Recommended annual actions by the user

Inspections by user

IIP22 and IP42 air inlet and outlet meshes

ITightness of terminals

IDustiness, corrosion and temperature

IHeatsink cleaning

Other

IABB-SACE Air circuit breaker maintenance

IABB Contactors maintenance

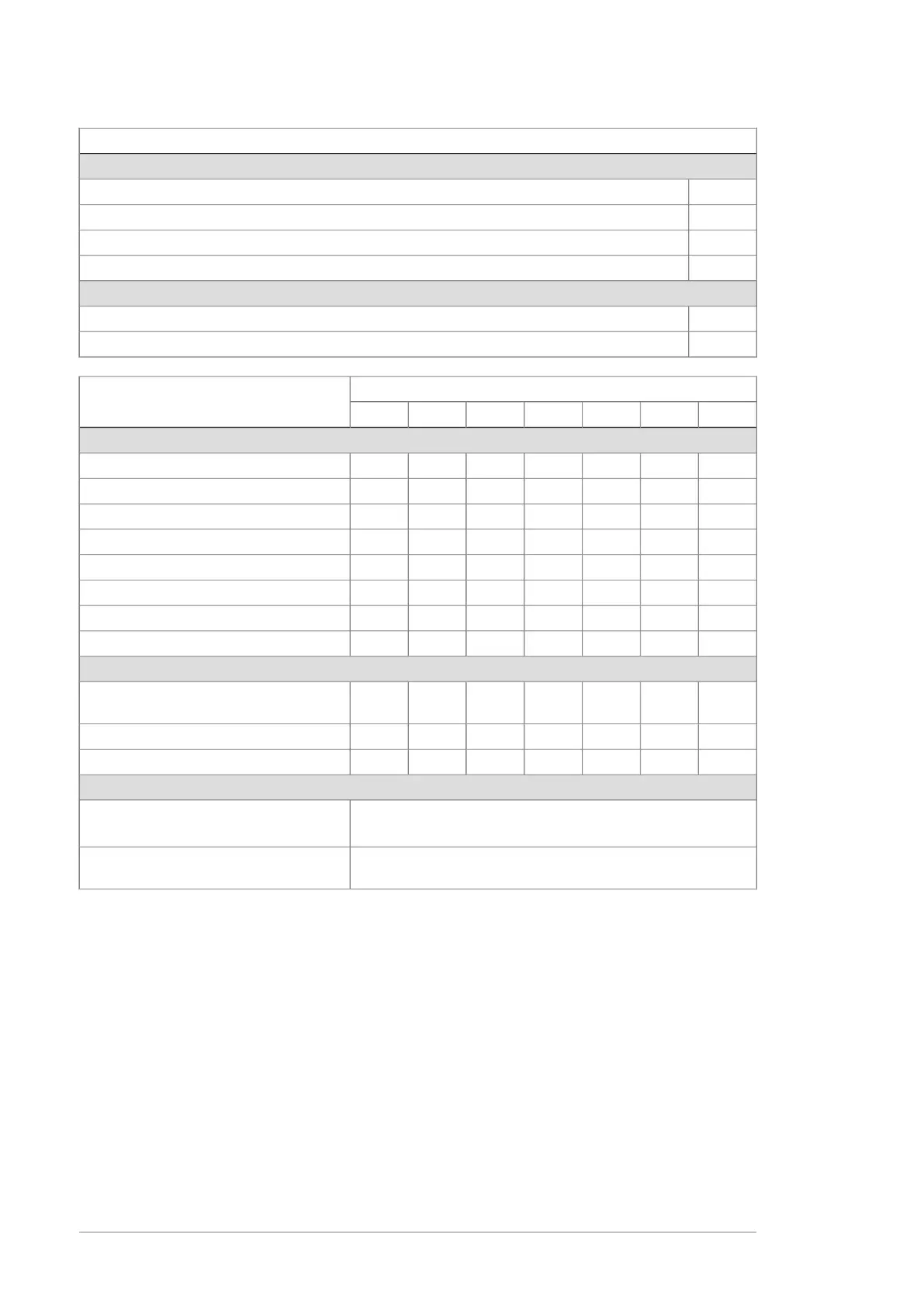

Years from start-upItem

21181512963

Cooling

RRInverter module main cooling fan

RRFrame R5i auxiliary cooling fan

RRCircuit board cooling fan

RRCabinet cooling fan, internal (50 Hz)

RRRCabinet cooling fan, internal (60 Hz)

RRCabinet cooling fan, door (50 Hz)

RRCabinet cooling fan, door (60 Hz)

RRNSIN filter cooling fan

Aging

RRRZCU/BCU control unit battery (Real-time

clock)

RRControl panel battery (Real-time clock)

RCabinet auxiliary power supplies

Functional safety

ISafety function test

Refer to the maintenance information of the safety function.

20 yearsSafety component expiry (Mission time

T

M

)

Note:

• Maintenance and component replacement intervals are based on the assumption

that the equipment is operated within the specified ratings and ambient

conditions. ABB recommends annual drive inspections to ensure the highest

reliability and optimum performance.

• Long term operation near the specified maximum ratings or ambient conditions

may require shorter maintenance intervals for certain components. Consult your

local ABB Service representative for additional maintenance recommendations.

Maintenance timers and counters

The control program has maintenance timers and counters that can be configured to

generate a warning when a pre-defined limit is reached. Each timer/counter can be

104 Maintenance

Loading...

Loading...