<3. INSTALLATION>

3-9

IM 01E30D01-01EN

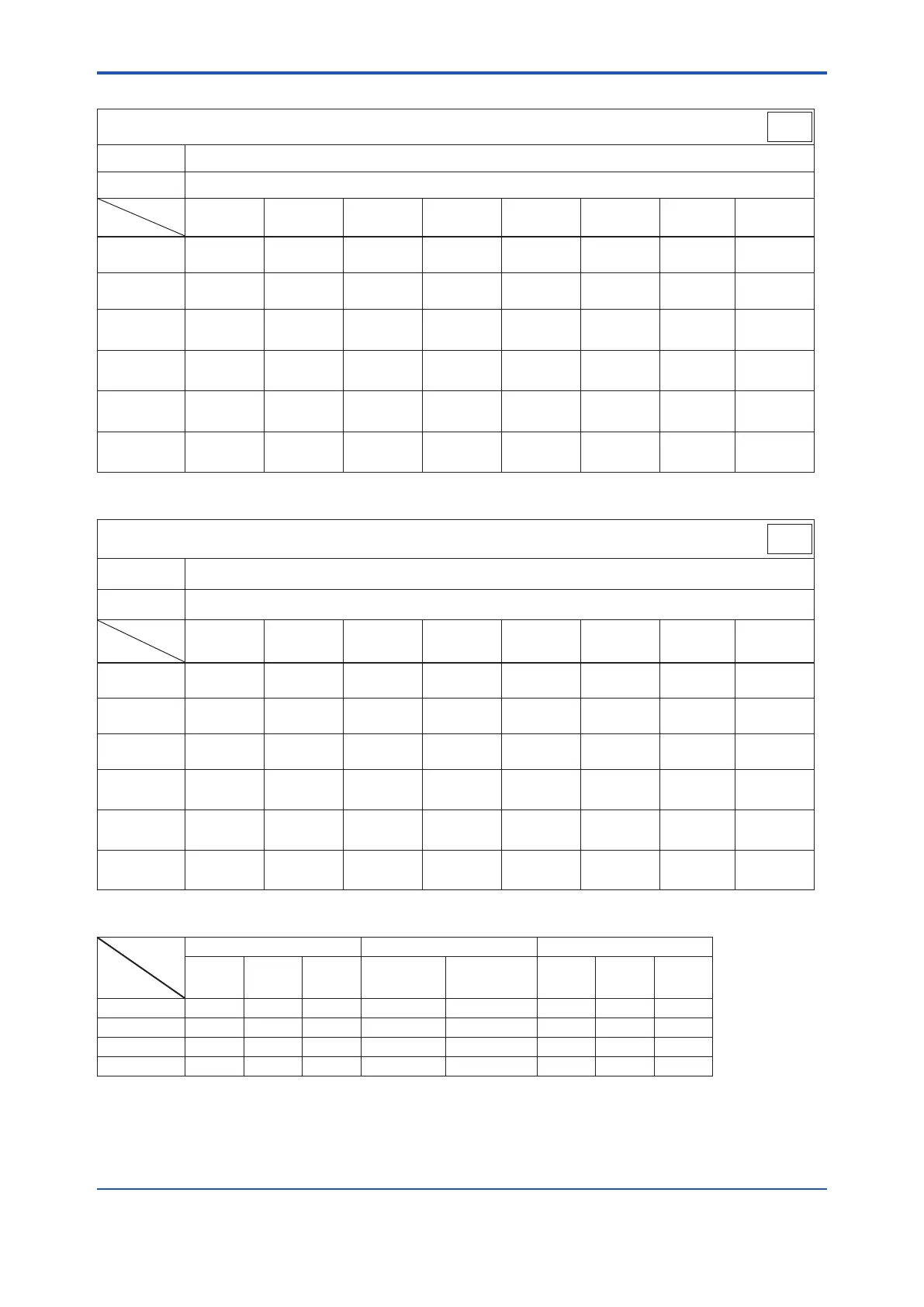

Table 3.3.5 Wafer Type Tightening Torque Values for PVC Piping

Tightening torque values for PFA lining type

Unit:

N-m

{kgf-cm}

[in-lbf]

Gasket types

withinowtube

Fluororubber gasket (optional codes GA, GC, and GD)

Gasket types

foruser’sange

Fluororubber gasket, chloroprene rubber gasket (optional code BSC), or the equivalent in hardness

Flange ratings

Size

mm (inch)

JIS 10K

ANSI Class

150

DIN PN10 JIS20K

ANSI Class

300

DIN PN16 DIN PN40

JIS F12

(JIS 75M)

50 (2.0)

9.9 to 16.5

{101.0 to 168.3}

[87.6 to 146.0]

9.9 to 16.5

{101.0 to 168.3}

[87.6 to 146.0]

—

10.6 to 17.6

{108.1 to 179.5}

[93.8 to 155.8]

10.6 to 17.6

{108.1 to 179.5}

[93.8 to 155.8]

—

9.5 to 15.9

{96.9 to 162.1}

[84.1 to 140.7]

—

65 (2.5)

