2007 Buell P3: Chassis 2-29

HOME

DISASSEMBLY

1. See Figure 2-39. Use BRAKE CALIPER PISTON

REMOVER (Part No. B-42887) to pull the two pistons

from caliper bores.

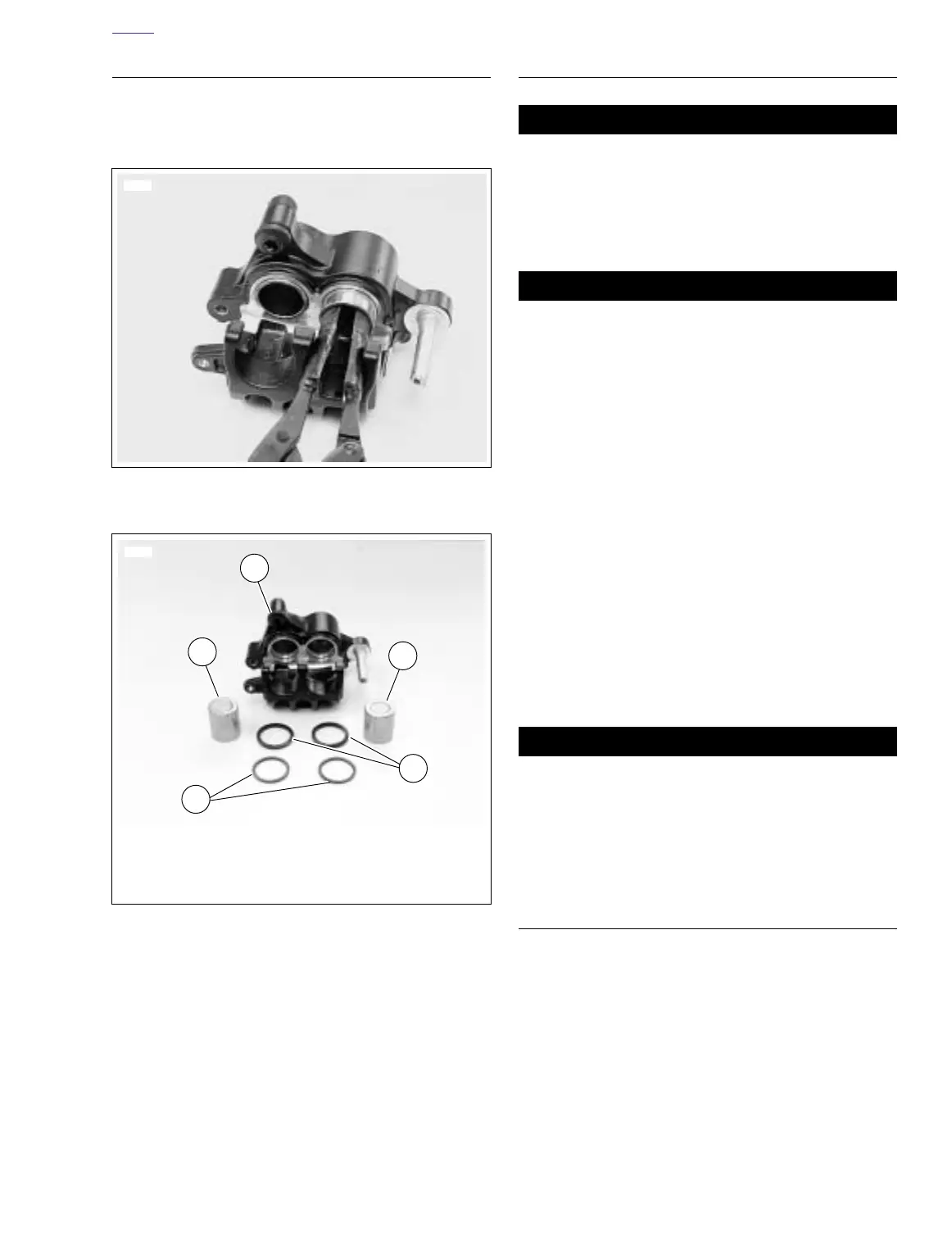

2. See Figure 2-40. Remove piston outer seals (4) and

inner seals (3) from their respective grooves in caliper.

Discard seals.

3. Check bleeder valve (metric). Remove and replace if

damaged.

CLEANING AND INSPECTION

Use denatured alcohol to clean brake system compo-

nents. Do not use mineral-based solvents (such as gaso-

line or paint thinner), which will deteriorate rubber parts

even after assembly. Deterioration of these components

can cause brake failure, which could result in death or

serious injury. (00291a)

Compressed air can pierce the skin and flying debris from

compressed air could cause serious eye injury. Wear

safety glasses when working with compressed air. Never

use your hand to check for air leaks or to determine air

flow rates. (00061a)

1. Clean all parts with denatured alcohol or D.O.T. 4

BRAKE FLUID. Do not contaminate with mineral oil or

other solvents. Wipe dry with a clean, lint free cloth. Blow

out drilled passages and bore with a clean air supply. Do

not use a wire or similar instrument to clean drilled pas-

sages.

2. Carefully inspect all components. Replace any parts that

appear damaged or worn. Do not hone caliper piston

bore.

3. Inspect brake rotor.

a. Measure rotor thickness. Replace if minimum thick-

ness is less than 0.180 in. (4.5 mm).

b. Check rotor surface. Replace if warped or badly

scored.

Always replace brake pads in complete sets for correct

and safe brake operation. Improper brake operation

could result in death or serious injury. (00111a)

4. Inspect brake pads for damage or excessive wear.

Replace both pads as a set if the friction material of

either pad is worn to 0.040 in. (1.0 mm) or less.

ASSEMBLY

1. See Figure 2-40. Install pistons and O-rings.

a. Apply a light coat of D.O.T. 4 BRAKE FLUID to

seals, pistons and caliper piston bores.

b. Install two new seals (4) in outer grooves of each

piston bore.

c. Install two new seals (3) in inner grooves of each

piston bore.

d. Install pistons (2) in each piston bore.

2. Install a new bleeder valve (metric) if necessary. Tighten

to 36-60 in-lbs (4-7 Nm).

Figure 2-39. Removing Pistons

Figure 2-40. Caliper O-rings and Pistons

7699

7700

1

2

2

3

4

1. Caliper

2. Piston (2)

3. Inner seals

4. Outer seals

Loading...

Loading...