2007 Buell P3: Engine 3-43

HOME

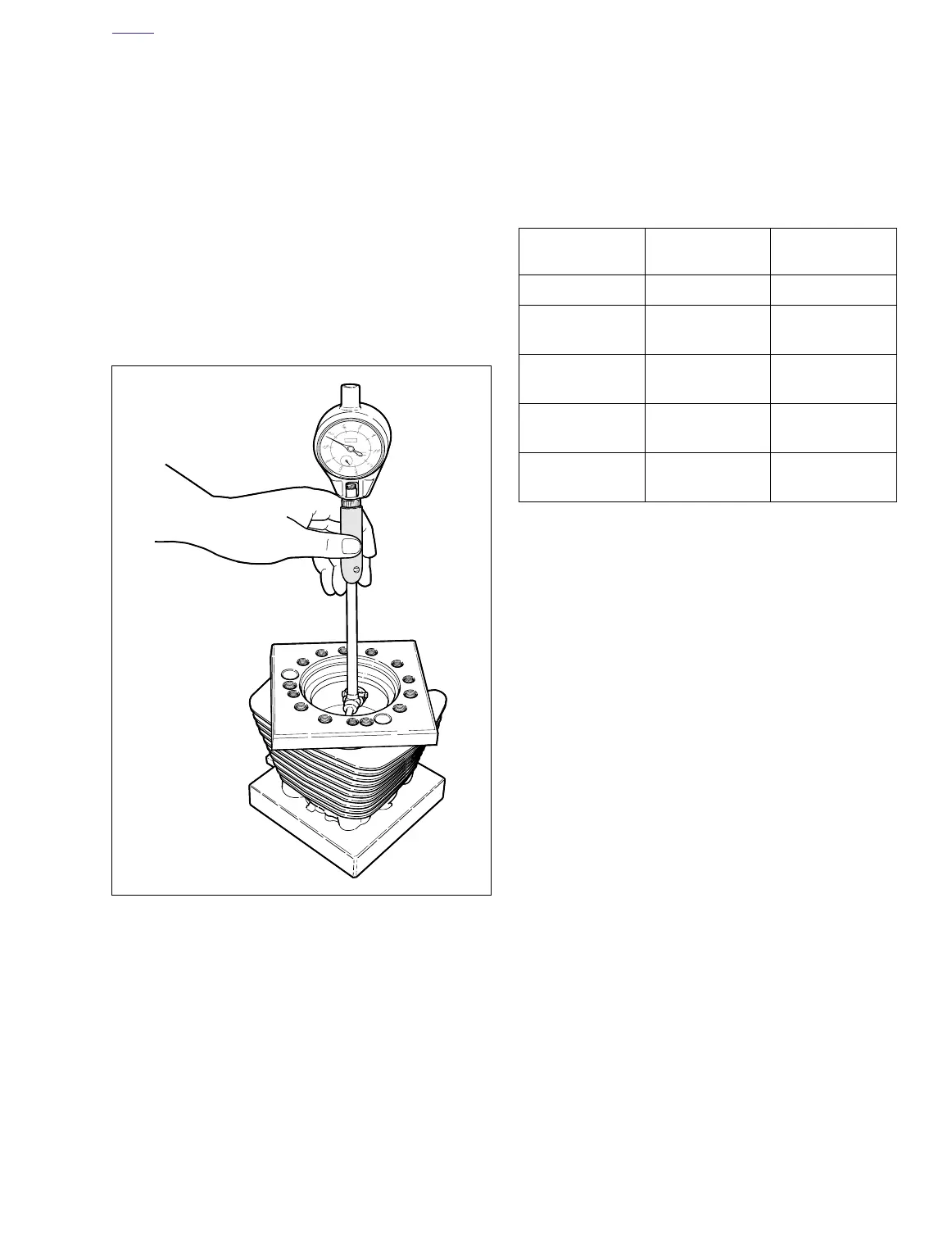

Measuring Cylinder Bore

1. Remove any burrs from the cylinder gasket surfaces.

2. See Figure 3-74. Install a head gasket, base gasket and

o-rings, and CYLINDER TORQUEPLATES (Part No. HD-

33446A) and XL EVOLUTION TORQUE PLATE BOLTS

(Part No. HD-33446-86). Tighten the bolts using the

same method used when installing the cylinder head

screws. See 3.5 CYLINDER HEAD.

NOTE

Torque plates, properly tightened and installed with gaskets,

simulate engine operating conditions. Measurements will vary

as much as 0.001 in. (0.025 mm) without torque plates.

3. See Figure 3-74. Take cylinder bore measurement in ring

path, starting about 0.50 in. (12.7 mm) from top of cylin-

der, measuring from front to rear and then side to side.

Record readings.

4. Repeat measurement at center and then at bottom of

ring path. Record readings. This process will determine if

cylinder is out-of-round and will also show any cylinder

taper or bulge.

5. Refer to Table 3-25. If cylinder is not scuffed or scored

and is within service limit, see next section, FITTING

PISTON RINGS.

