Troubleshooting

DeLaval voluntary milking system VMS

94897201.pdf2007-12-18

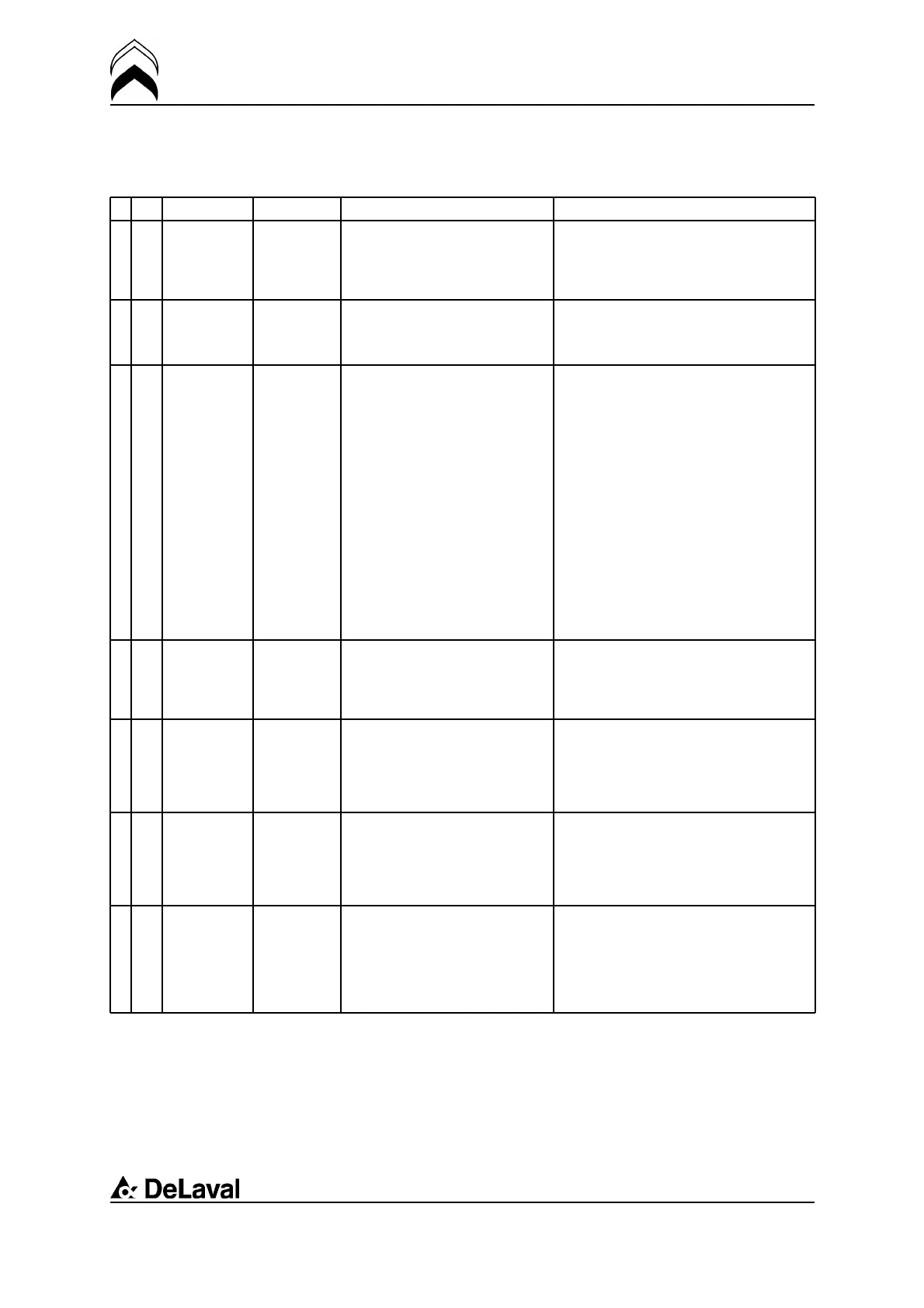

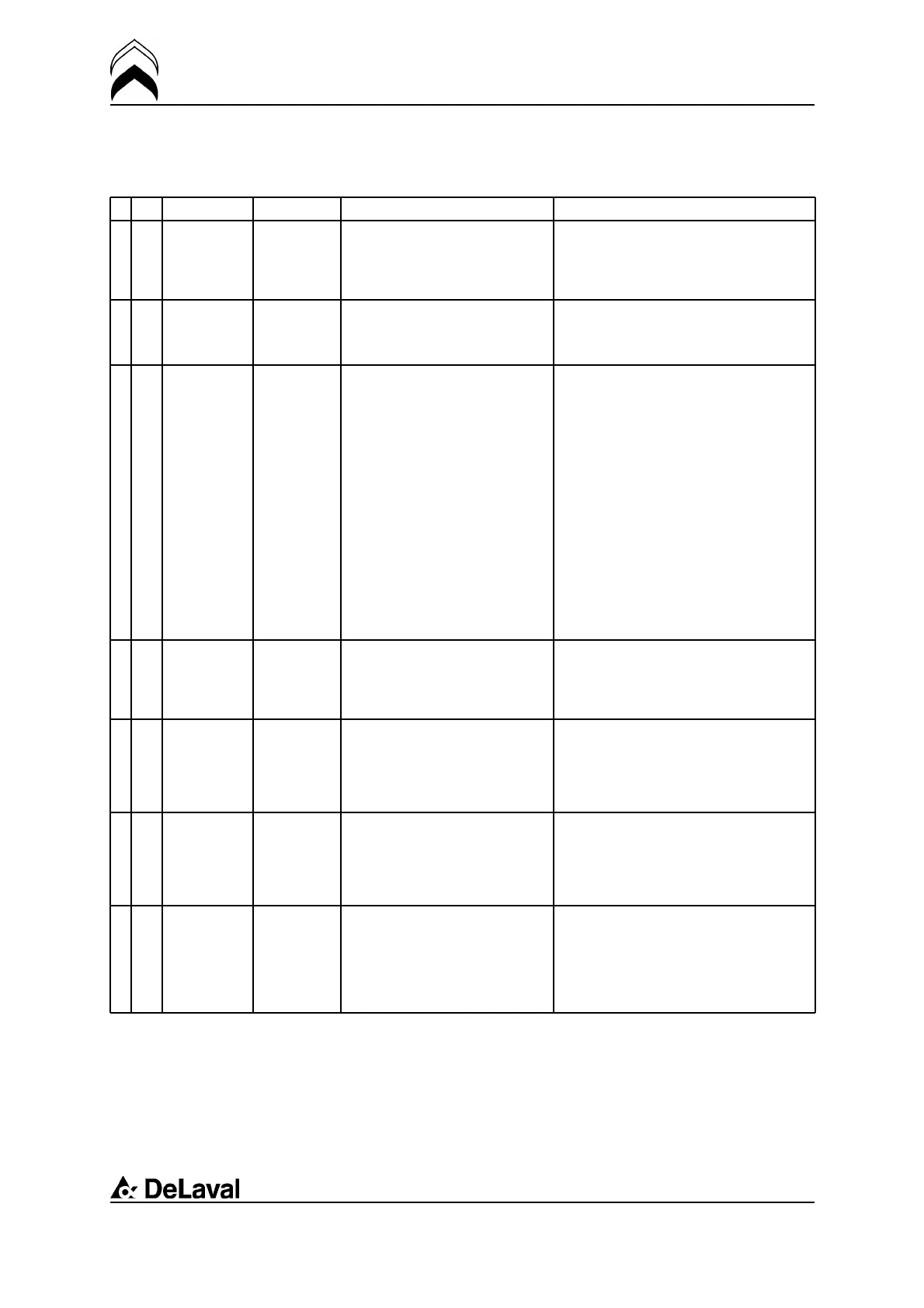

M m Alarm text Type Meaning ActionM m Alarm text Type Meaning Action

2 41 Please set

X CentreLas-

er =...

Y CentreLas-

er =...

Status

message

Applies to cup-centre tuning (touch

screen button "Cup Center Tuning"

in Robot Control window).

Information to service engineer only.2 41 Please set

X CentreLas-

er =...

Y CentreLas-

er =...

Status

message

Applies to cup-centre tuning (touch

screen button "Cup Center Tuning"

in Robot Control window).

Information to service engineer only.

2 42 Tune Cup

center done!

(Updating

database)

Status

message

See Major code 2, Minor code 41

above.

