<3. INSTALLATION>

3-7

IM 01E30D01-01EN

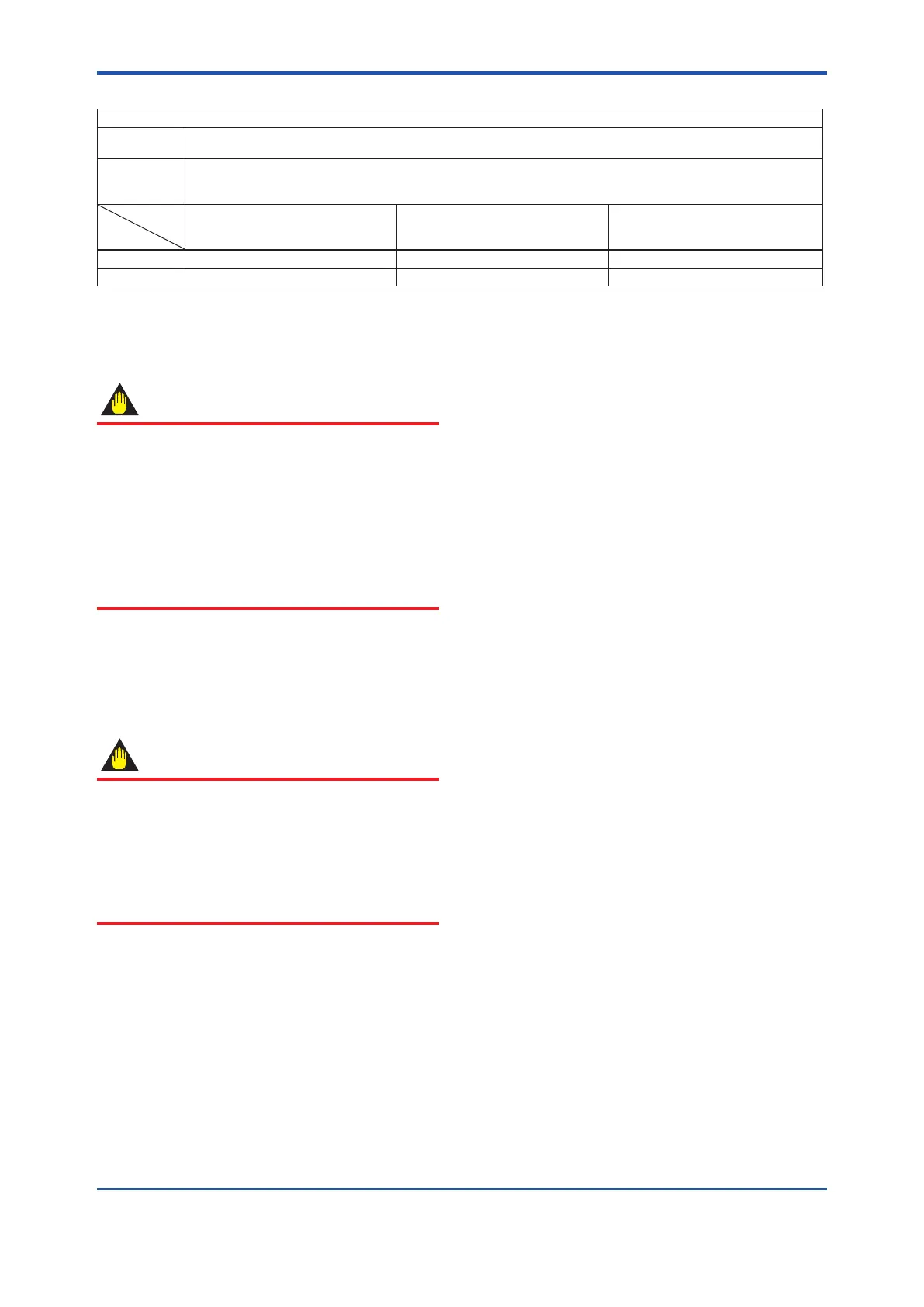

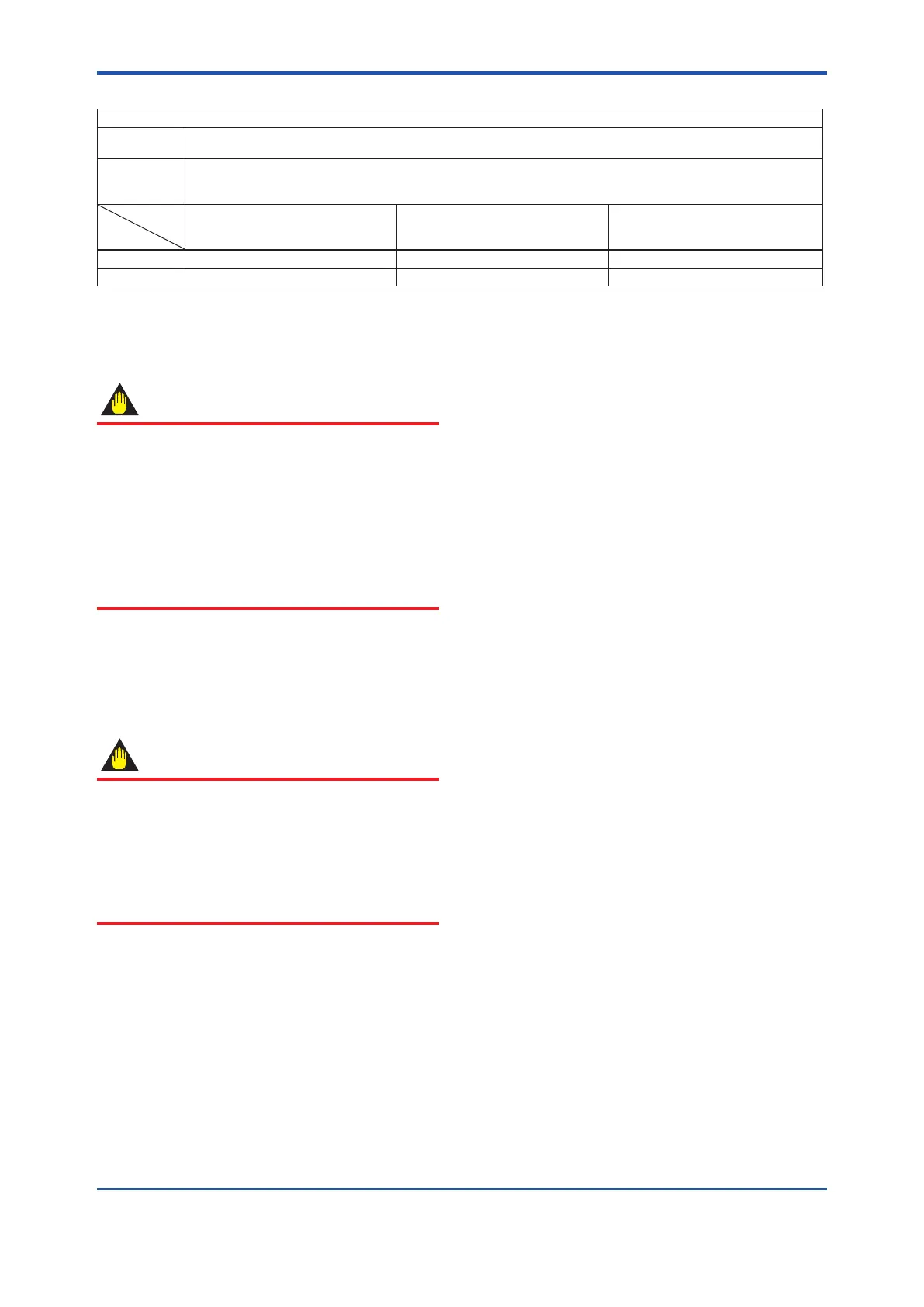

Table 3.3.3 Wafer Type Tightening Torque Values for Metal Piping and Permeable Fluids

TighteningtorquevaluesforPFAliningtype(N-m/{kgf-cm}/[in-lbf])

Gasket types

withinowtube

No gasket (standard)

Gasket types

for user’s

ange

PTFE-sheathed non-asbestos gasket (optional code BSF), or the equivalent in hardness

Flange ratings

Size

mm (inch)

JIS 10K, ANSI Class 150, and DIN PN10 JIS 20K, ANSI Class 300, and DIN PN16 DIN PN40

25 (1.0) 34.9 to 40.1 / {355.9 to 408.9} / [308.9 to 354.9] 35.2 to 40.1 / {358.9 to 408.9} / [311.5 to 354.9] 32.3 to 37.1 / {329.4 to 378.3} / [285.9 to 328.4]

40 (1.5) 53.5 to 61.5 / {545.5 to 627.1} / [473.5 to 544.3] 54.2 to 61.5 / {552.7 to 627.1} / [479.7 to 544.3] 56.4 to 61.5 / {575.1 to 627.1} / [499.2 to 544.3]

3.3.2 Nominal Diameter 50 mm (2.0 in.) to

200 mm (8.0 in.), Wafer Type

IMPORTANT

Useboltsandnutsincompliancewiththeange

ratings. When stud-type through-bolts are used,

be sure the outside diameter of the shank is

smaller than that of the thread ridge. Be sure to

choose a gasket with inner and outer diameters

that does not protrude inside the piping (Read

Subsection 3.3.4). If the inner diameter of the

gasket is too large, or outer diameter of the

gasketistoosmall,uidleakagemayresult.

(1) Mounting Direction

Mounttheowmetersothattheowdirectionofthe

