<3. INSTALLATION>

3-11

IM 01E30D01-01EN

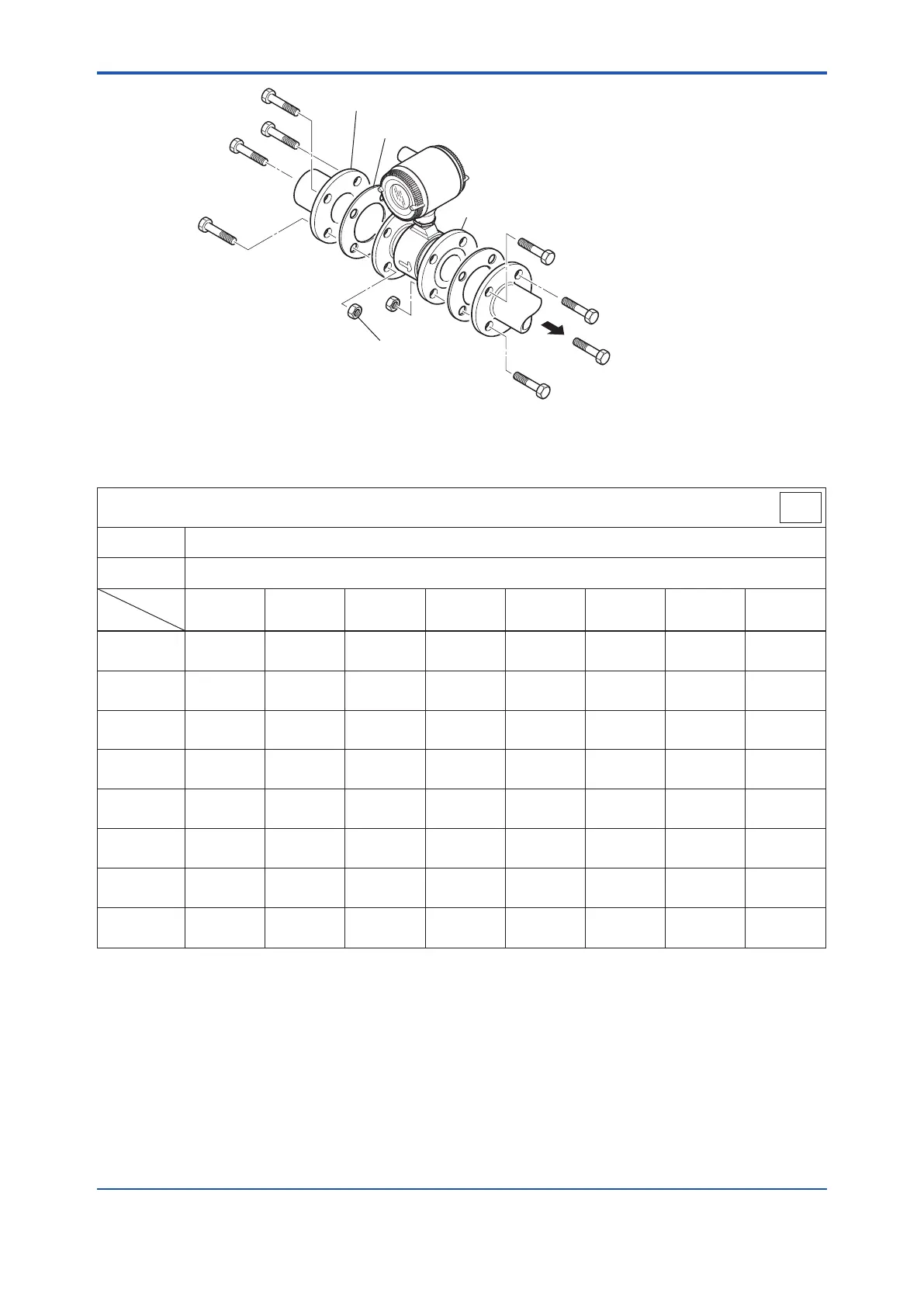

*Gasket (two units)

*Piping-side flange

*Bolt

Flowmeter-side flange

*: These items must be provided by the user.

Choose nuts and bolts in compliance with

the flange ratings.

*Nut

Figure 3.3.3 Mounting Procedure for Flange Type (size: 25 mm (1.0 in.) to 200 mm (8.0 in.))

