3-64 2007 Buell P3: Engine

HOME

REMOVAL/DISASSEMBLY

11WARNING1WARNING

Compressed air can pierce the skin and flying debris

from compressed air could cause serious eye injury.

Wear safety glasses when working with compressed air.

Never use your hand to check for air leaks or to deter-

mine air flow rates. (00061a)

1. See Figure 3-103. Thoroughly clean area around gear-

case cover and tappets. Blow loose dirt from crankcase

with compressed air.

2. Remove any parts that will interfere with gearcase disas-

sembly.

3. See 3.5 CYLINDER HEAD. Remove push rods.

4. See 3.14 HYDRAULIC LIFTERS. Remove hydraulic lift-

ers.

5. Check for minimum cam gear end play. Record readings.

6. See 7.8 IGNITION MODULE AND CAM POSITION

SENSOR. Remove cam position sensor and rotor from

gearcase cover.

7. Place a pan under gearcase to collect oil. Remove cover

screws. Carefully remove gearcase cover. Discard old

gasket.

NOTE

If cover does not come loose on removal of screws, tap lightly

with a plastic hammer. Never pry cover off.

8. Remove cam gears.

NOTE

Nut is secured by Loctite Threadlocker 271 (red) on the nut

threads.

9. Remove nut. Slide pinion gear and oil pump drive gear

off pinion shaft.

CLEANING AND INSPECTION

1. Thoroughly clean gearcase compartment, gearcase

cover and gears in solvent to remove oil and carbon

deposits.

11WARNING1WARNING

Compressed air can pierce the skin and flying debris

from compressed air could cause serious eye injury.

Wear safety glasses when working with compressed air.

Never use your hand to check for air leaks or to deter-

mine air flow rates. (00061a)

2. Blow out all cover oil passages and bushings with com-

pressed air.

3. Clean old gasket material from gearcase and cover faces

with cleaning solvent.

NOTE

Prior to changing any cam gears, check gear shaft fit within

corresponding bushings. Worn bushings can cause excessive

backlash.

Bushing Inspection

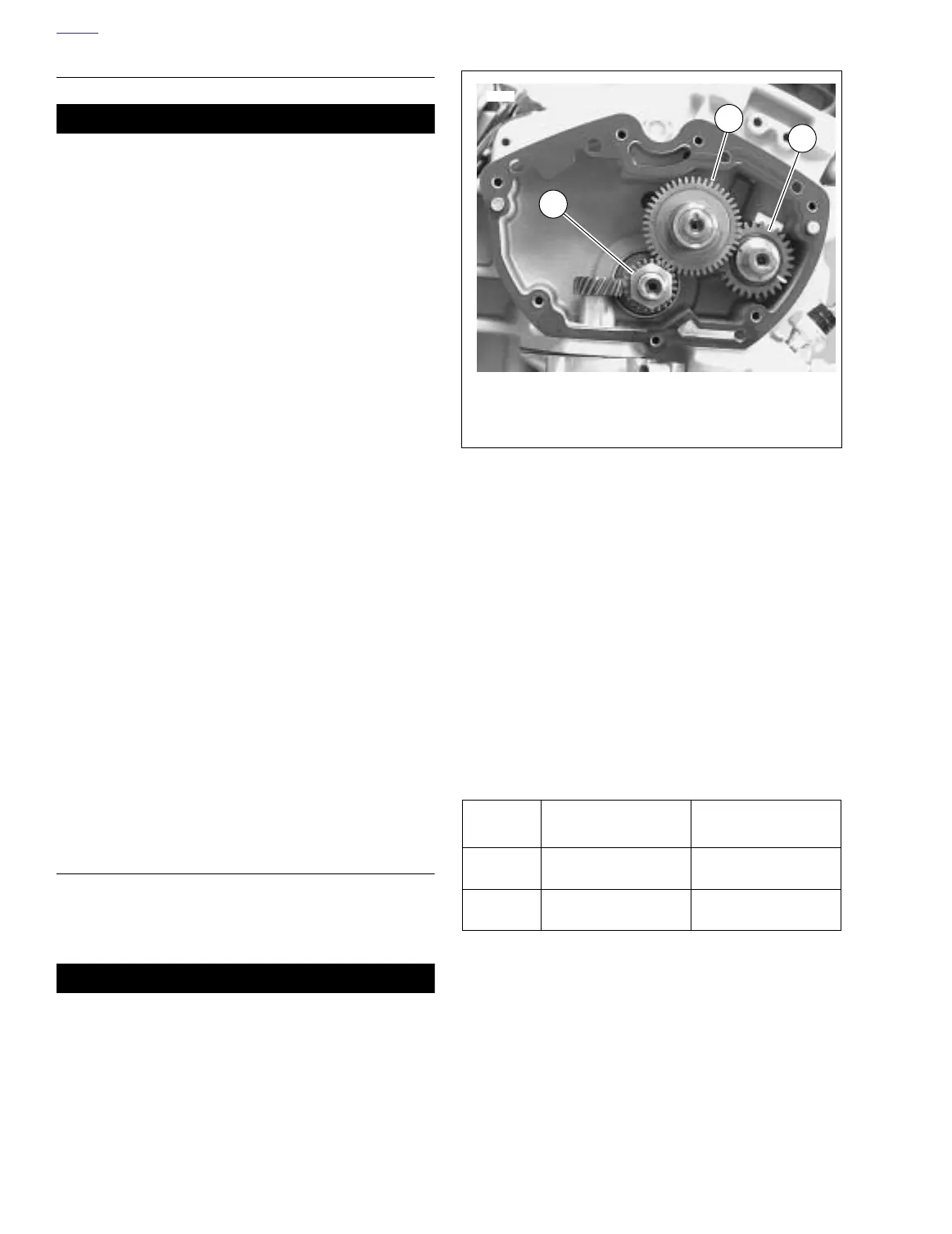

1. See Figure 3-103. Bushings are press fit in crankcase

and gearcase cover. Inspect each bushing against its

corresponding cam gear shaft or pinion gear shaft. See

Table 3-29.