2 42 Tune Cup

center done!

(Updating

database)

Status

message

See Major code 2, Minor code 41

above.

2 51 Teat not

found for

milking

Deviation The robot failed to attach a

teatcup. The message includes the

cow number, cup number, and for

which teat the attachment failed.

A) If you are present at the milking station,

wait until the robot has tried to reattach the

teatcup. If the robot does not succeed in

attaching the cup, the milking will be

classified as "Incomplete". This means that

the cow will be allowed to return for a new

milking in a short while.

B) To avoid a milking being classified as

Incomplete, do the following:

- Wait until the robot is supporting the milk

tubes.

- Then use the "Start milking" buttons on

the touch screen to attach the missing

cup(s) by hand. Note: never move teatcups

without using the stop/start buttons.

If milkings are classified as Incomplete

frequently, follow the advice for "Mixed and

corrected: Cup attached to teat" above

(major code 2, minor code 13).

2 51 Teat not

found for

milking

Deviation The robot failed to attach a

teatcup. The message includes the

cow number, cup number, and for

which teat the attachment failed.

A) If you are present at the milking station,

wait until the robot has tried to reattach the

teatcup. If the robot does not succeed in

attaching the cup, the milking will be

classified as "Incomplete". This means that

the cow will be allowed to return for a new

milking in a short while.

B) To avoid a milking being classified as

Incomplete, do the following:

- Wait until the robot is supporting the milk

tubes.

- Then use the "Start milking" buttons on

the touch screen to attach the missing

cup(s) by hand. Note: never move teatcups

without using the stop/start buttons.

If milkings are classified as Incomplete

frequently, follow the advice for "Mixed and

corrected: Cup attached to teat" above

(major code 2, minor code 13).

2 52 Teat not

found at

reattach

Deviation The teat was not found during

reattachment. The message

includes the cow number, cup

number, and for which teat the

reattachment was unsuccessful.

Follow the instructions under B for "Teat not

found for milking" above (Major code 2,

Minor code 51).

2 52 Teat not

found at

reattach

Deviation The teat was not found during

reattachment. The message

includes the cow number, cup

number, and for which teat the

reattachment was unsuccessful.

Follow the instructions under B for "Teat not

found for milking" above (Major code 2,

Minor code 51).

2 53 Teat position

not working

(too low)

Deviation The start position for this teat is too

close to the ground. The message

includes the cow number and

which teat that has a start position

too close to the ground. Robot will

proceed with next teat.

Reteach the start position for the teat.

It is possible that the VMS cannot handle

this cow due to the udder/teat being too

close to the ground. Check that the cow

fulfils the DeLaval udder criteria.

2 53 Teat position

not working

(too low)

Deviation The start position for this teat is too

close to the ground. The message

includes the cow number and

which teat that has a start position

too close to the ground. Robot will

proceed with next teat.

Reteach the start position for the teat.

It is possible that the VMS cannot handle

this cow due to the udder/teat being too

close to the ground. Check that the cow

fulfils the DeLaval udder criteria.

2 55 No camera

objects seen

during

attempt to

find teat

Deviation While searching for teats, the

locations software could not find

any objects at all in the camera

picture. This is not normal

operating performance.

If this rarely ever occurs, then no action is

required. If it occurs frequently, check that

the lasers are working and that the lower

arm can rotate around its axis. If either of

these fail, notify the service engineer.

Warning: Do not stare into the laser beams.

2 55 No camera

objects seen

during

attempt to

find teat

Deviation While searching for teats, the

locations software could not find

any objects at all in the camera

picture. This is not normal

operating performance.

If this rarely ever occurs, then no action is

required. If it occurs frequently, check that

the lasers are working and that the lower

arm can rotate around its axis. If either of

these fail, notify the service engineer.

Warning: Do not stare into the laser beams.

Service engineer only:

Check that the lasers are working.

- If the arm has not rotated properly, the

camera might be pointing to the floor.

-Check for dirt, damage or scratches on the

camera window.

-Clean the camera window if necessary.

Service engineer only:

Check that the lasers are working.

- If the arm has not rotated properly, the

camera might be pointing to the floor.

-Check for dirt, damage or scratches on the

camera window.

-Clean the camera window if necessary.

161(198)

Loading...

Loading...