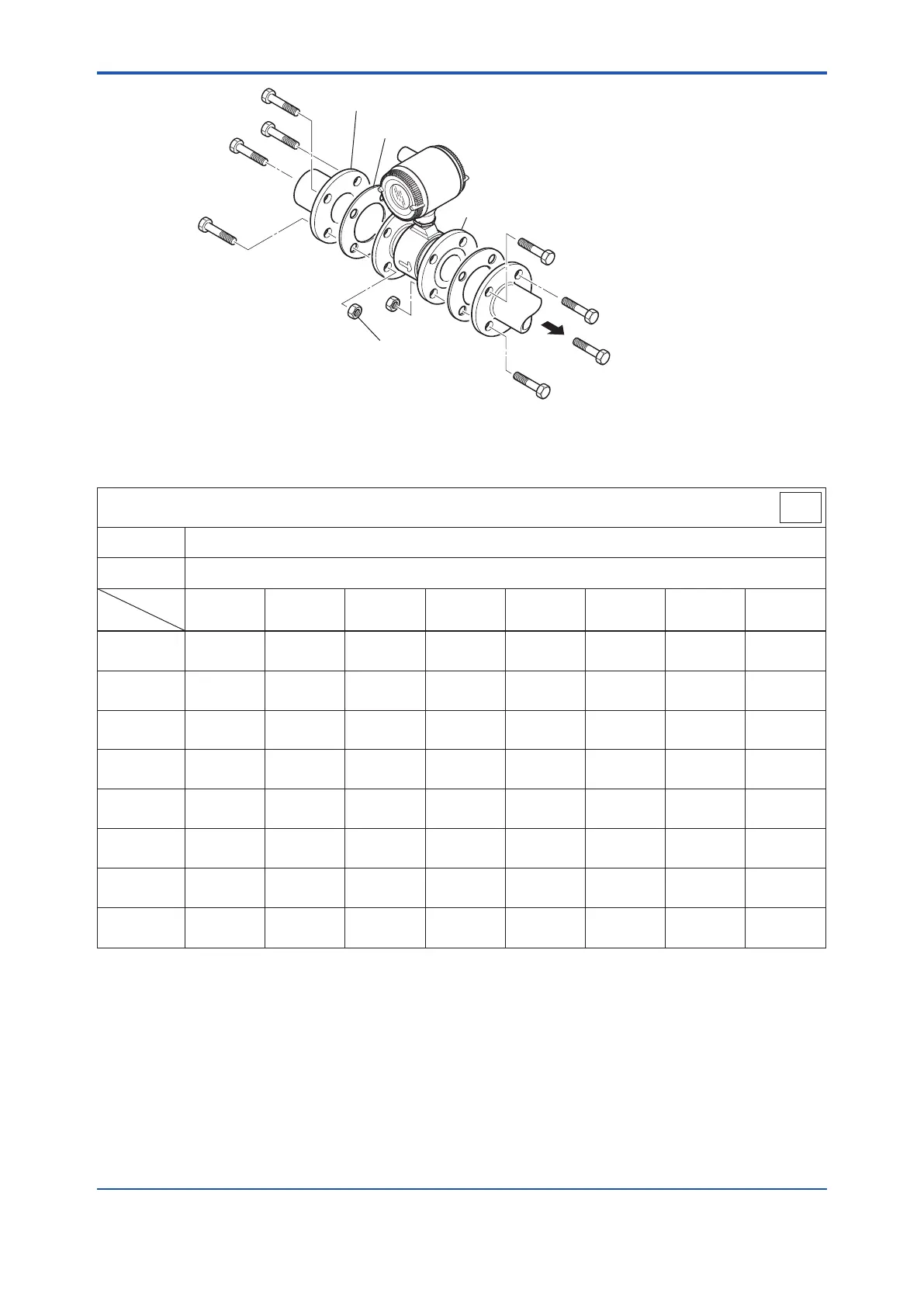

Table 3.3.9 Flange Type Tightening Torque Values for Metal Piping

Tightening torque values for PFA lining type

Unit:

N-m

{kgf-cm}

[in-lbf]

Gasket types

withinowtube

No gasket (standard)

Gasket types

foruser’sange

Non-asbestos gasket, PTFE-sheathed non-asbestos gasket, or the equivalent in hardness

Flange ratings

Size

mm (inch)