uidtobemeasuredisinlinewiththedirectionof

thearrowmarkontheowmeter.

IMPORTANT

If it is impossible to match the direction of

the arrow mark, the direction of the electrical

connection can be changed. Read Section 11.1

to do this properly.

Incasetheuidbeingmeasuredowsagainst

the arrow direction, read this parameter J20:

Flow Direction in this user’s manual.

(2) Mounting Centering Devices

Tomaintainconcentricityoftheowmeterwiththe

pipes, install centering devices. From the process

piping side, pass two through-bolts through the

four centering devices (two for each bolt) and

the adjacent two holes (the lower two holes for

horizontalmounting)ofbothoftheanges(Read

Figure 3.3.2). Use the appropriate centering

devices according to the nominal diameter and the

angeratings.Thecenteringdevicesareengraved

with an identifying character. Use the appropriate

oneswhichmeettherequiredspecicationsby

reading Table 3.3.7 and Table 3.3.8.

(3) Positioning the Flowmeter

PositiontheowmetersothattheMini-angesand

the centering devices come in close contact with

each other. Be careful to prevent the four centering

devices from coming into contact with the housing.

If stud-type through-bolts are used, position them

in such a way that the four centering devices come

in contact with the bolt threads (Read Figure 3.3.2).

Pass the other through-bolts through from the

process piping side.

Loading...

Loading...