14.2 to 23.7

{144.8 to 241.7}

[125.7 to 209.8]

14.2 to 23.7

{144.8 to 241.7}

[125.7 to 209.8]

—

15.5 to 25.9

{158.1 to 264.1}

[137.2 to 229.2]

15.5 to 25.9

{158.1 to 264.1}

[137.2 to 229.2]

28.2 to 51.8

{287.6 to 528.2}

[249.6 to 458.4]

— —

80 (3.0)

8.0 to 13.3

{81.6 to 135.6}

[70.8 to 117.7]

17.4 to 26.7

{177.4 to 272.3}

[154.0 to 236.3]

—

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

—

15.4 to 25.6

{157.0 to 261.0}

[136.3 to 226.6]

100 (4.0)

11.3 to 18.8

{115.2 to 191.7}

[100.0 to 166.4]

11.3 to 18.8

{115.2 to 191.7}

[100.0 to 166.4]

—

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

—

21.1 to 35.1

{215.2 to 357.9}

[186.7 to 310.6]

150 (6.0)

22.5 to 37.6

{229.4 to 383.4}

[199.1 to 332.8]

22.5 to 37.6

{229.4 to 383.4}

[199.1 to 332.8]

—

27.2 to 45.3

{277.4 to 461.9}

[240.7 to 400.9]

27.2 to 45.3

{277.4 to 461.9}

[240.7 to 400.9]

40.7 to 62.1

{415.0 to 633.2}

[360.2 to 549.6]

—

21.8 to 36.3

{222.3 to 370.2}

[192.9 to 321.3]

200 (8.0)

22.1 to 36.9

{225.4 to 376.3}

[195.6 to 326.6]

31.9 to 55.3

{325.3 to 563.9}

[282.3 to 489.4]

31.9 to 55.3

{325.3 to 563.9}

[282.3 to 489.4]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

—

23.8 to 39.6

{242.7 to 403.8}

[210.6 to 350.5]

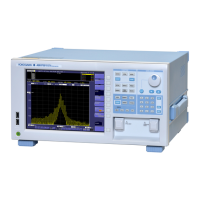

Table 3.3.6 Wafer Type Tightening Torque Values for Metal Piping and Permeable Fluids

Tightening torque values for PFA lining type

Unit:

N-m

{kgf-cm}

[in-lbf]

Gasket types

withinowtube

No gasket (standard)

Gasket types

foruser’sange

PTFE-sheathed non-asbestos gasket (optional code BSF), or the equivalent in hardness

Flange ratings

Size

mm (inch)

JIS 10K

ANSI Class

150

DIN PN10 JIS20K

ANSI Class

300

DIN PN16 DIN PN40

JIS F12

(JIS 75M)

50 (2.0)

66.2 to 76.1

{675.1 to 776.0}

[585.9 to 673.5]

66.2 to 76.1

{675.1 to 776.0}

[585.9 to 673.5]

—

33.1 to 38.0

{337.5 to 387.5}

[292.9 to 336.3]

33.1 to 38.0

{337.5 to 387.5}

[292.9 to 336.3]

—

71.2 to 118.6

{726.0 to 1209}

[630.1 to 1050]

—

65 (2.5)

89.5 to 102.9

{912.6 to 1049}

[792.1 to 910.7]

89.5 to 102.9

{912.6 to 1049}

[792.1 to 910.7]

—

44.9 to 51.6

{457.9 to 526.2}

[397.4 to 456.7]

44.9 to 51.6

{457.9 to 526.2}

[397.4 to 456.7]

81.8 to 103.2

{834.1 to 1052}

{724.0 to 913.4]

— —

80 (3.0)

51.3 to 59.0

{523.1 to 601.6}

[454.0 to 522.2]

111.3 to 118.4

{1135 to 1207}

[985.0 to 1048]

—

58.1 to 66.8

{592.5 to 681.2}

[514.2 to 591.2]

58.1 to 66.8

{592.5 to 681.2}

[514.2 to 591.2]

58.1 to 66.8

{592.5 to 681.2}

{514.2 to 591.2]

—

100.8 to 115.9

{1028 to 1182}

[892.1 to 1026]

100 (4.0)

66.7 to 76.7

{680.2 to 782.1}

[590.3 to 678.8]

66.7 to 76.7

{680.2 to 782.1}

[590.3 to 678.8]

—

76.1 to 87.5

{776.0 to 892.3}

[673.5 to 774.4]

76.1 to 87.5

{776.0 to 892.3}

[673.5 to 774.4]

76.1 to 87.5

{776.0 to 892.3}

{673.5 to 774.4]

—

129.8 to 149.3

{1324 to 1522}

[1149 to 1321]

150 (6.0)

122.0 to 140.5

{1246 to 1433}

[1082 to 1243]

122.0 to 140.5

{1246 to 1433}

[1082 to 1243]

—

86.8 to 99.8

{885.1 to 1018}

[768.2 to 883.3]

86.8 to 99.8

{885.1 to 1018}

[768.2 to 883.3]

129.8 to 136.9

{1324 to 1396}

[1149 to 1212]

