Transporting the Robot

Adept Viper s650/s850 Robot with MB-60R User’s Guide, Rev D 25

Mounting the Robot

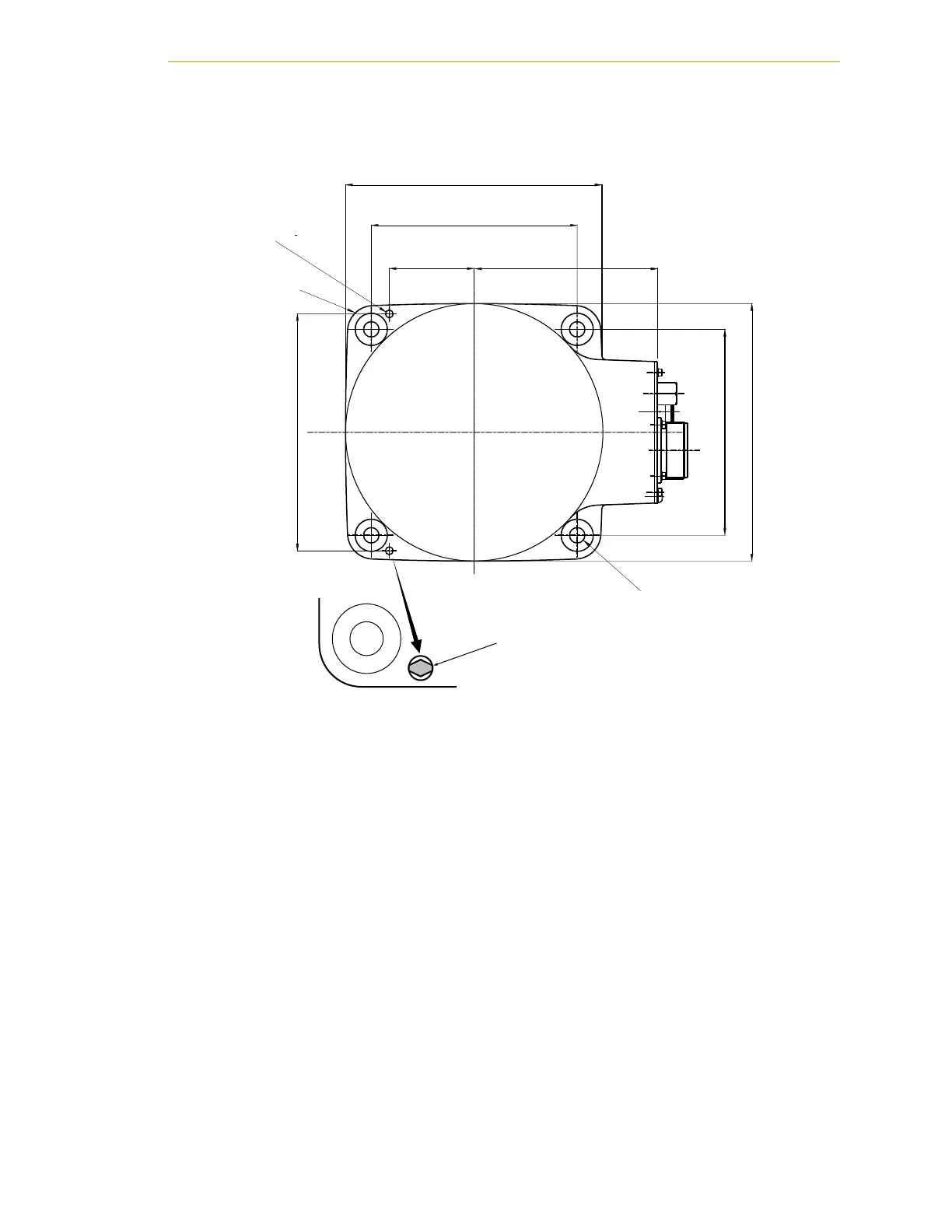

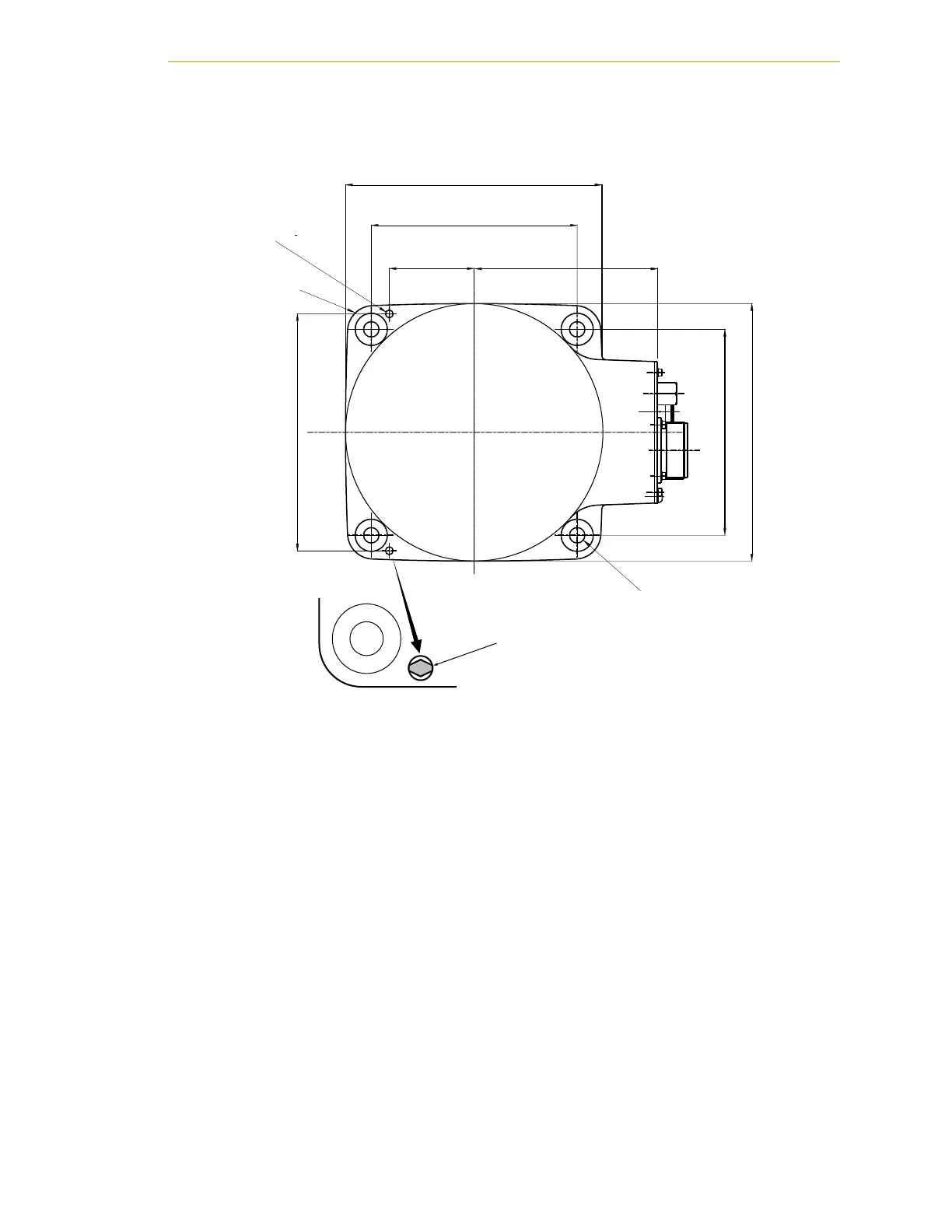

Figure 2-5. Mounting Hole Pattern for Robot

1. See the preceding figure for the dimensions of the mounting holes in the robot

mounting position where the robot is to be secured.

• Drill four bolt holes (M10), 20 mm deep or more.

• Drill a dowel pin hole Ø6, H7 for the diamond shaped pin, 10 mm deep or

more.

• Drill a dowel pin hole Ø6, H7 for the internally threaded positioning pin,

10 mm deep or more.

2. Locate two alignment pins, one round and one diamond-shaped, supplied in the

accessory kit.

3. Drive the diamond-shaped pin into one Ø6, H7 hole so that it is oriented as

shown in Figure 2-5.

4. Drive the internally threaded alignment pin into the other Ø6, H7 hole.

NOTE: Be sure to use the alignment pins. It can minimize positional

deviations that may be caused by the removal/installation of the robot

for maintenance and reduce vibration during operation.

1

R2

.

142.

12 THR

For M1

4

.

160

200

+

.

12

iamond-sha

ed

in

Loading...

Loading...