i2000SR interface module Service Manual

Page 96 of 212 625798100.APS.5.doc

STEPS REFERENCES

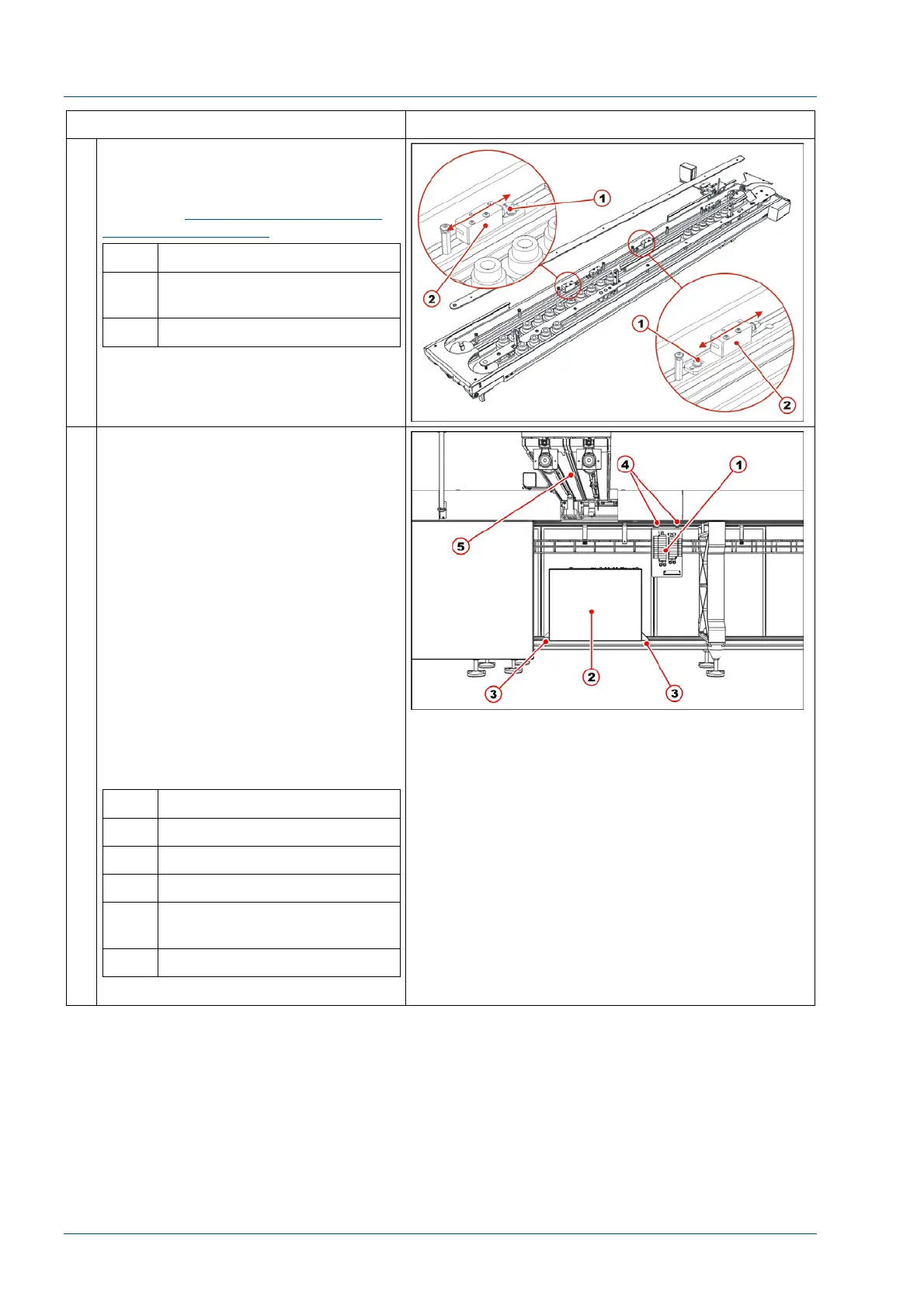

27 Verify that the two carriers at the

stop gate are under the vertical of

the i2000SR sample points.

If not, see

Alignment of routine and

STAT sampling gates

procedure.