NOTE

If piston clearance exceeds service wear limit, cylinders

should be re-bored and/or honed to next standard oversize,

and refitted with the corresponding piston and rings. Do not fit

piston tighter than 0.0007 in. (0.0178 mm). See 3.1 SPECIFI-

CATIONS.

Measuring Piston

Because of their complex shape, the pistons cannot be accu-

rately measured with standard measuring instruments.

Pistons have an elliptical shape when viewed from the top

and are barrel-shaped when viewed from the side. This barrel

shape is not symmetrical.

Any damage to the piston will change its shape, which will

lead to problems.

Figure 3-74. Measuring Cylinder Bore Using Torque

Plates (Part No. HD-33446A)

b0306x3x

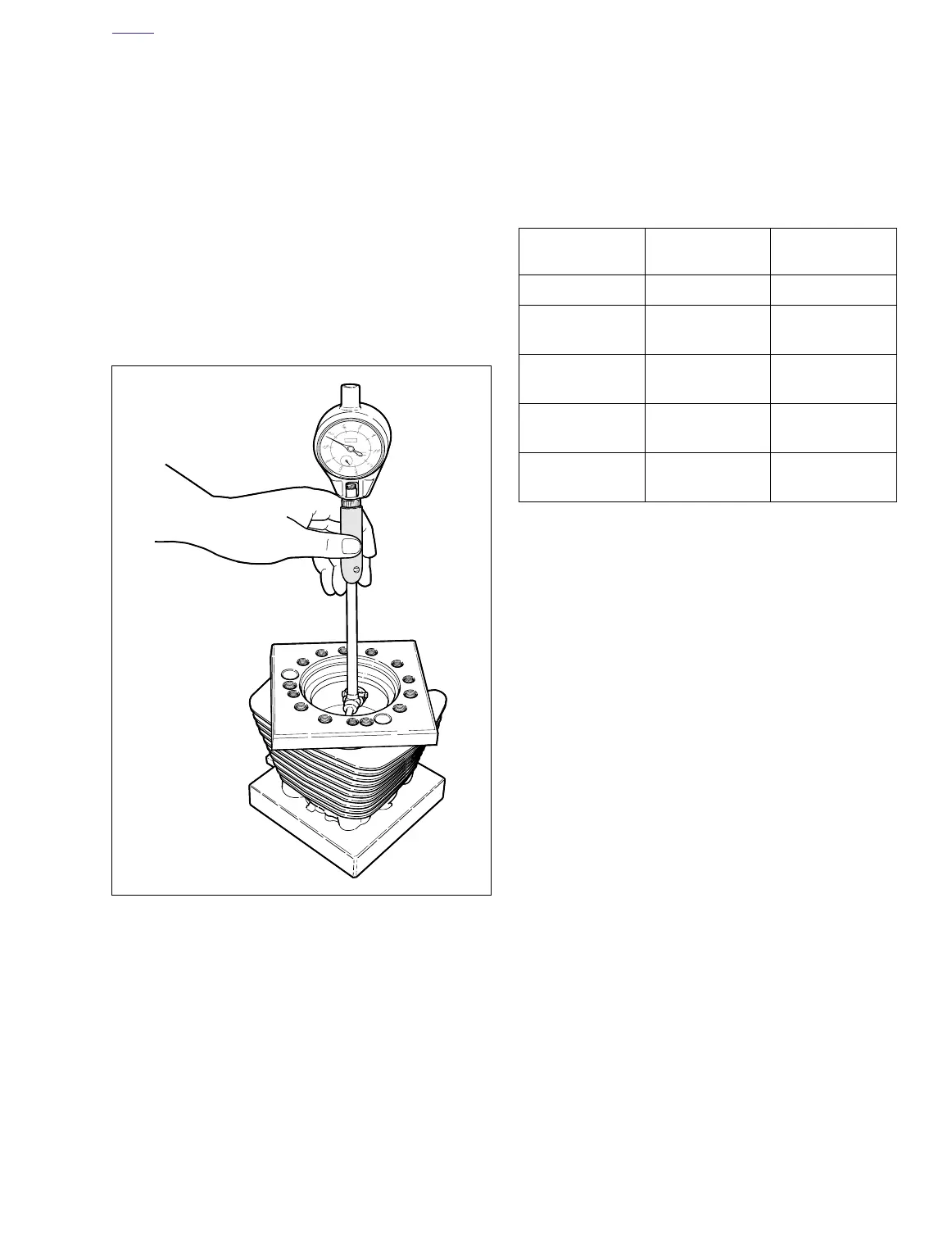

Table 3-25. Cylinder Bore

Service Wear Limits

BORE SIZES IN. MM

Standard bore 3.5008 88.9203

0.005 in. OS bore

(0.127 mm)

3.5050 89.0270

0.010 in. OS bore

(0.254 mm)

3.5100 89.1540

0.020 in. OS bore

(0.508 mm)

3.5200 89.4080

0.030 in. OS bore

(0.762 mm)

3.5300 89.6620

Loading...

Loading...