2-20 2007 Buell P3: Chassis

HOME

REMOVAL

1. Remove wheel from motorcycle. See 2.5 FRONT

WHEEL or 2.6 REAR WHEEL.

2. Rear wheel only: Remove rear sprocket. See 2.6 REAR

WHEEL (Disassembly).

3. Deflate tire. Use a valve core tool to remove valve core

from valve stem.

11WARNING1WARNING

Read the operating manual for the manufacturer and

model of tire machine used. Failure to follow operational

procedures or to heed any cautions/warnings in the man-

ual for the tire machine could result in death or serious

injury. (00283a)

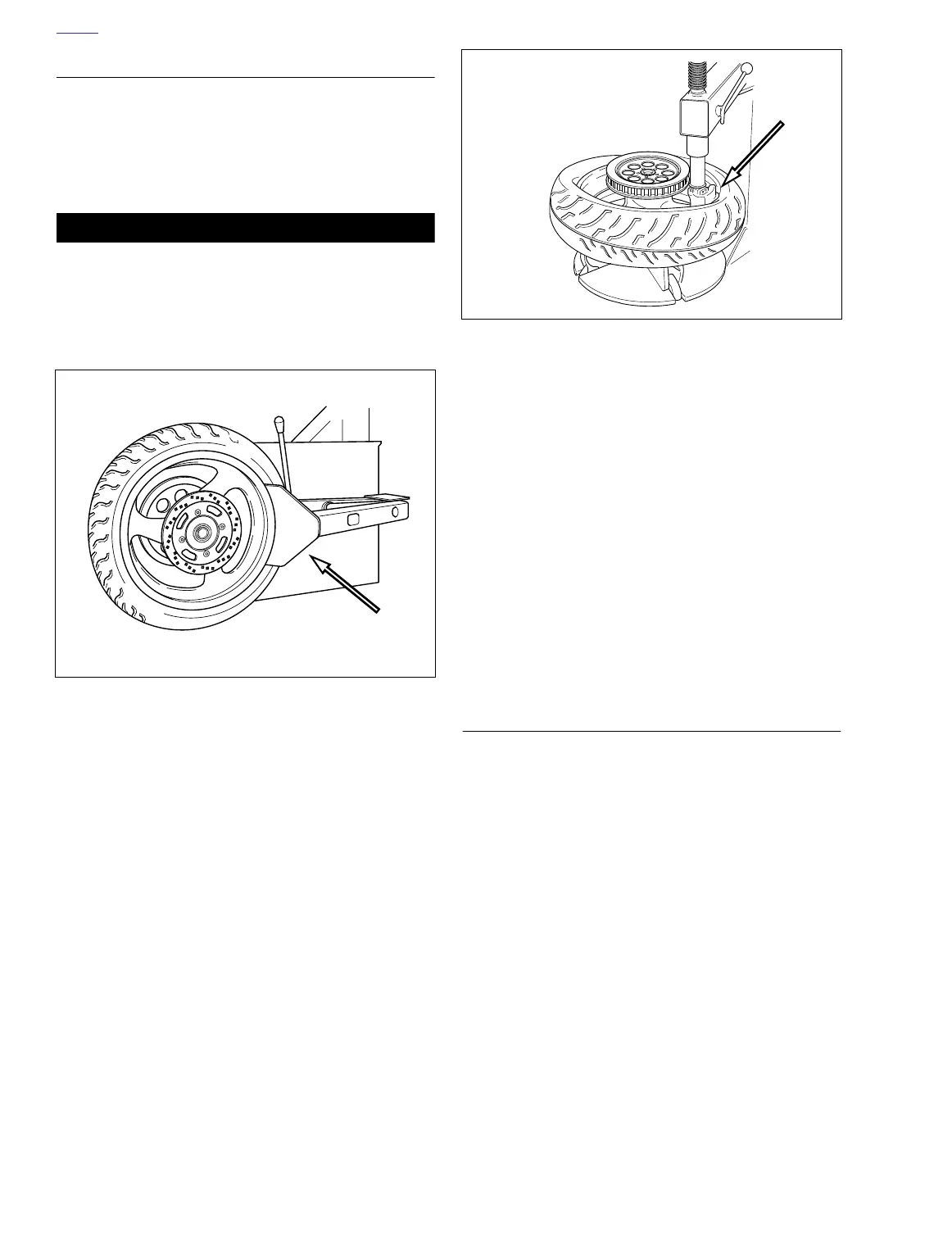

4. See Figure 2-20. Use a pneumatic bead breaker to

loosen bead. Rotate wheel and apply bead breaker at

several points along circumference of the rim until entire

bead drops into rim well.

