3-46 2007 Buell P3: Engine

HOME

NOTE

The same piston may be used if cylinder bore was not

changed, unless it is scuffed or grooved. If re-using piston,

replace piston rings and hone the cylinder walls with a No.

240 grit flexible hone to facilitate ring seating.

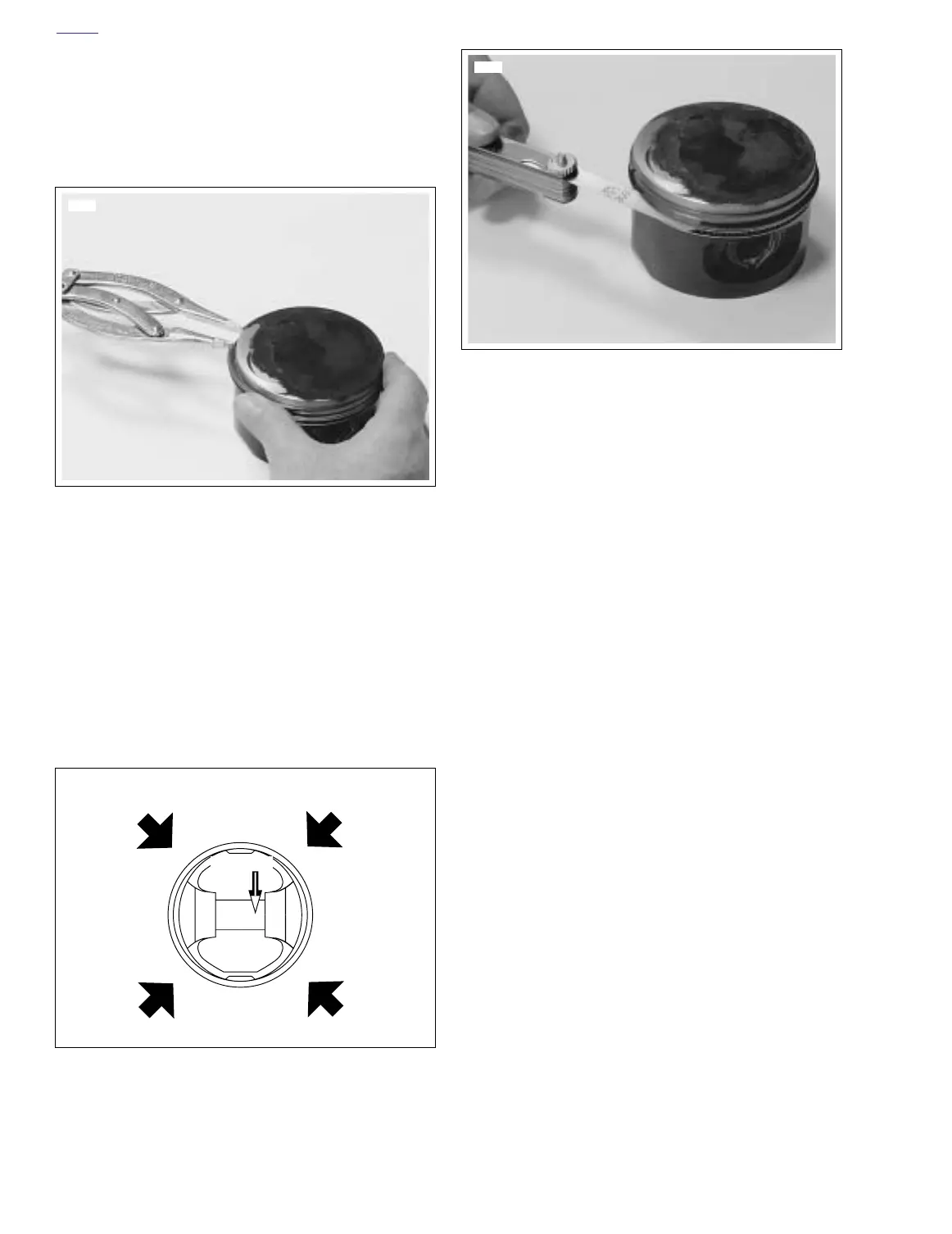

2. See Figure 3-77. Apply engine oil to piston grooves. Use

TRANSMISSION SHAFT RETAINING RING PLIERS

(Part No. J-5586) to slip compression rings over piston

into their respective grooves. Be extremely careful not to

over expand, twist rings or damage piston surface when

installing rings.

NOTE

Install second compression ring with dot towards top.

