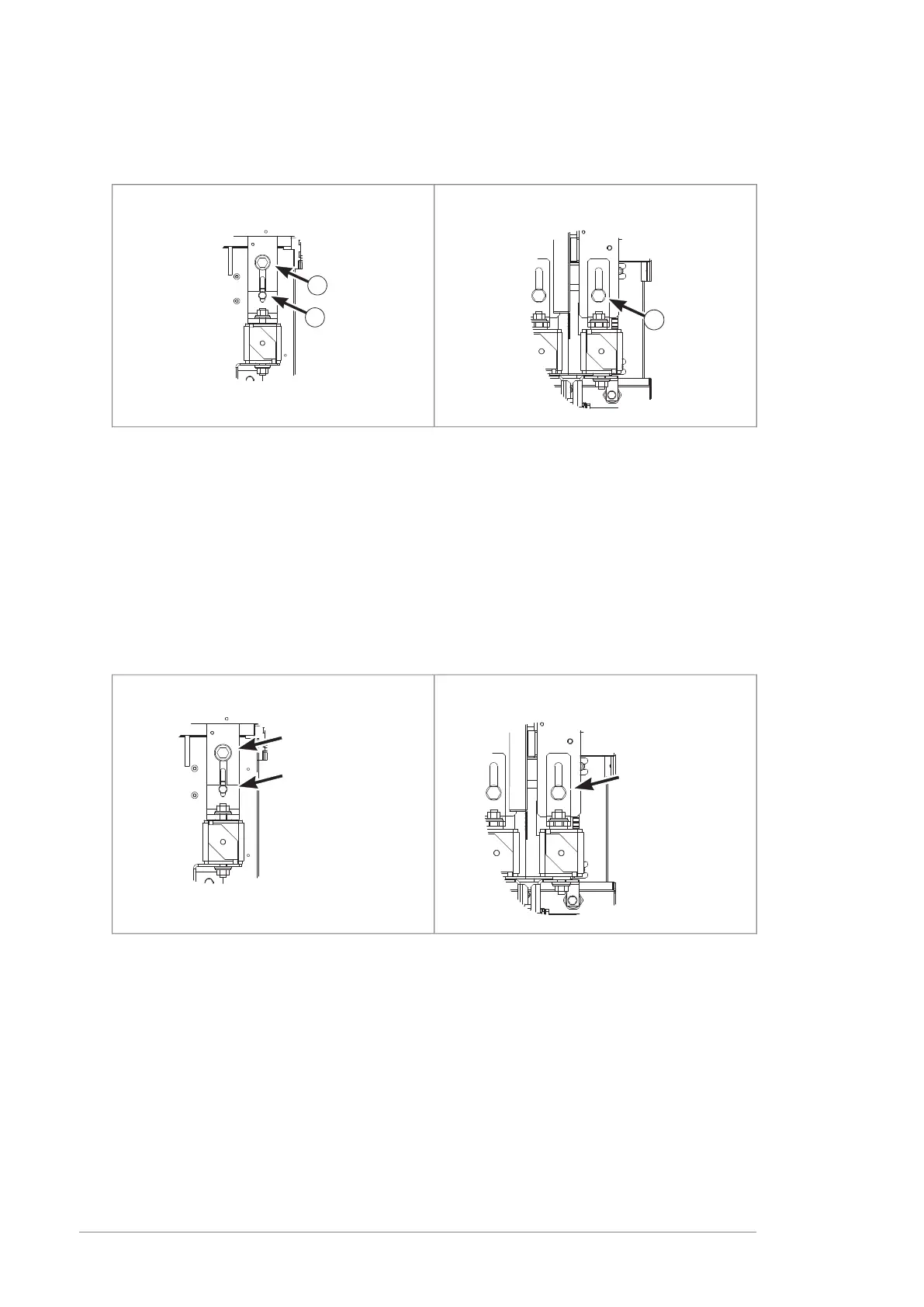

4. Loosen the mounting screws of the top busbar (c) so that you can adjust the gap

for the fuse block.

With DC switch (+F286)

Without DC switch

5. Slide out the fuse block.

6. Move the screws, nuts and washers from the blown fuse to the new fuse. Make

sure to keep the washers in the original order.

Note: See the technical data for a table of recommended fuses.

7. Insert the new fuse block into its slot. Tighten both nuts of the fuse only until

there is no play between the fuse and the busbars.

