HORN SWITCH

(1) Horn Switch

Place the main switch to the "ON"

position and press the horn switch to

sound the horn.

When the grain warning function is

activated, pressing the horn switch

stops the warning sounds.

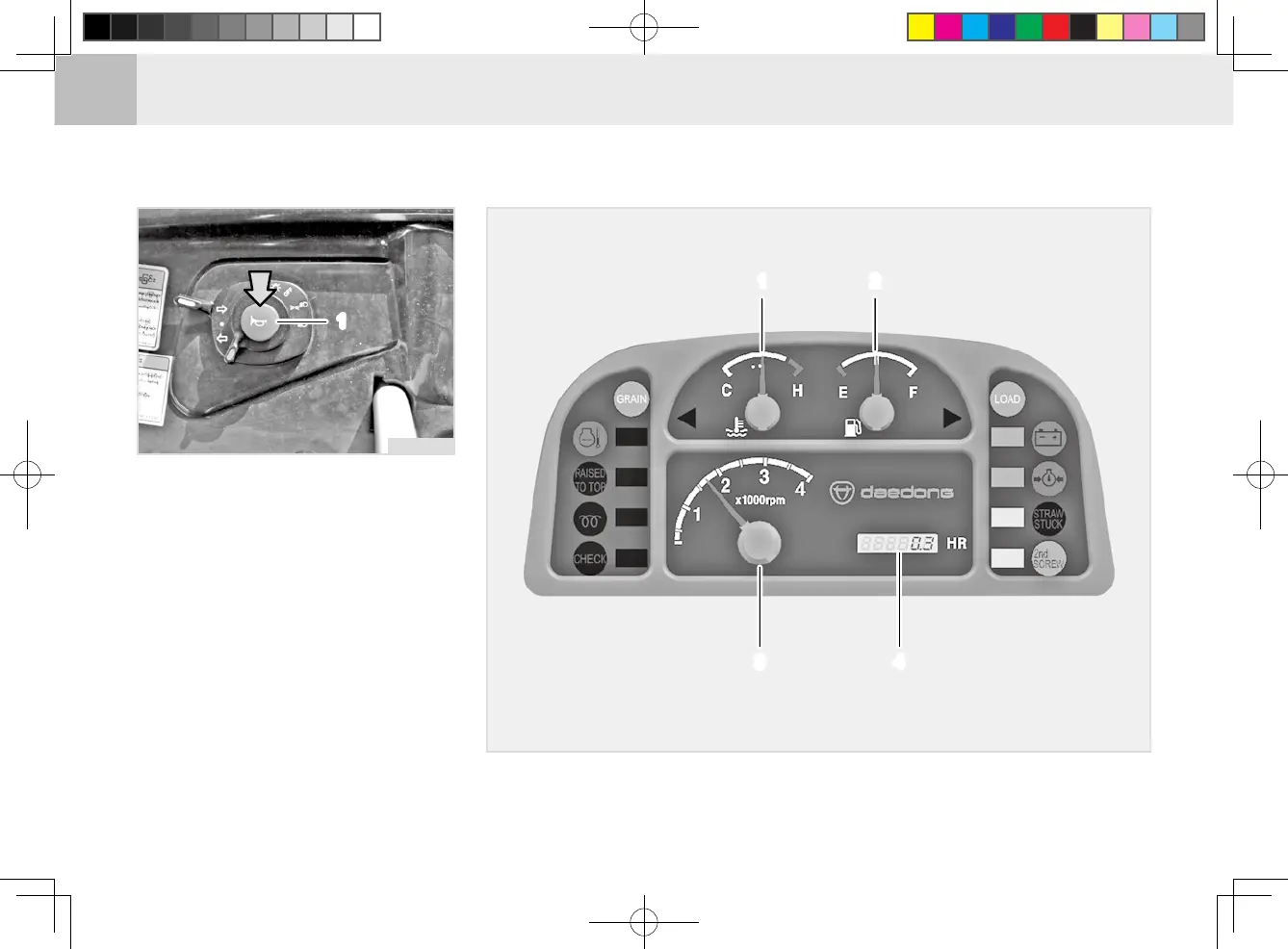

INSTRUMENT CLUSTER

(1) Coolant Temperature Gauge

(2) Fuel Gauge

(3) Tachometer

(4) Hour Meter

Loading...

Loading...