<3. INSTALLATION>

3-8

IM 01E30D01-01EN

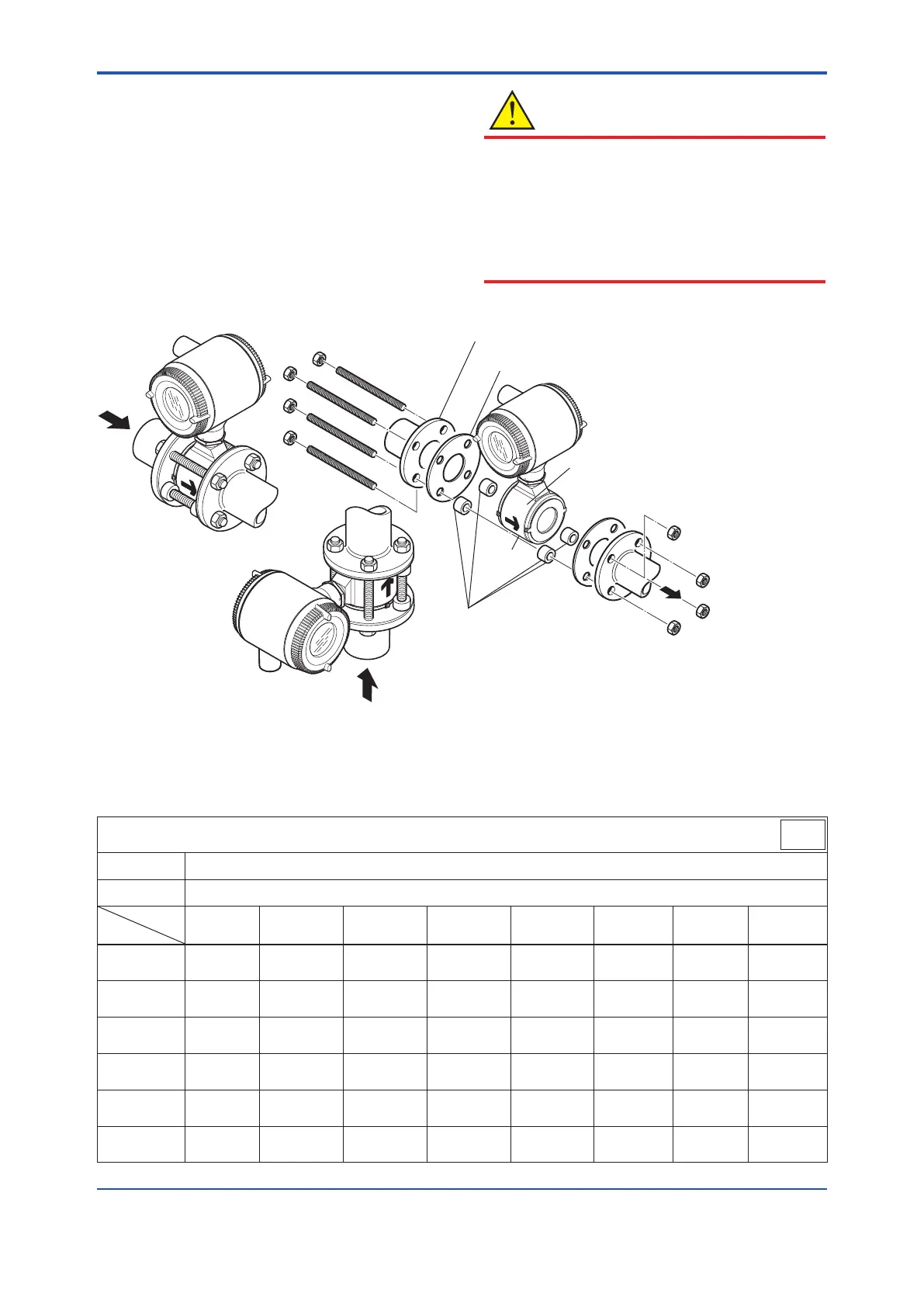

(4) Tightening Nuts

Tighten the nuts according to the torque values for

metal piping in Table 3.3.4. For PVC piping, select

an optional code of GA, GC, or GD, use rubber

gaskets and tighten the nuts to the torque values for

PVC piping in Table 3.3.5.