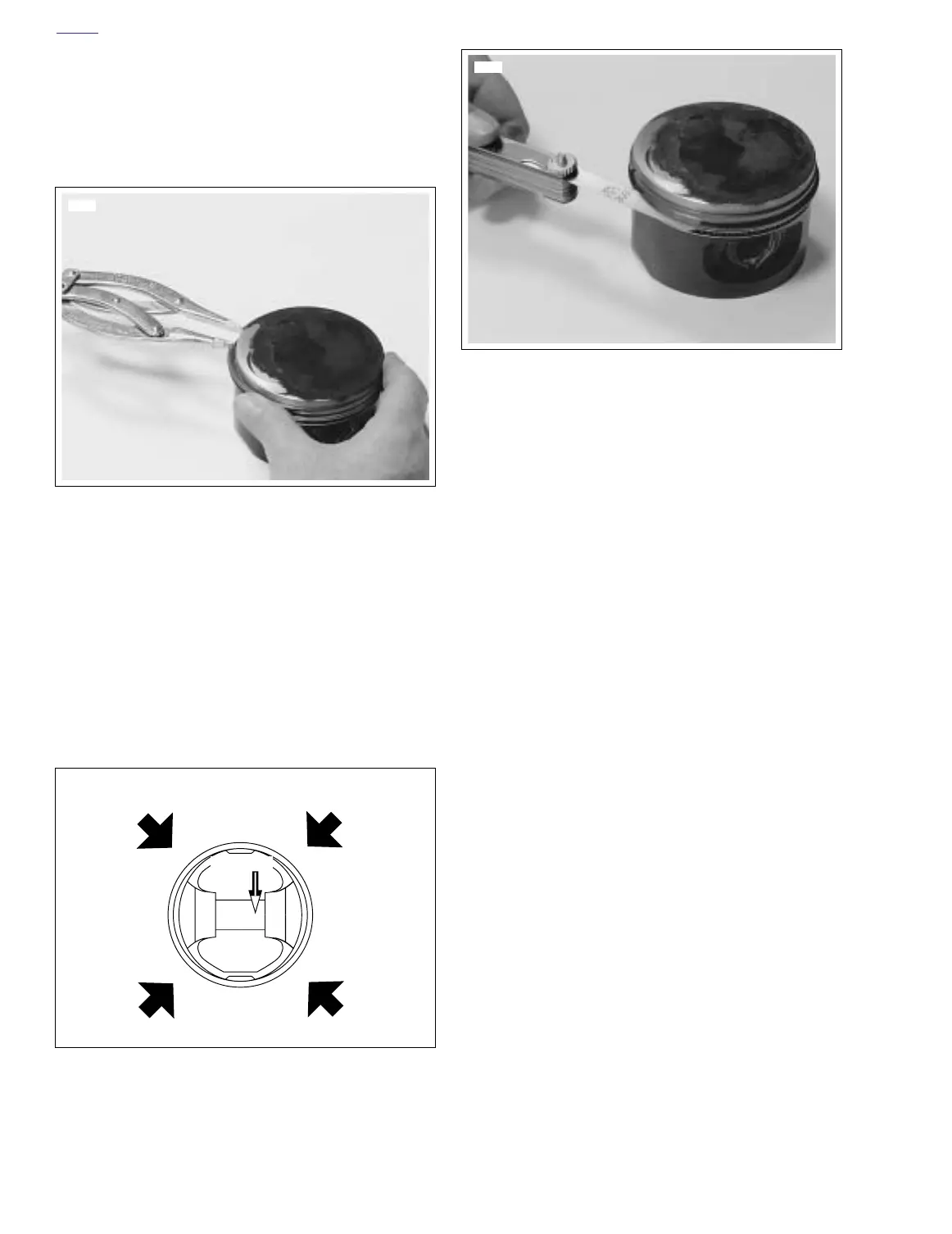

3. See Figure 3-78. Install rings so end gaps of adjacent

rings are a minimum of 90° apart. Ring gaps are not to

be within 10° of the thrust face centerline.

4. See Figure 3-79. Check for proper side clearance with

thickness gauge, as shown. See 3.1 SPECIFICATIONS.

NOTE

If the ring grooves are clean and the side play is still not cor-

rect, replace the rings, the piston or both.

Figure 3-77. Installing Piston Rings using Transmission

Shaft Retaining Ring Pliers (Part No. J-5586)

Figure 3-78. Ring End Gap Position

6613

x0486x3x

Piston

Pin

Position ring end gaps at arrows

Front

Rear

Figure 3-79. Measuring Ring Clearance in Groove

6614

Loading...

Loading...