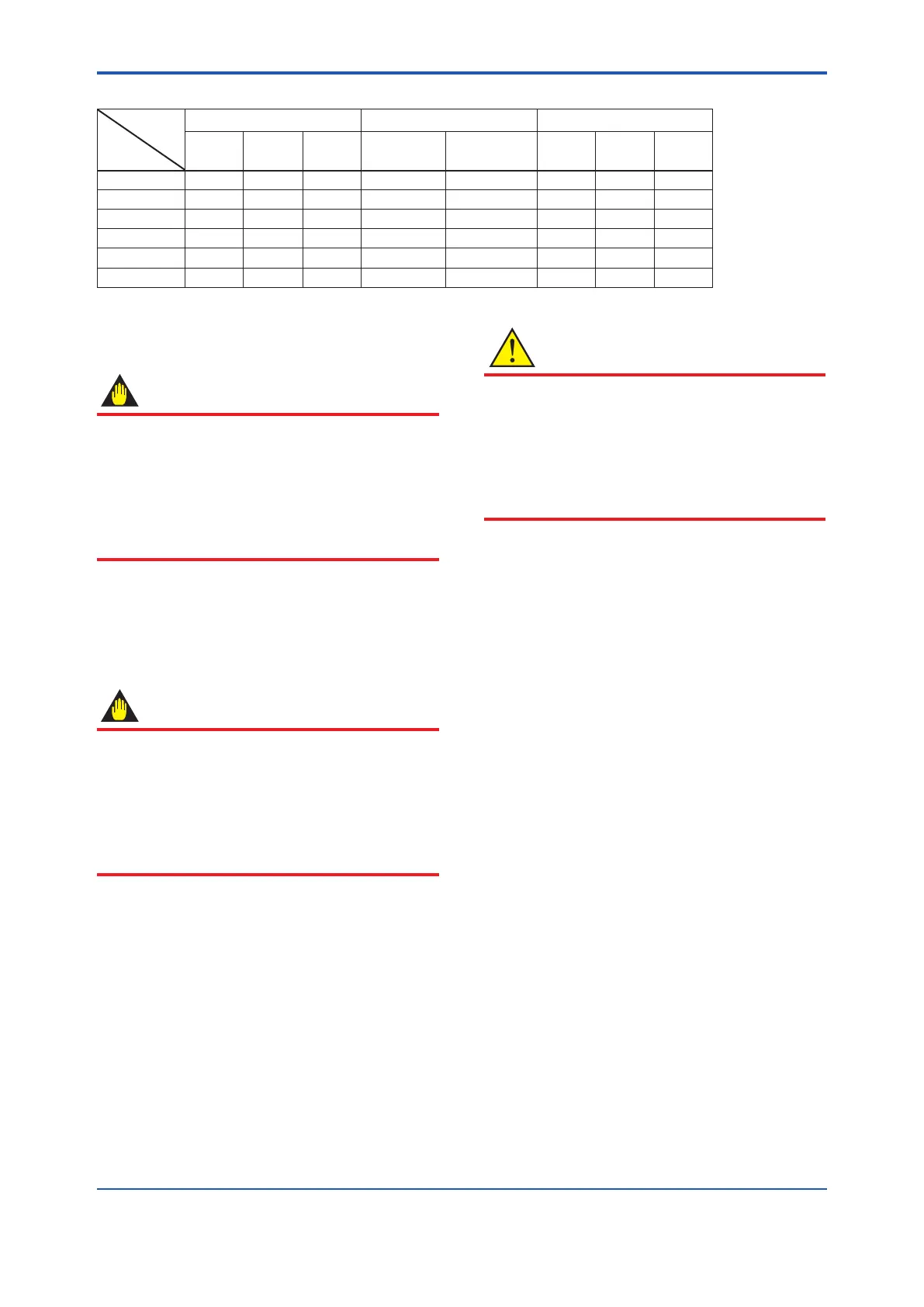

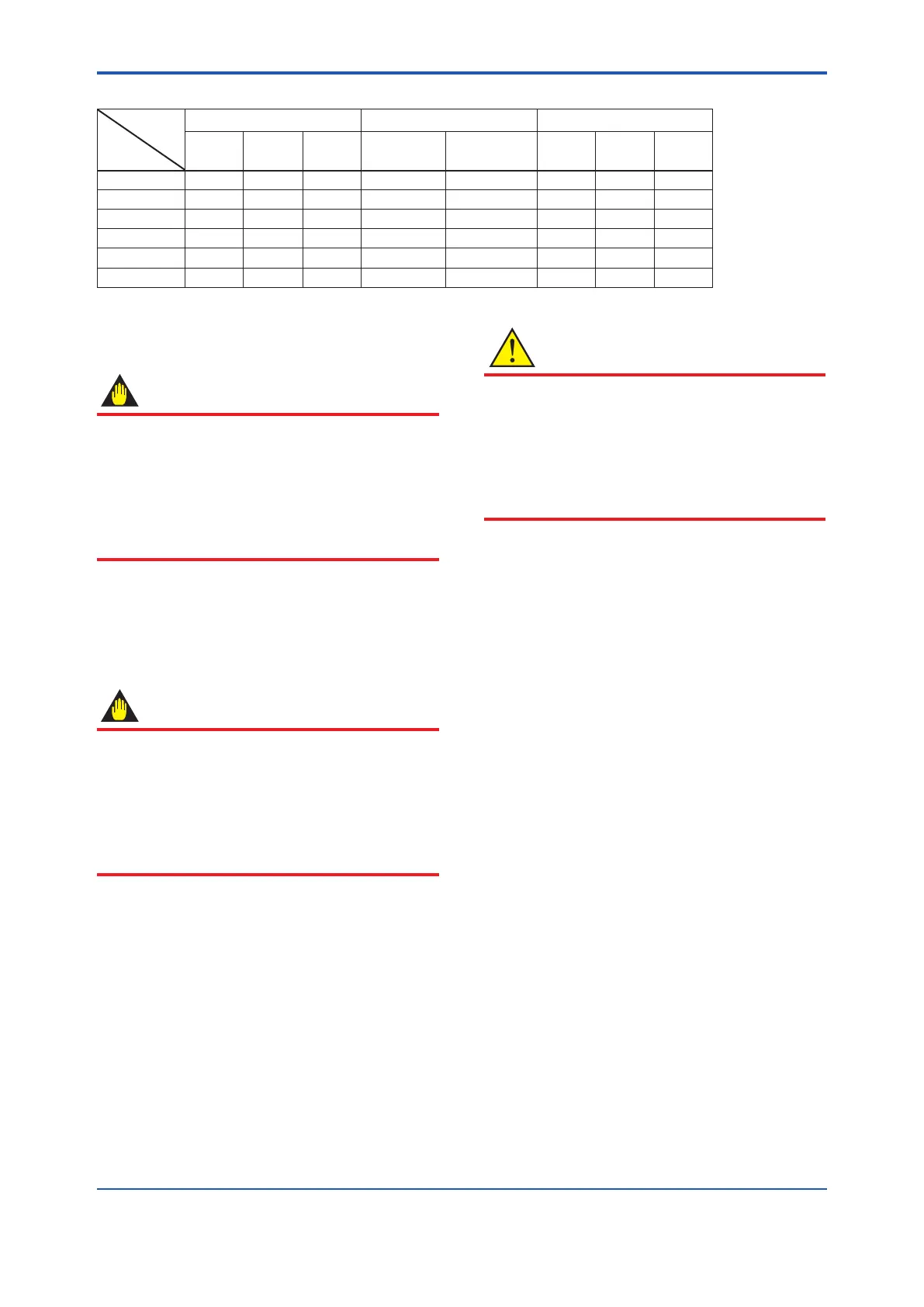

Table3.3.8 CenteringDeviceIdentication(AXRLaylengthcode2,PFAlining)

Flange

ratings

Size

mm (inch)

JIS ANSI DIN

10K 20K

F12

(75M)

150 300 PN10 PN16 PN40

50 (2.0) B B — B F — — F

65 (2.5) B B — B G — F —

80 (3.0) B F H F C — G —

100 (4.0) B F H C H — F —

150 (6.0) C D D C E — C —

200 (8.0) C D D D E C C —

*:Eachcenteringdeviceisengravedwithacharacterasidentication.

3.3.3 Nominal Diameter 25 mm (1.0 in.) to

200 mm (8.0 in.), Flange Type

IMPORTANT

Useboltsandnutsincompliancewiththeange

ratings. Be sure to choose a gasket with inner

and outer diameters that does not protrude

inside the piping (Read Subsection 3.3.4). If the

inner diameter of the gasket is too large, or outer

diameterofthegasketistoosmall,uidleakage

may result.

(1) Mounting Direction

Mounttheowmetersothattheowdirectionofthe

uidtobemeasuredisinlinewiththedirectionof

thearrowmarkontheowmeter.

IMPORTANT

If it is impossible to match the direction of

the arrow mark, the direction of the electrical

connection can be changed. Read Section 11.1

to do this properly.

Incasetheuidbeingmeasuredowsagainst

the arrow direction, read the parameter J20:

Flow Direction in this user’s manual.

(2) Tightening Nuts

Tighten the bolts according to the torque values

for the metal piping in Table 3.3.9. For PVC piping,

select an optional code of GA, GC, or GD, use

rubber gaskets and tighten the nuts to the torque

values for the PVC piping in Table 3.3.10.

Forpermeableuids(suchasnitricacid,

hydrouoricacid,orsodiumhydrateathigh

temperatures), tighten the nuts according to the

torque values in Table 3.3.11.

CAUTION

ForaowmeterwithuorocarbonPFAlining,

it is possible that the nuts may loosen as time

passes, so tighten them regularly. Be sure to

tighten the nuts according to the prescribed

torque values. Tighten them diagonally with

the same torque values, step by step up to the

prescribed torque value.

Loading...

Loading...