Chapter 4 Parameters|

4-128 Revision Jan. 2009, 06EE, SW--PW V1.12/CTL V2.12

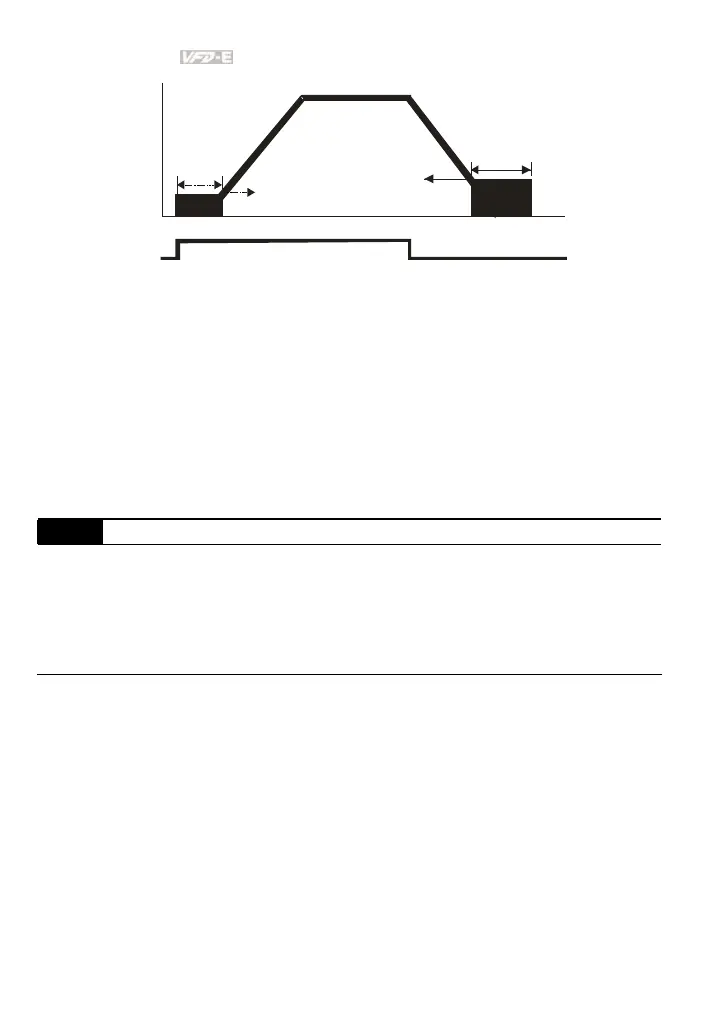

Run/Stop

ON

OFF

01.05

08.03

Output Frequenc

Minimum Output

Freque nc y

Start-Poin t for

DC Brake

Time du ri ng

St op ping

DC Brake Time

during Stopping

DC Brake Time

08.01

08.02

DC Brake during Start-up is used for loads that may move before the AC drive starts, such as

fans and pumps. Under such circumstances, DC Brake can be used to hold the load in

position before setting it in motion.

DC Brake during stopping is used to shorten the stopping time and also to hold a stopped load

in position, such as cranes and cutting machines. For high inertia loads, a brake resistor for

dynamic brake may also be needed for fast decelerations. Refer to appendix B for the

information of brake resistors.

08.04 Momentary Power Loss Operation Selection

Factory Setting: 0

Settings 0 Operation stops (coast to stop) after momentary power loss.

1 Operation continues after momentary power loss, speed search

starts with the Last Frequency.

2 Operation continues after momentary power loss, speed search

starts with the minimum frequency.

This parameter determines the operation mode when the AC motor drive restarts from a

momentary power loss.

The power connected to the AC motor drive may be off temporarily with unknown factors. This

parameter can restart the drive after momentary power loss.

Setting 1: the drive will operate by the last frequency before momentary power loss. It will

accelerate to the master frequency after the drive output frequency and the motor rotor’s

speed are synchronous. It is recommended to use this setting for those motor loads which

have a large inertia and small resistance to save time by restarting without waiting the flywheel

stops completely, such as machinery equipment with a large-inertia flywheel.

Loading...

Loading...