JIS 10K

ANSI Class

150

DIN PN10 JIS20K

ANSI Class

300

DIN PN16 DIN PN40

JIS F12

(JIS 75M)

25 (1.0)

13.1 to 15.1

{133.6 to 154.0}

[115.9 to 133.6]

13.1 to 15.1

{133.6 to 154.0}

[115.9 to 133.6]

—

13.2 to 15.2

{134.6 to 155.0}

[116.8 to 134.5]

13.2 to 15.2

{134.6 to 155.0}

[116.8 to 134.5]

—

11.9 to 13.7

{121.3 to 139.7}

[105.3 to 121.3]

—

40 (1.5)

21.9 to 25.2

{223.3 to 257.0}

[193.8 to 223.0]

21.9 to 25.2

{223.3 to 257.0}

[193.8 to 223.0]

—

22.2 to 25.5

{226.4 to 260.0}

[196.5 to 225.7]

22.2 to 25.5

{226.4 to 260.0}

[196.5 to 225.7]

—

15.0 to 17.3

{153.0 to 176.4}

[132.8 to 153.1]

—

50 (2.0)

28.0 to 32.2

{285.5 to 328.3}

[247.8 to 285.0]

28.0 to 32.2

{285.5 to 328.3}

[247.8 to 285.0]

—

27.8 to 32.0

{283.5 to 326.3}

[246.0 to 283.2]

27.8 to 32.0

{283.5 to 326.3}

[246.0 to 283.2]

—

23.2 to 26.7

{236.6 to 272.3}

[205.3 to 236.3]

—

65 (2.5)

41.6 to 47.8

{424.2 to 487.4}

[368.2 to 423.0]

41.6 to 47.8

{424.2 to 487.4}

[368.2 to 423.0]

—

19.5 to 28.5

{198.8 to 290.6}

[172.6 to 252.2]

19.5 to 28.5

{198.8 to 290.6}

[172.6 to 252.2]

41.4 to 47.6

{422.2 to 485.4}

[366.4 to 421.3]

28.8 to 33.1

{293.7 to 337.5}

[254.9 to 293.0]

—

80 (3.0)

23.2 to 26.7

{236.6 to 272.3}

[205.3 to 236.3]

52.7 to 53.6

{536.9 to 546.2}

[466.0 to 474.1]

—

26.1 to 30.0

{266.1 to 305.9}

[231.0 to 265.5]

26.1 to 30.0

{266.1 to 305.9}

[231.0 to 265.5]

26.1 to 30.0

{266.1 to 305.9}

[231.0 to 265.5]

—

46.0 to 52.9

{469.1 to 539.4}

[407.1 to 468.2

100 (4.0)

30.9 to 35.5

{315.1 to 362.0}

[273.5 to 314.2]

30.9 to 35.5

{315.1 to 362.0}

[273.5 to 314.2]

—

34.8 to 40.0

{354.9 to 407.9}

[308.0 to 354.0]

34.8 to 40.0

{354.9 to 407.9}

[308.0 to 354.0]

34.8 to 40.0

{354.9 to 407.9}

[308.0 to 354.0]

—

60.9 to 70.0

{621.0 to 713.8}

[539.0 to 619.5]

150 (6.0)

64.5 to 74.2

{657.7 to 756.6}

[570.8 to 656.7]

64.5 to 74.2

{657.7 to 756.6}

[570.8 to 656.7]

—

44.8 to 51.5

{456.8 to 525.2}

[396.5 to 455.8]

44.8 to 51.5

{456.8 to 525.2}

[396.5 to 455.8]

66.7 to 80.8

{680.2 to 823.9}

[590.3 to 715.1]

—

67.5 to 77.6

{688.3 to 791.3}

[597.4 to 686.8]

200 (8.0)

59.2 to 68.1

{603.7 to 694.4}

[523.9 to 602.7]

100.3 to 102.1

{1023 to 1041}

[887.8 to 903.3]

100.3 to 102.1

{1023 to 1041}

[887.8 to 903.3]

63.6 to 73.1

{648.5 to 745.4}

[562.9 to 647.0]

63.6 to 73.1

{648.5 to 745.4}

[562.9 to 647.0]

63.6 to 73.1

{648.5 to 745.4}

[562.9 to 647.0]

—

69.9 to 80.4

{712.8 to 819.9}

[618.6 to 711.6]

Loading...

Loading...