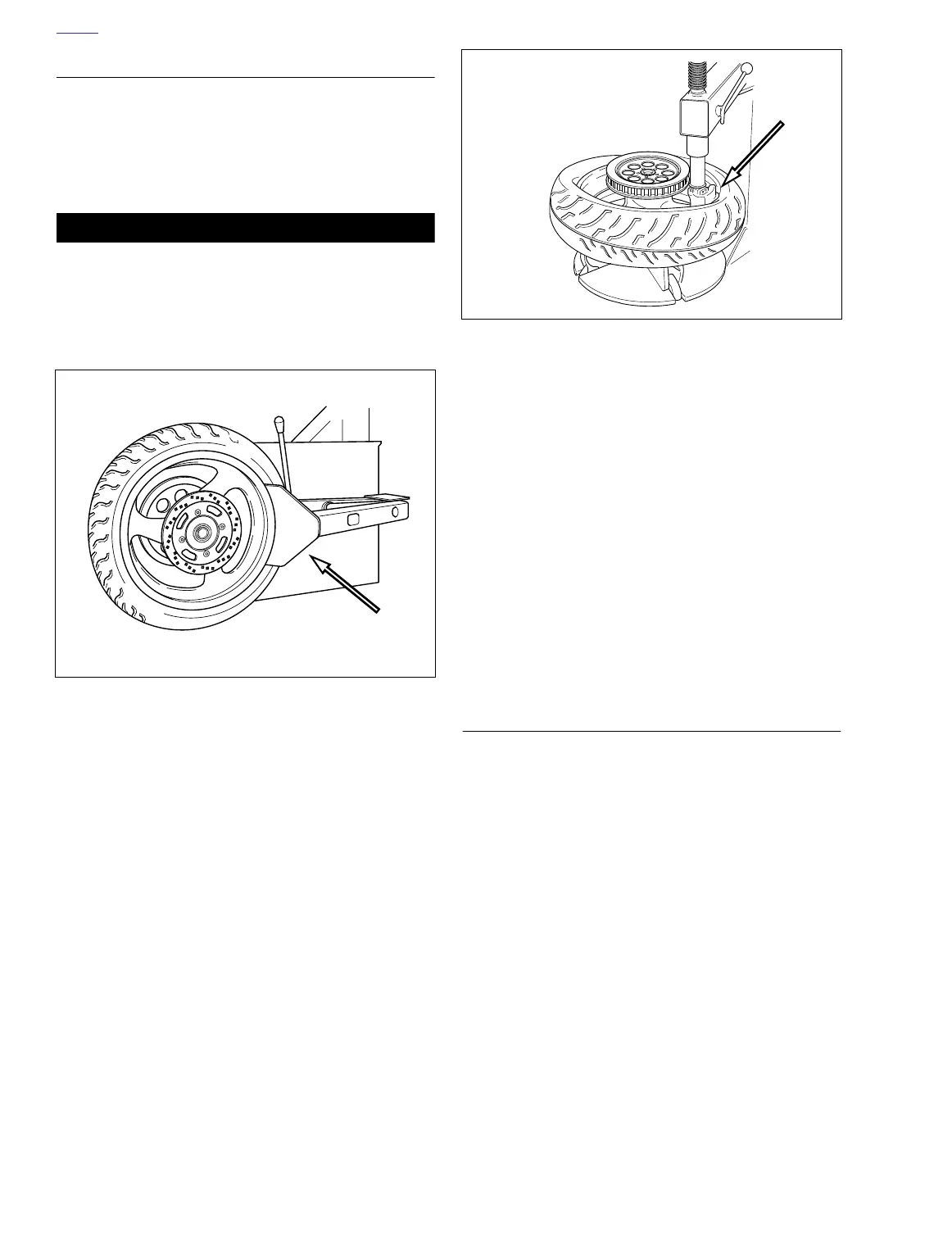

5. See Figure 2-21. Install wheel onto jaws of tire machine.

Lubricate tire bead with soap solution.

6. Fit wedge over rim of wheel.

7. Pull bead up over rim in one spot and fit bead to wedge.

Spin wheel to draw full length of bead over rim and off

wheel. Do not use excessive force when starting bead

over rim.

IMPORTANT NOTE

Follow the tire machine manufacture’s recommendation

for the correct placement of the bead on the mandrel.

Incorrect mounting may damage the bead and ruin the

tire.

8. If necessary, repeat for opposite bead and remove tire

from wheel.

9. Remove valve stem if it is damaged or leaks.

10. Mount tire on TIRE SPREADER (Part No. HD-21000) for

inspection and repair procedures.

CLEANING AND INSPECTION

1. Clean inside of tire.

2. If rim is dirty or corroded, clean with a stiff wire brush.

3. Inspect tire for wear and damage. Replace worn tires.

See 1.8 TIRES AND WHEELS.

Figure 2-20. Loosening Beads from Rim Flange (Typical)

a0207x2x

Figure 2-21. Tire Machine Pulling Bead Off Rim

a0208x2x

Loading...

Loading...