—

125.6 to 144.4

{1281 to 1472}

[1112 to 1278]

200 (8.0)

111.6 to 128.3

{1138 to 1308}

[987.7 to 1136]

161.0 to 192.3

{1642 to 1961}

[1425 to 1702]

161.0 to 192.3

{1642 to 1961}

[1425 to 1702]

122.0 to 140.3

{1244 to 1431}

[1080 to 1242]

122.0 to 140.3

{1244 to 1431}

[1080 to 1242]

122.0 to 140.3

{1244 to 1431}

[1080 to 1242]

—

128.0 to 147.2

{1305 to 1501}

[1133 to 1303]

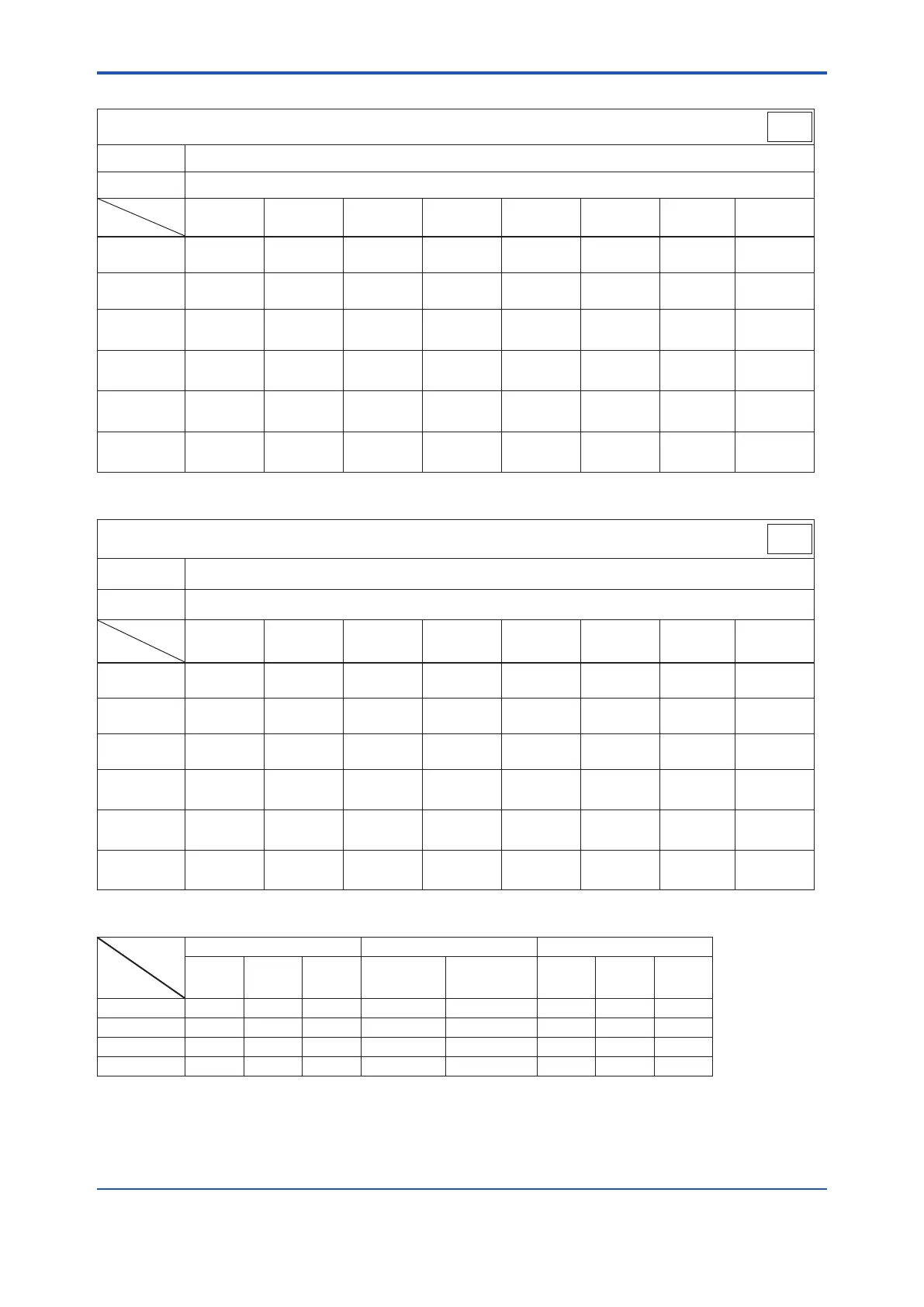

Table3.3.7 CenteringDeviceIdentication(AXRLaylengthcode1,PFAlining)

Flange

ratings

Size

mm (inch)

JIS ANSI DIN

10K 20K

F12

(75M)

150 300 PN10 PN16 PN40

80 (3.0) B F H F C — G —

100 (4.0) B F H C H — F —

150 (6.0) C D D C E — C —

200 (8.0) C D D D E C C —

*:Eachcenteringdeviceisengravedwithacharacterasidentication.

Loading...

Loading...