No. Description

1 Screw to loosen for stop

gate fine positioning

2 Sample points stop gate

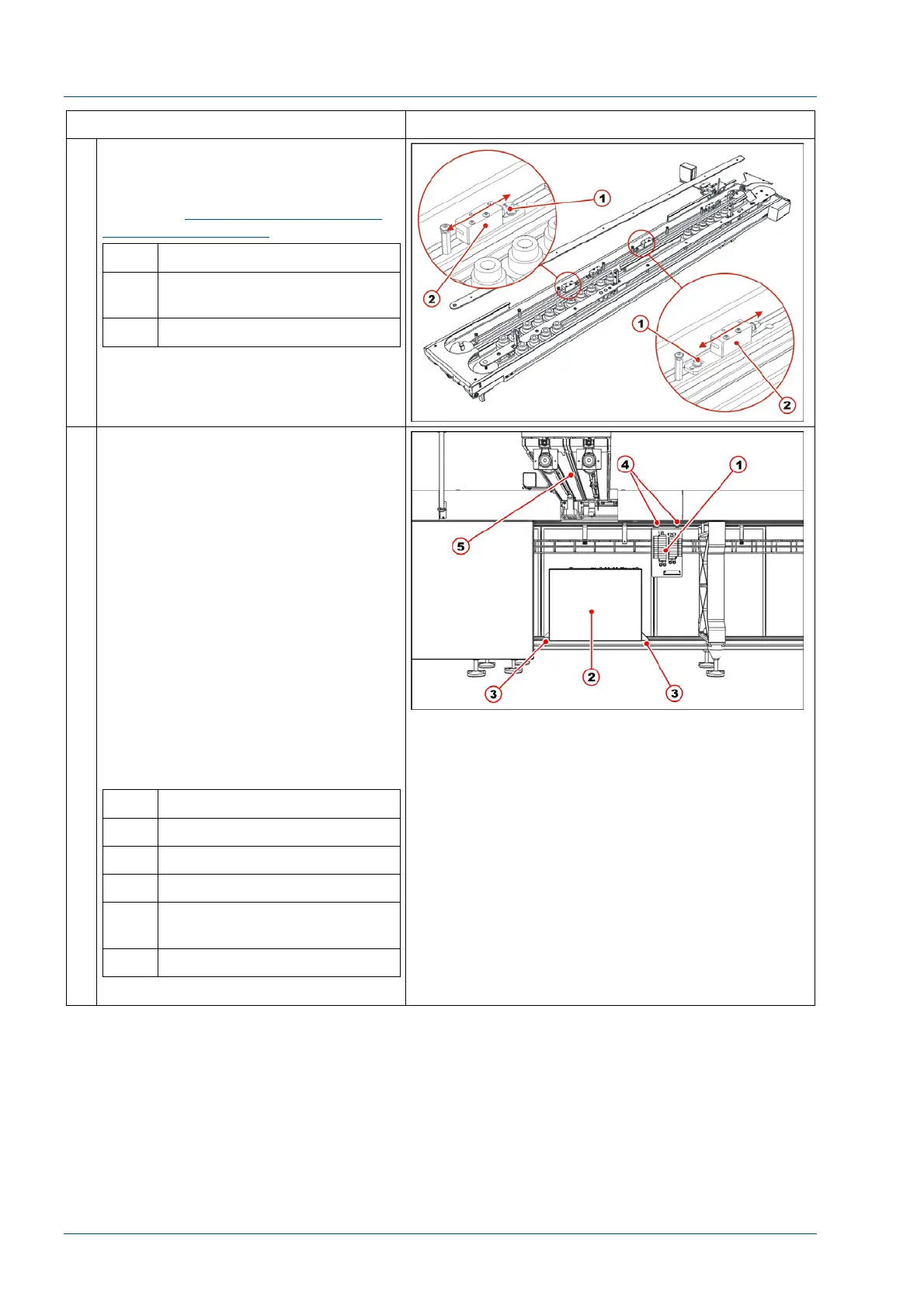

28 Install Pneumatic panel on the TMA.

The manufacturer has not defined the

exact position as to where to fasten

the Pneumatic panel on the TMA. The

FSE will have to look for a convenient

fixing point avoiding TMA feet

encumbrance.

Do not install the pneumatic panel at

the left of the IM or it will be

unreachable for maintenance

operations because it will be covered

by the i2000SR.

Refer to the pneumatic working

drawing to re-establish pneumatic

connections. Each pneumatic tube is

identified with two labels, one on

each tube extreme and has to be

connected to the corresponding

labeled devices.

No. Description

1 Pneumatic panel

2 Electrical box

3 Electrical box fasten points

4 Pneumatic panel fasten

bolts

5 i2000SR IM body

Loading...

Loading...