Forpermeableuids(suchasnitricacid,

hydrouoricacid,orsodiumhydrateathigh

temperatures), tighten the nuts according to the

torque values in Table 3.3.6.

CAUTION

ForaowmeterwithuorocarbonPFAlining,

it is possible that the nuts may loosen as time

passes, so tighten them regularly. Be sure to

tighten the nuts according to the prescribed

torque values. Tighten them diagonally with

the same torque values, step by step up to the

prescribed torque value.

Vertical mounting

Horizontal mounting

Centering device

(four units)

*Nut

*Through-bolt

*Gasket (two units)

Mini-

flange

*: These items can be ordered optionally.

If they are provided by the user, choose nuts

and bolts in compliance with the flange ratings.

Housing

Figure 3.3.2 Mounting Procedure for Wafer Type (size: 50 mm (2 in.) to 200 mm (8.0 in.))

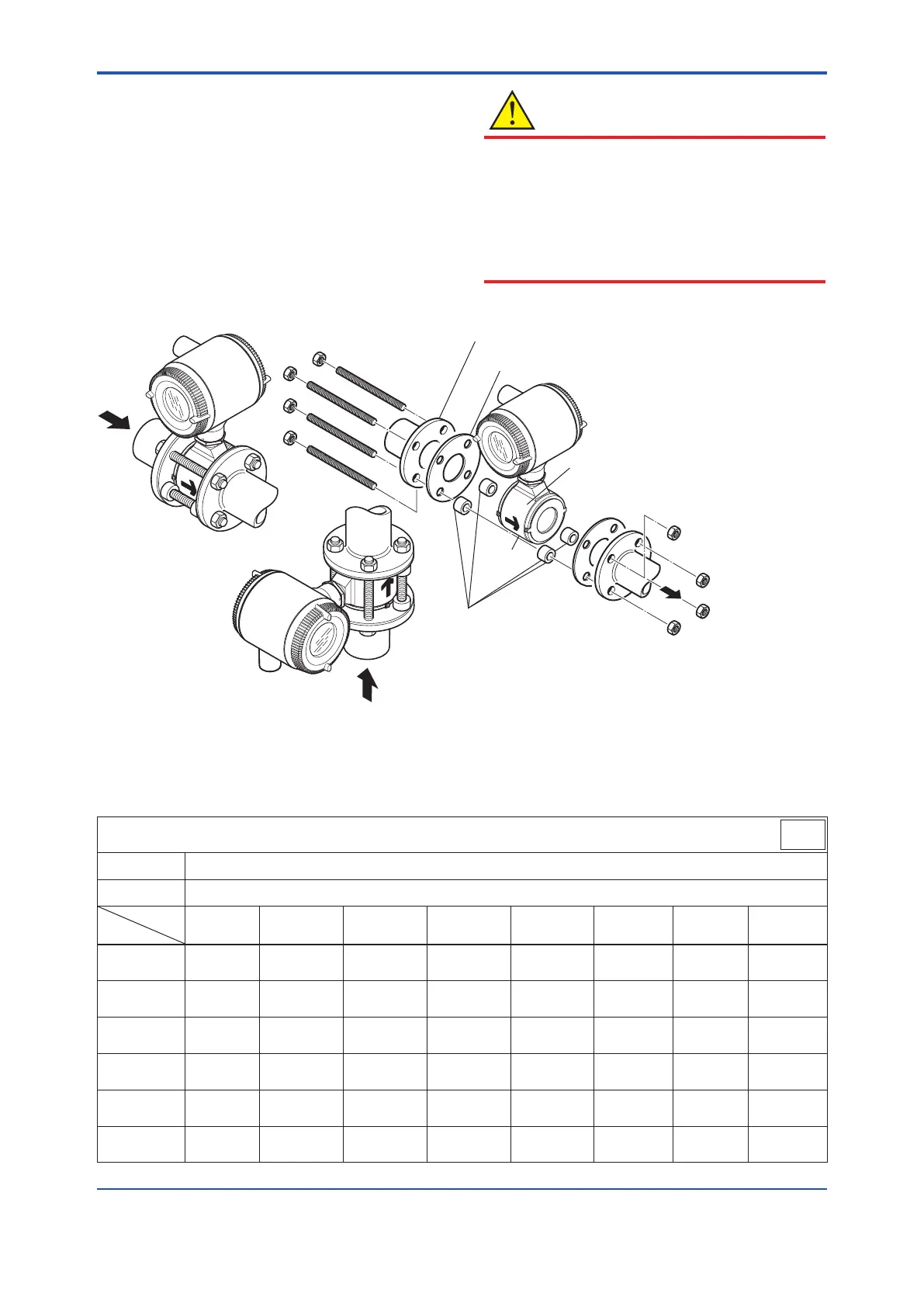

Table 3.3.4 Wafer Type Tightening Torque Values for Metal Piping

Tightening torque values for PFA lining type

Unit:

N-m

{kgf-cm}

[in-lbf]

Gasket types

withinowtube

No gasket (standard)

Gasket types

foruser’sange

Non-asbestosbergasket,PTFE-sheathednon-asbestosgasket

(optional code BSF), or the equivalent in hardness

Flange ratings

Size

mm (inch)

JIS 10K ANSI Class 150 DIN PN10 JIS20K ANSI Class 300 DIN PN16 DIN PN40

JIS F12

(JIS 75M)

50 (2.0)

45.0 to 56.8

{4 58.9 to 579.2}

[398.3 to 502.7

]

45.0 to 56.8

{458.9 to 579.2}

[398.3 to 502.7]

—

22.5 to 25.9

{229.4 to 264.1}

[199.1 to 229.2]

22.5 to 25.9

{229.4 to 264.1}

[199.1 to 229.2]

—

50.0 to 57.5

{509.9 to 586.3}

[442.5 to 508.9}

—

65 (2.5)

61.3 to 70.5

{625.1 to 718.9}

[542.5 to 624.0]

61.3 to 70.5

{625.1 to 718.9}

[542.5 to 624.0]

—

30.8 to 35.4

{314.1 to 361.0}

[272.6 to 313.3]

30.8 to 35.4

{314.1 to 361.0}

[272.6 to 313.3]

56.1 to 70.8

{572.1 to 722.0}

[496.5 to 626.6]

— —

80 (3.0)

35.0 to 40.3

{356.9 to 410.9}

[309.8 to 356.7]

76.0 to 80.9

{775.0 to 825.0}

[672.6 to 716.0]

—

39.9 to 45.9

{406.9 to 468.1}

[353.1 to 406.2]

39.9 to 45.9

{406.9 to 468.1}

[353.1 to 406.2]

39.9 to 45.9

{406.9 to 468.1}

[353.1 to 406.2]

—

68.4 to 78.7

{697.5 to 802.5}

[605.4 to 696.5]

100 (4.0)

46.1 to 53

{470.1 to 540.5}

[408.0 to 469.1]

46.1 to 53

{470.1 to 540.5}

[408.0 to 469.1]

—

52.9 to 60.8

{539.4 to 620.0}

[468.2 to 538.1]

52.9 to 60.8

{539.4 to 620.0}

[468.2 to 538.1]

52.9 to 60.8

{539.4 to 620.0}

[468.2 to 538.1]

—

88.6 to 101.9

{903.5 to 1039}

[784.1 to 901.9]

150 (6.0)

85.4 to 98.2

{870.8 to 1001}

[755.8 to 869.1]

85.4 to 98.2

{870.8 to 1001}

[755.8 to 869.1]

—

61.0 to 70.2

{622.0 to 715.8}

[539.9 to 621.3]

61.0 to 70.2

{622.0 to 715.8}

[539.9 to 621.3]

91.2 to 96.3

{930.0 to 982.0}

[807.2 to 852.3]

—

86.3 to 99.2

{880.0 to 1012}

[763.8 to 878.0]

200 (8.0)

78.8 to 90.6

{803.5 to 923.9}

[697.4 to 801.8]

113.6 to 135.8

{1158 to 1385}

[1005 to 1202]

113.6 to 135.8

{1158 to 1385}

[1005 to 1202]

87.5 to 100.6

{892.3 to 1026}

[774.4 to 890.3]

87.5 to 100.6

{892.3 to 1026}

[774.4 to 890.3]

87.5 to 100.6

{892.3 to 1026}

[774.4 to 890.3]

—

88.6 to 101.9

{903.5 to 1039}

[784.1 to 901.9]

Loading...

Loading...