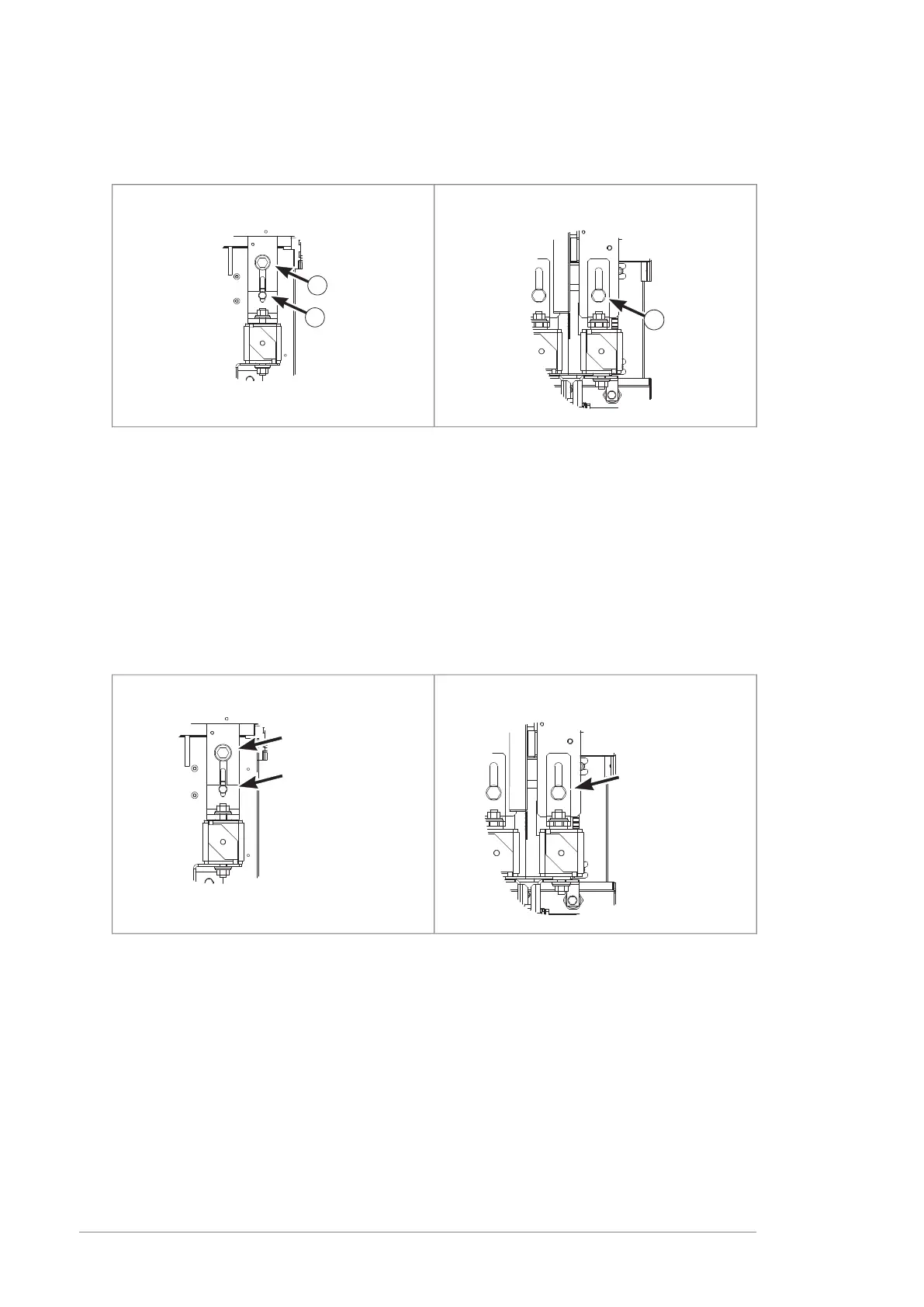

8. Tighten the mounting screws of the top busbars to the tightening torque shown

in the figures below.

With DC switch (+F286)

Without DC switch

70 N·m (52 lbf·ft)

9 N·m (6.6 lbf·ft)

9. Tighten the fuse block nuts to the correct tightening torque:

• Cooper-Bussmann fuses: 50 N·m (37 lbf·ft)

• Mersen (Ferraz Shawmut) fuses: 46 N·m (34 lbf·ft)

• Other: Refer to the fuse manufacturer’s instructions.

10. Install the shroud removed earlier. Tighten the screws to 6 N·m (4.4 lbf·ft).

Capacitors

The intermediate DC circuit of the drive contains several electrolytic capacitors.

Operating time, load, and surrounding air temperature have an effect on the life of

the capacitors. Capacitor life can be extended by decreasing the surrounding air

temperature.

136 Maintenance

Loading...

Loading...