NOTE

If Service Wear Limits are exceeded, replace crankcase set

and/or gearcase cover as required.

Figure 3-104. Cam and Pinion Gear Color Code Location

and Timing Mark Indexing

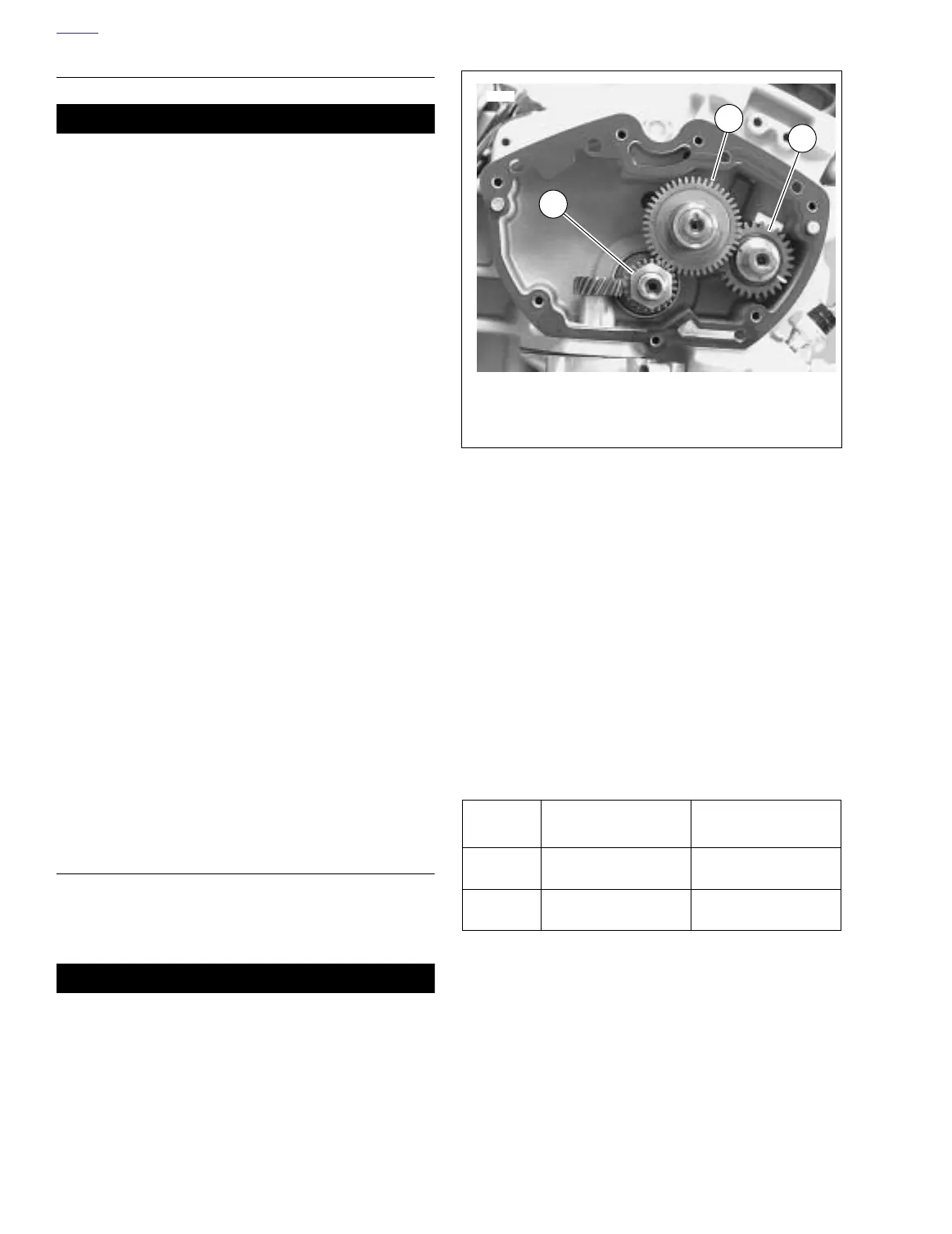

Table 3-29. Gear Shaft Specifications

GEAR

SHAFT

CORRECT

CLEARANCE

SERVICE WEAR

LIMIT

Cam 0.0007-0.0022 in.

(0.0178-0.0559 mm)

0.003 in.

(0.076 mm)

Pinion 0.0023-0.0043 in.

(0.0584-0.1092 mm)

0.0050 in.

(0.1270 mm)

1. Exhaust cam gear (1w)

2. Intake cam gear (2w)

3. Pinion gear

1

2

3

7687

Loading...

Loading...